Fuel injection system with self-protection function and pressure control method

A fuel injection system and fuel injector technology, which is applied to fuel injection pumps, fuel injection devices, charging systems, etc., can solve the problems of high pressure control valves, low effective utilization of high pressure fuel, and high material and manufacturing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

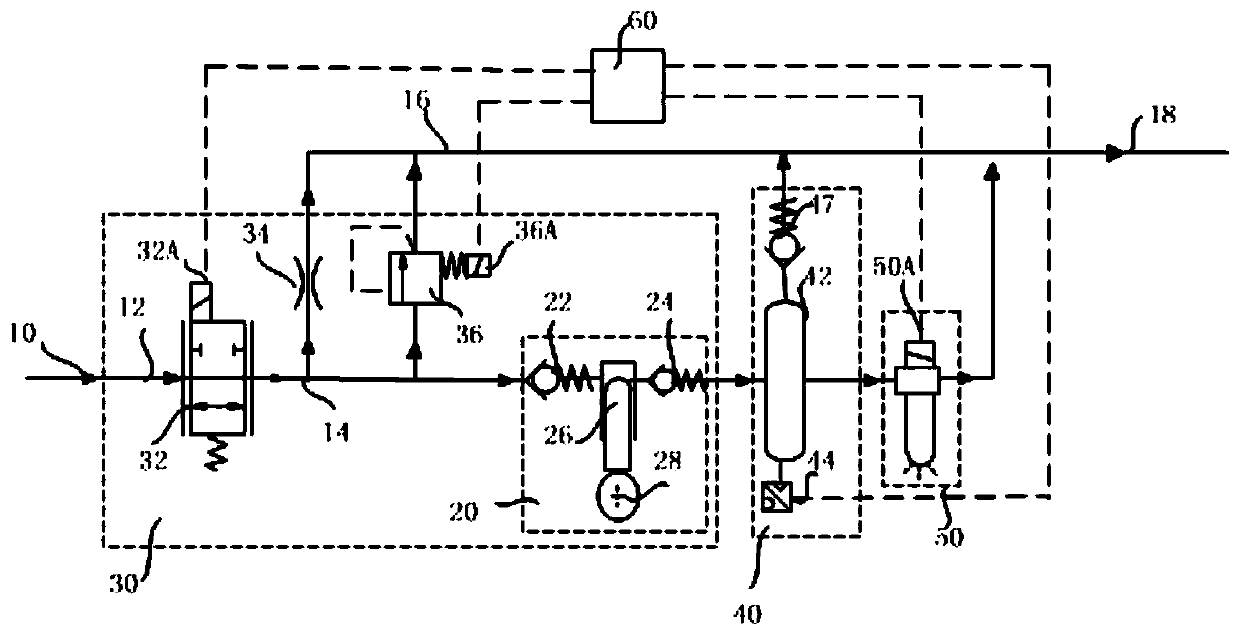

[0038] refer to figure 1 , a fuel injection system with self-protection function, suitable for commercial vehicle power, various construction machinery power, and more suitable for ship power.

[0039] A fuel supply 10 is distributed to the first supply conduit 12 by a low pressure fuel pump, and a flow control valve 32 is provided to meter fuel into the second supply conduit 14 upstream of at least one high pressure fuel pump 20 . An embodiment of the high pressure fuel pump 20 design includes at least an inlet check valve 22 , an outlet check valve 24 , a plunger couple 26 , a drive mechanism 28 and other auxiliary components. The other auxiliary components include the base of the pump body, which is used to arrange various control valves, pipelines, check valves, plug couples, and driving mechanisms. The driving structure 28 is to ensure that the plunger of the plunger pair realizes reciprocating motion as required. The high-pressure common rail assembly 40 stores the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com