Fastener for construction

A technology of fasteners and components, applied in the field of construction components, can solve problems such as low safety, labor consumption, complicated procedures, etc., and achieve the effects of improving construction efficiency, construction safety, and shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is a description of embodiments of the present invention.

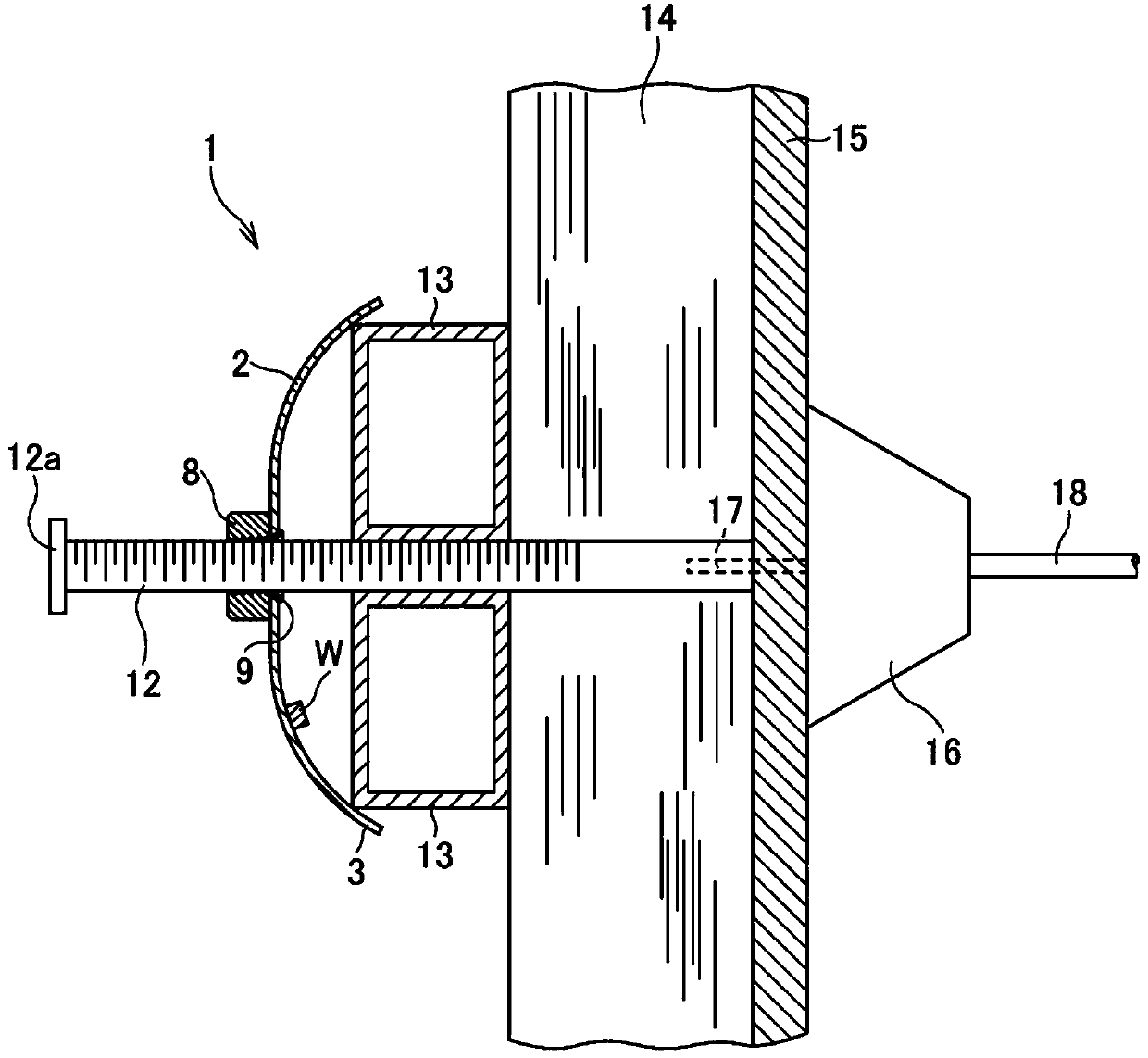

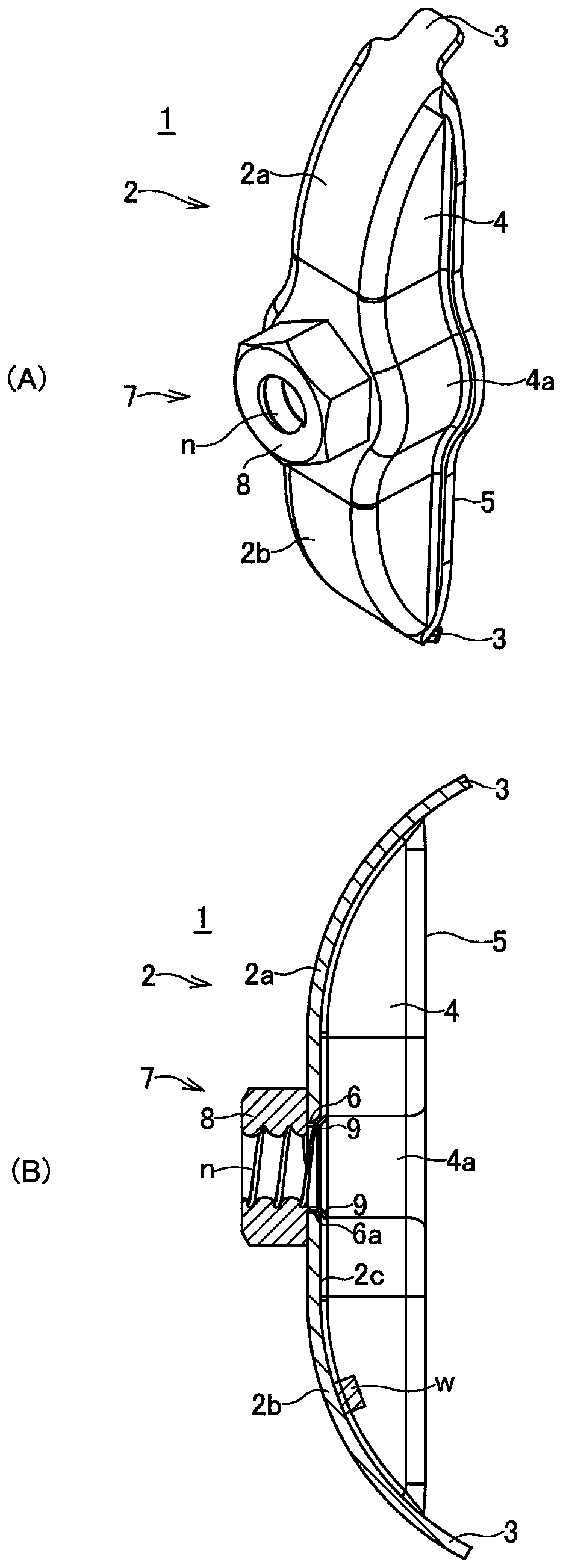

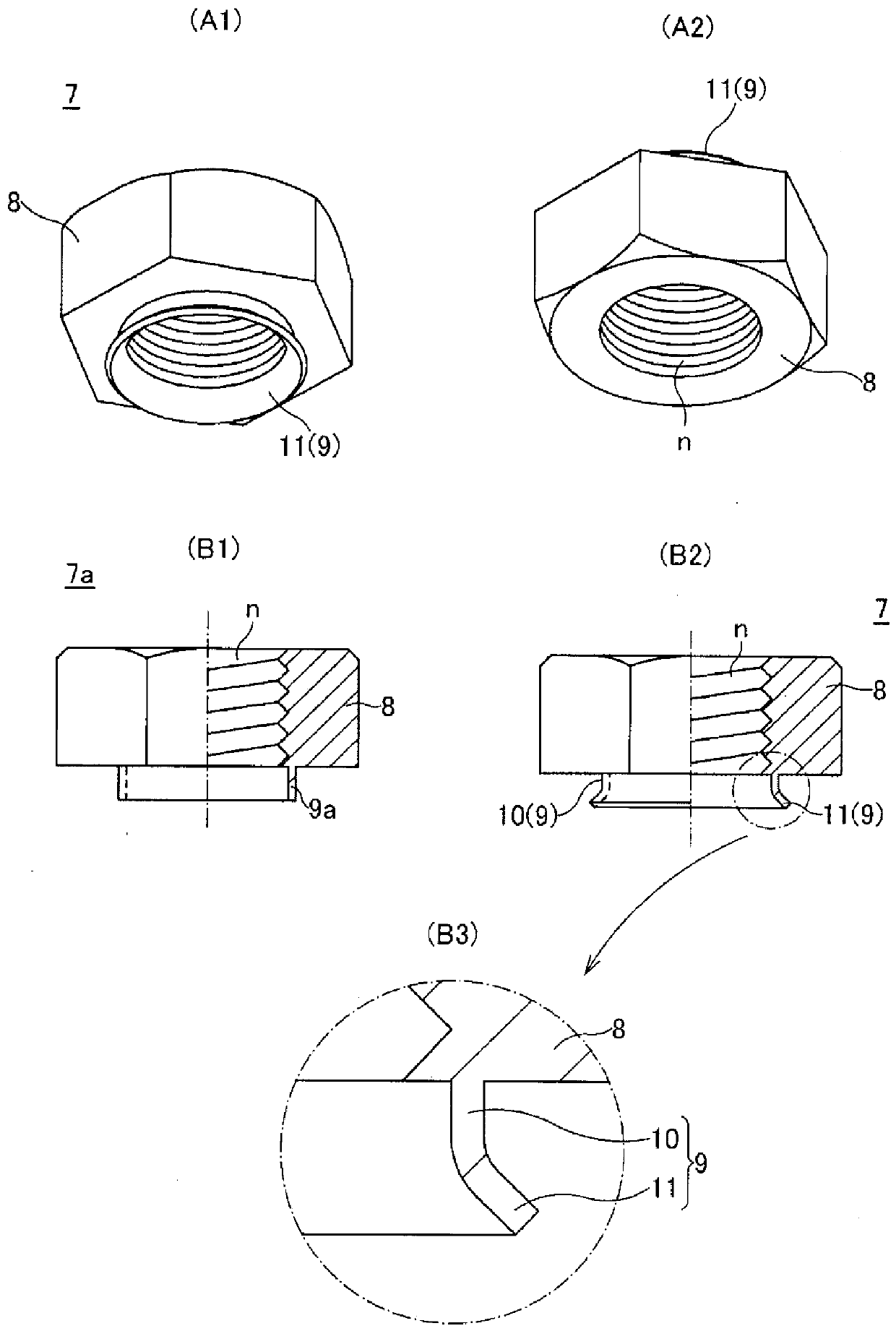

[0038] figure 1 This is a partial vertical cross-sectional view of the used state of the fastener for construction (hereinafter referred to as the fastener) 1 of the present invention. An example of a construction method: when constructing concrete walls, such as figure 1 As shown in the figure, a pair of left and right frames 15 (not shown on the right side) perpendicular to the base surface are installed in parallel at the designed positions, and a plurality of angle bars 14 are vertically fixed on the outer side of each frame 15, and are arranged on the outer side of the angle bars 14. The upper and lower square tubes 13 arranged perpendicular to the angle material 14 and horizontally, the screw 12 passing between the upper and lower square tubes 13, the screw thread of the screw 12, and the main body including the holding member 2 for holding the square tube 13 fixed. The inventive fastene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com