A photocatalyst spraying device for decoration

A technology of spraying device and photocatalyst, applied in spraying device, cleaning method and utensils, cleaning method using gas flow, etc., can solve the problems of difficult to form thin film, splashing around, adverse consequences, etc., to improve adhesion and uniform spraying operation , Improve the effect of spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

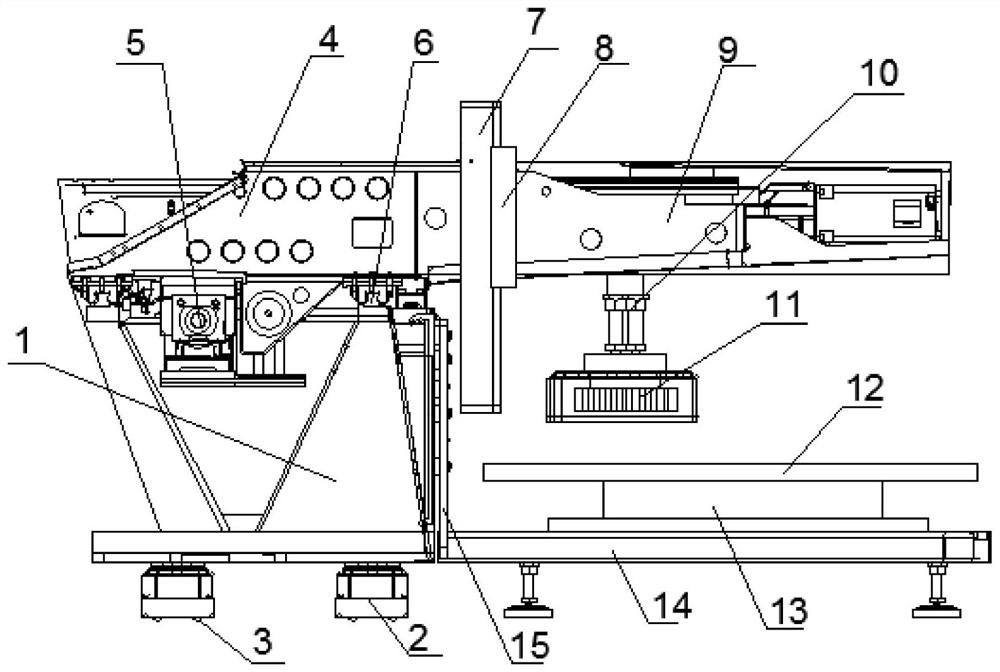

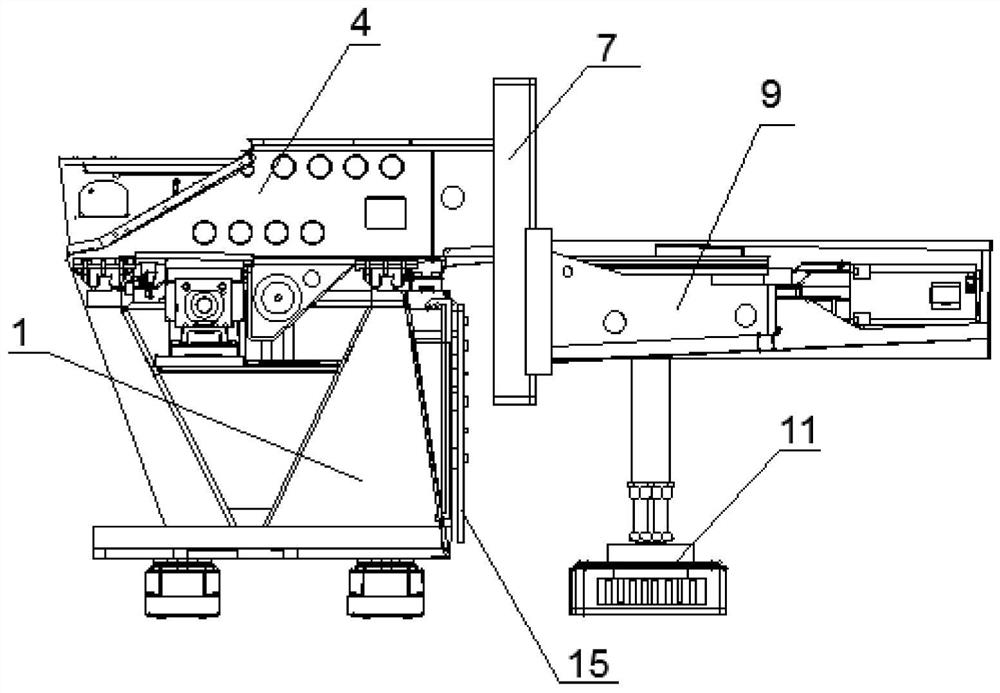

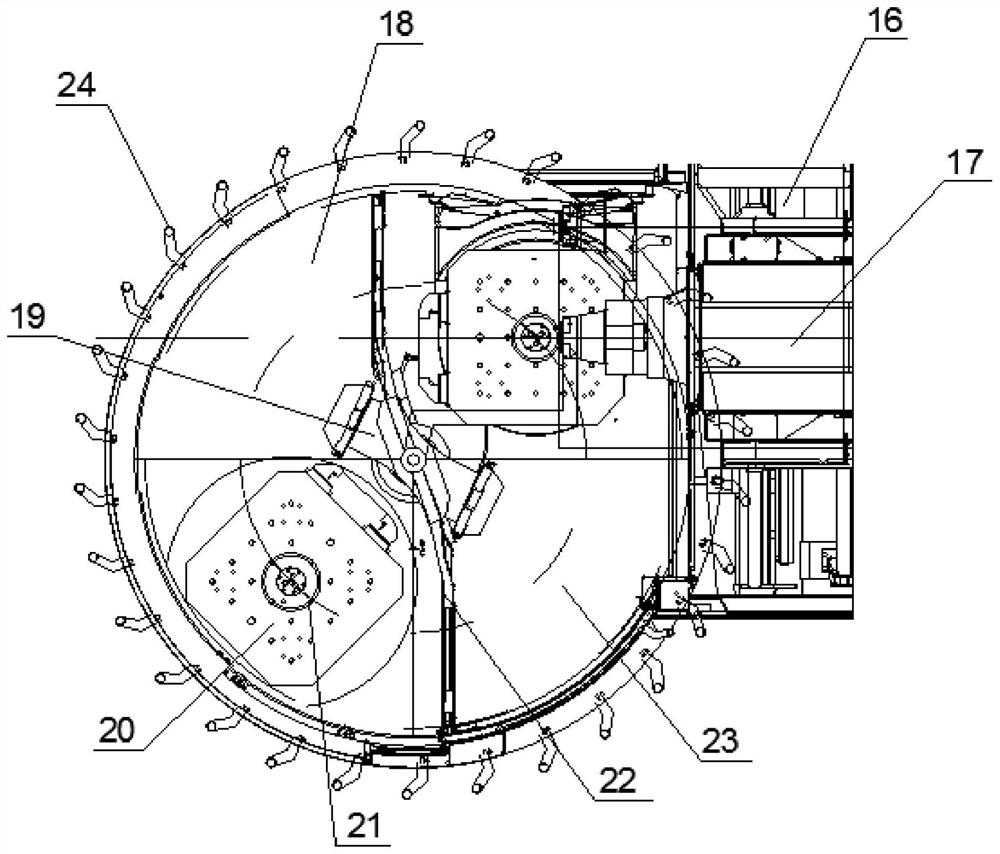

[0021] see Figure 1~3 , in an embodiment of the present invention, a photocatalyst spraying device for decoration, including a spraying machine base 1, a vertical sliding seat 7, a transverse beam 9 and a spraying plate mechanism 11, wherein, the spraying machine base 1 is connected with a vertical To the sliding seat 7, the vertical sliding seat is provided with the transverse beam 9 which can slide up and down, and the transverse beam 9 is provided with the spraying plate mechanism 11 which can move laterally, it is characterized in that the spraying The disk mechanism 11 comprises a spraying disk 18, a spraying cylinder 19 and a polishing assembly. The spraying disk is a rotatable disc structure, and at least one of the spraying cylinders 19 is arranged in the center of the spraying disk. The two ends of the spraying cylinder are spraying heads, and the spraying heads are towards the radially outer side of the spraying plate, and the polishing assembly between the two spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com