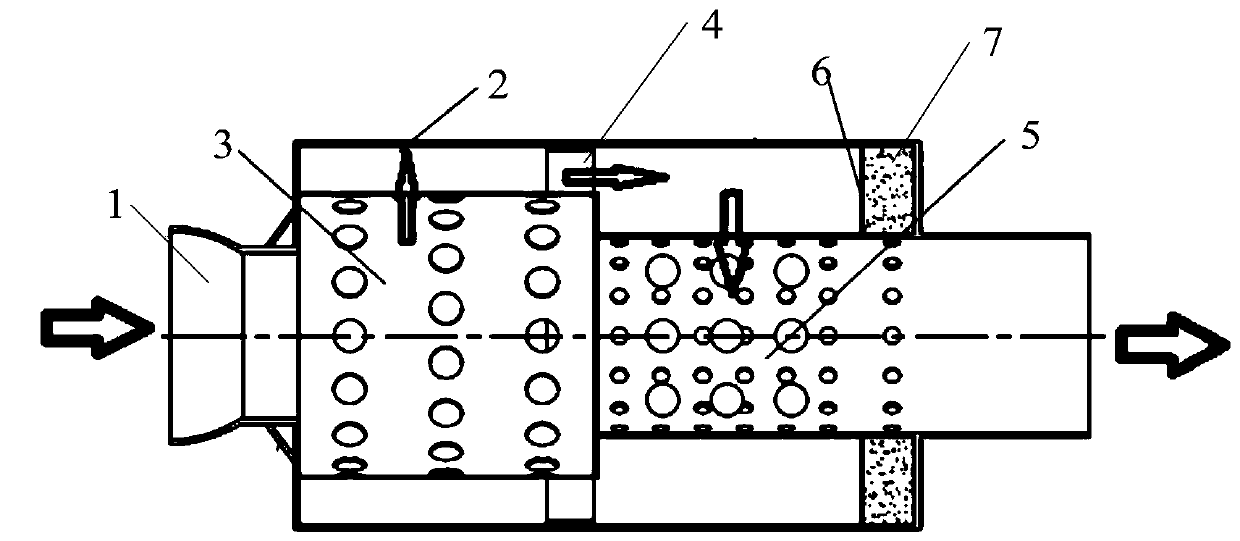

Silencer and engine

A muffler and noise reduction technology, which is applied in the direction of machines/engines, engine components, noise reduction devices, etc., can solve the problems that the muffler is easy to be limited by temperature, easy to age, and the sound-absorbing cotton is easy to deform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

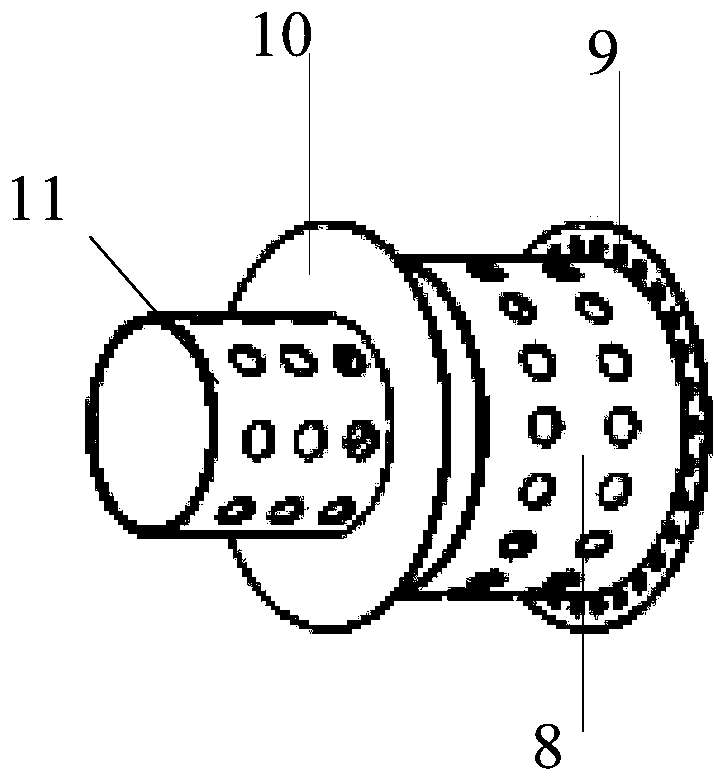

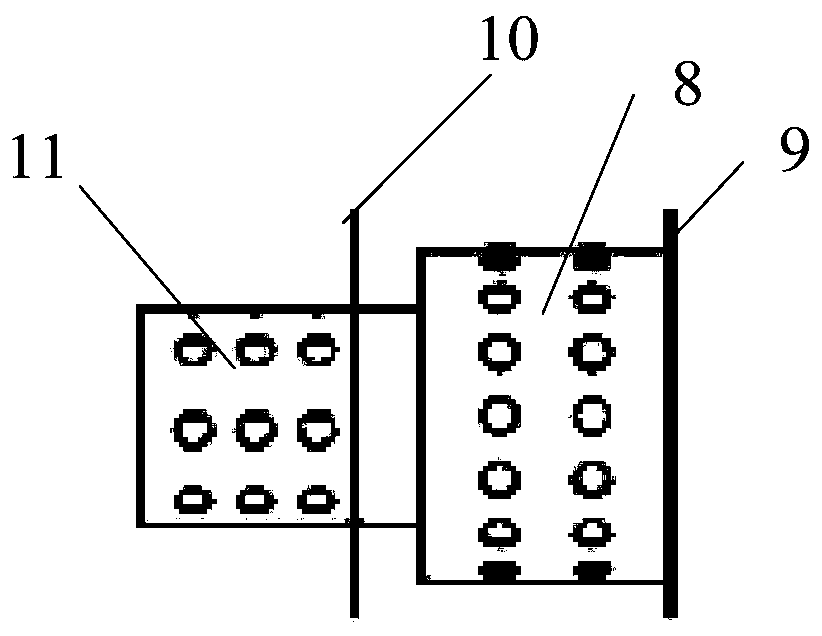

[0096] Example 1: When the number of silencer components is two, these two silencer components are respectively recorded as silencer component 1 and silencer component 2, and the silencer components 1 and 2 are arranged in a row, and the silencer component 1 is the first silencer component , the silencer assembly 2 is the last silencer assembly, the second end of the second resonance chamber 11 of the silencer assembly 1 is in full contact with the closed end of the first expansion chamber 3, and the closed end of the second expansion chamber 8 of the silencer assembly 2 In full contact with the second end of the first resonance chamber 5 .

example 2

[0097] Example 2: When the number of silencer assemblies is three, these three silencer assemblies are respectively recorded as silencer assembly 1, silencer assembly 2, and silencer assembly 3. Noise reduction component 1 is the first noise reduction component, noise reduction component 2 is the middle noise reduction component, and noise reduction component 2 is the last noise reduction component. 2 is the sound-absorbing assembly 3, the second end of the second resonance chamber 11 in the sound-absorbing assembly 2 is in full contact with the closed end of the second expansion chamber 8 of the sound-absorbing assembly 1, and the second expansion chamber 8 of the sound-absorbing assembly 2 The closed end of the sound-absorbing assembly 3 is in full contact with the second end of the second resonance chamber 11, and the second end of the second resonance chamber 11 of the sound-absorbing assembly 1 is in full contact with the closed end of the first expansion chamber 3, and th...

example 3

[0098] Example 3: When the number of silencer components is N, and N is an integer greater than 3, then the N silencer components are respectively recorded as silencer components 1, ..., silencer components i, ..., silencer components N, where i is N -One of the 2 sound-absorbing assemblies, the sound-absorbing assembly 1, ..., the sound-absorbing assembly i..., the sound-absorbing assembly N are arranged in a row, and the sound-absorbing assembly 1 is the first sound-absorbing assembly, and the sound-absorbing assembly i is the first. The middle silencer component, the silencer component N is the last silencer component, then the previous set of silencer components of the silencer component i is the silencer component i-1, and the next silencer component of the silencer component i is the silencer component i+1, then the silencer The second end of the second resonance chamber 11 in component i is in full contact with the closed end of the second expansion chamber 8 of the nois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com