Shared construction platform for single pile and high pile cap foundation steel pipe pile planting of offshore wind power plant

A technology for offshore wind power and construction platforms, applied in infrastructure engineering, construction, etc., can solve problems such as uneven distribution of water depth, inability to fully utilize resources, and many resources, so as to ensure verticality and stability, and simple and convenient installation and dismantling. The effect of increasing the construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

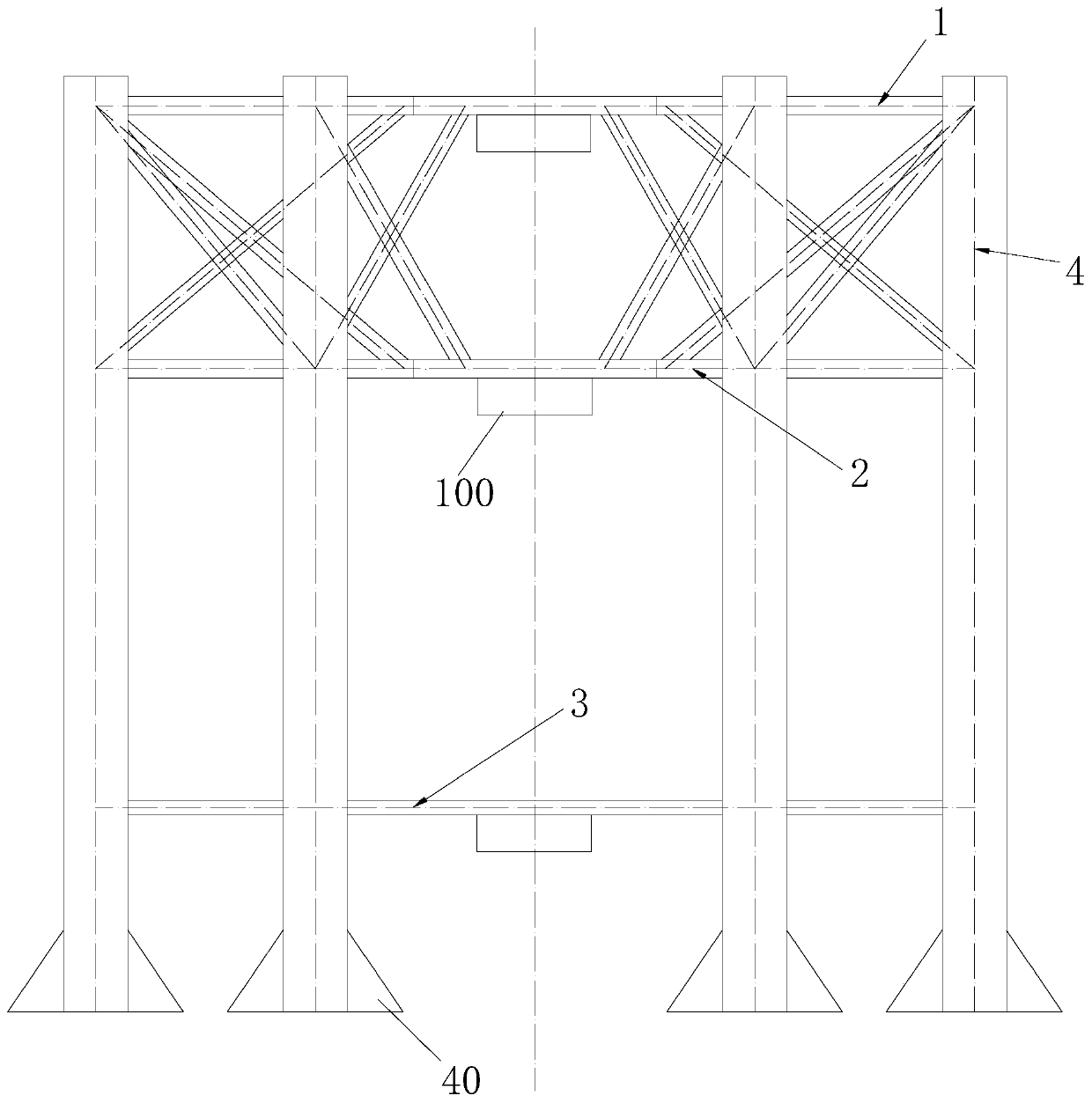

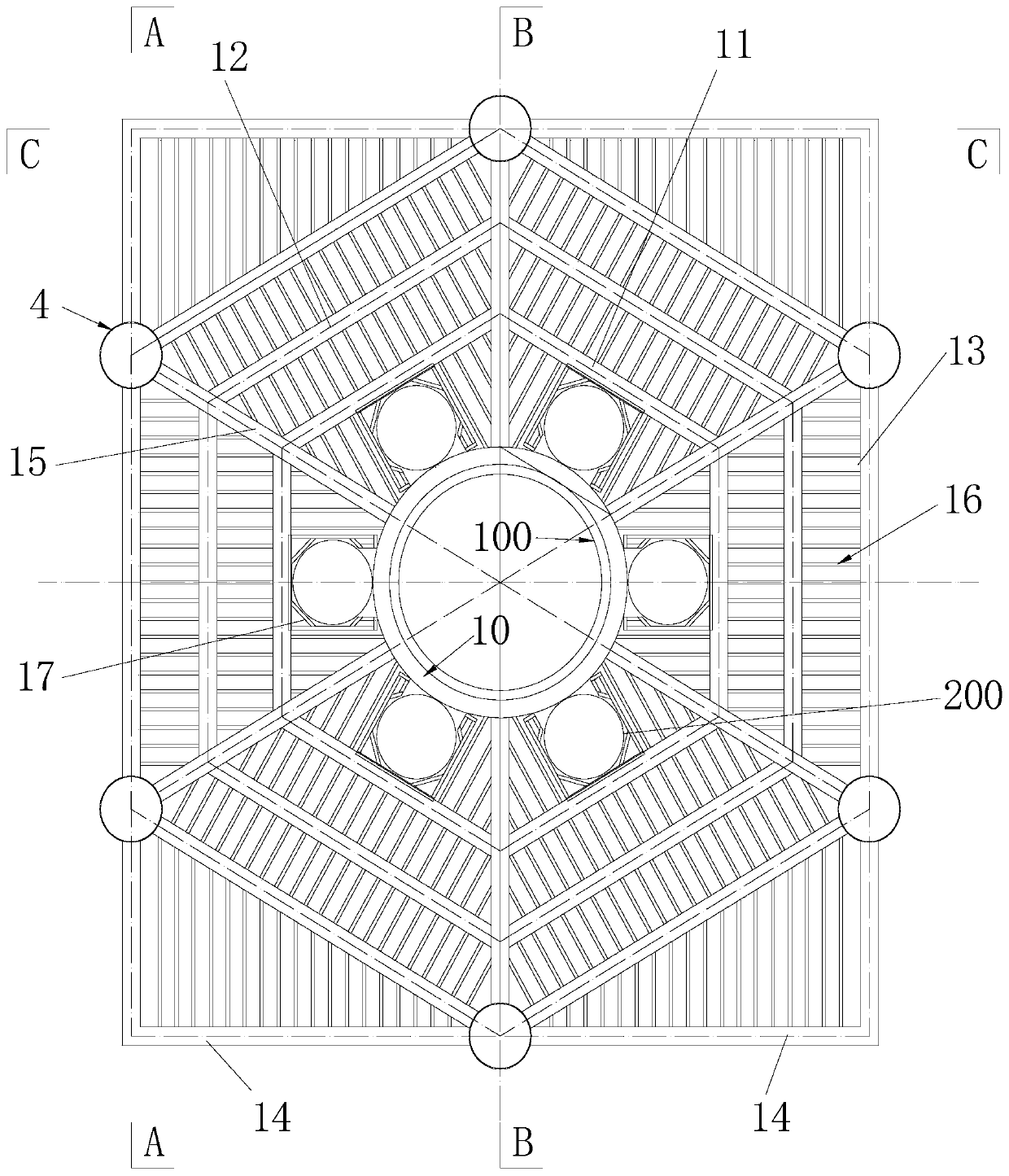

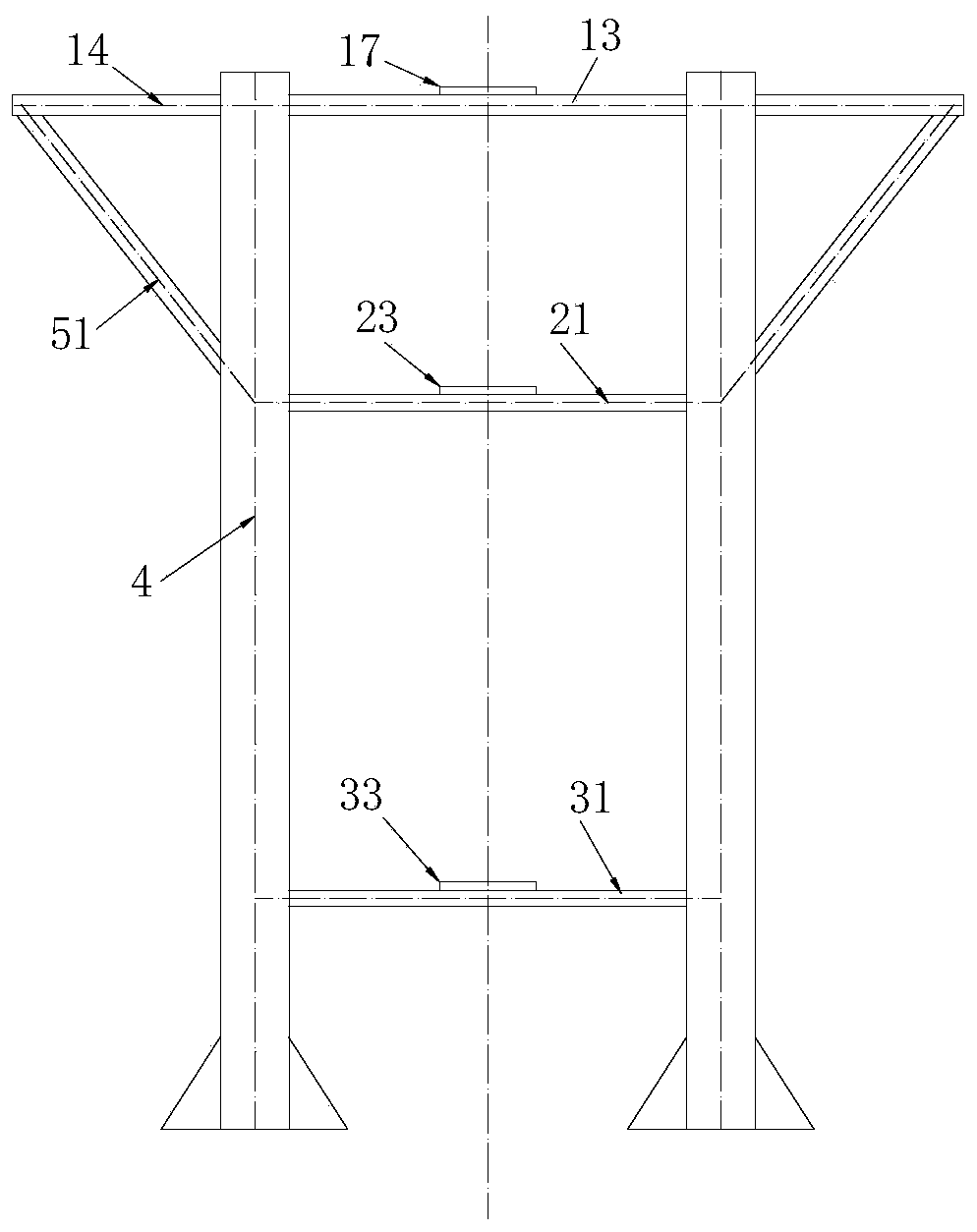

[0031] see Figure 1 to Figure 6 , the offshore wind power single pile and high pile cap foundation steel pipe pile planting shared construction platform of the present invention can be mainly used for offshore wind power implanted rock-socketed large-diameter single pile planting construction and implanted high pile cap foundation steel pipe Pile planting construction. The shared construction platform is supported by six auxiliary piles and includes six auxiliary pile sleeves 4 and a top platform 1 , a middle platform 2 and a lower platform 3 arranged on the six auxiliary pile sleeves 4 .

[0032] The six auxiliary pile casings 4 are arranged on the same circular line with a diameter of 30m in the form of a regular hexagon; the auxiliary pile casings 4 are made of φ2200×28mm steel pipes with a height of 32m, and each of the six auxiliary pile casings 4 A pin hole and a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com