Dimming method and device of pipeline detection equipment and computer terminal

A pipeline detection and light adjustment device technology, applied in the direction of electrical components, etc., can solve the problems of high quality, mentality and experience of operators, dazzling feeling, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] For this example, see Figure 4 , shows a schematic flow chart of the pipeline to be inspected according to the embodiment of the present invention. The pipeline to be inspected includes a shaft pipeline and a horizontal pipeline. Such as Figure 4 As shown, at the connection between the vertical pipe and the horizontal pipe, ambient light enters the horizontal pipe through the vertical pipe, and the horizontal pipe is divided into an area that can receive ambient light and an area that cannot receive ambient light.

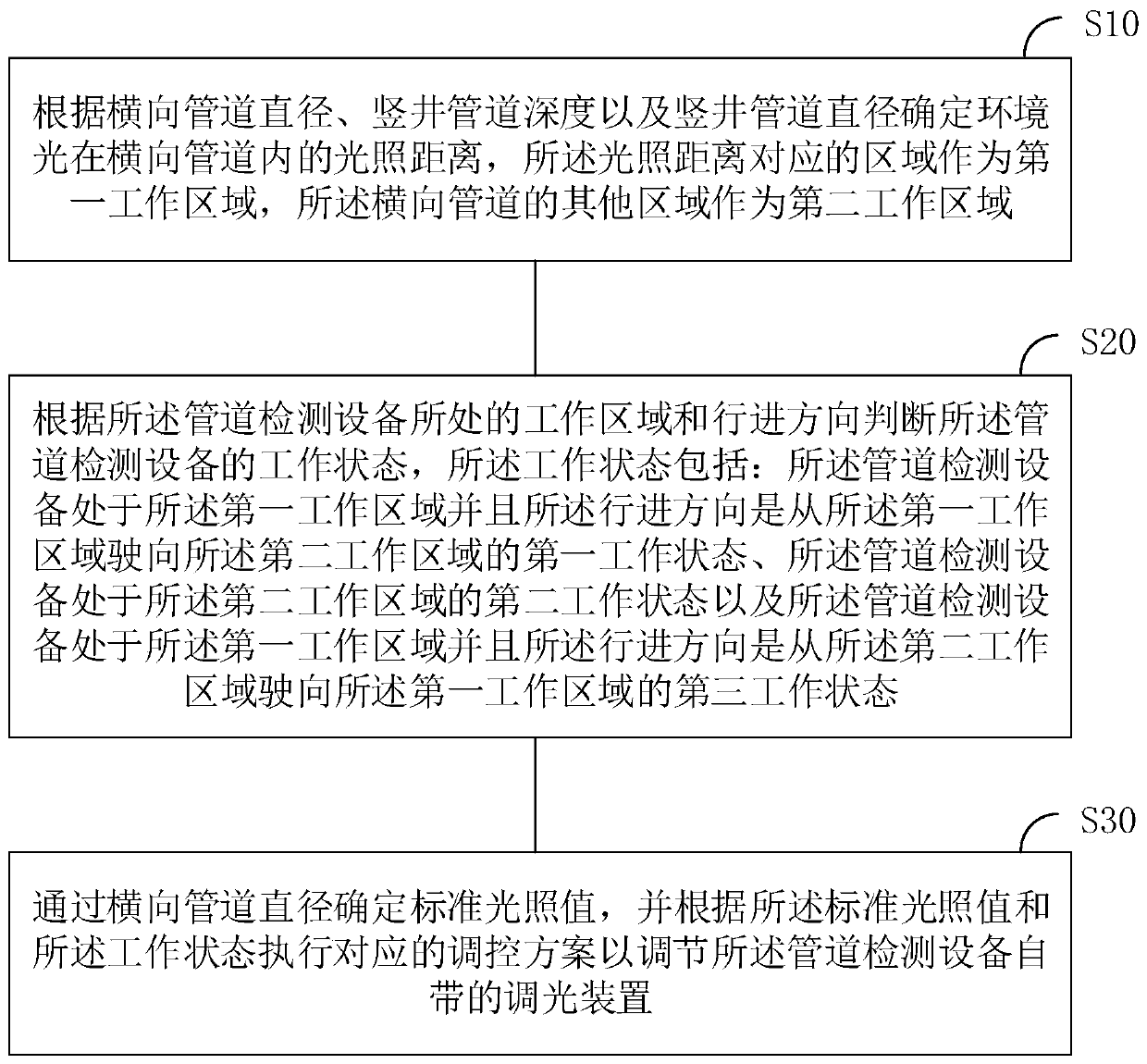

[0051] corresponds to Figure 4 The pipeline structure shown, figure 1 The method of dimming the pipeline inspection equipment is shown to include:

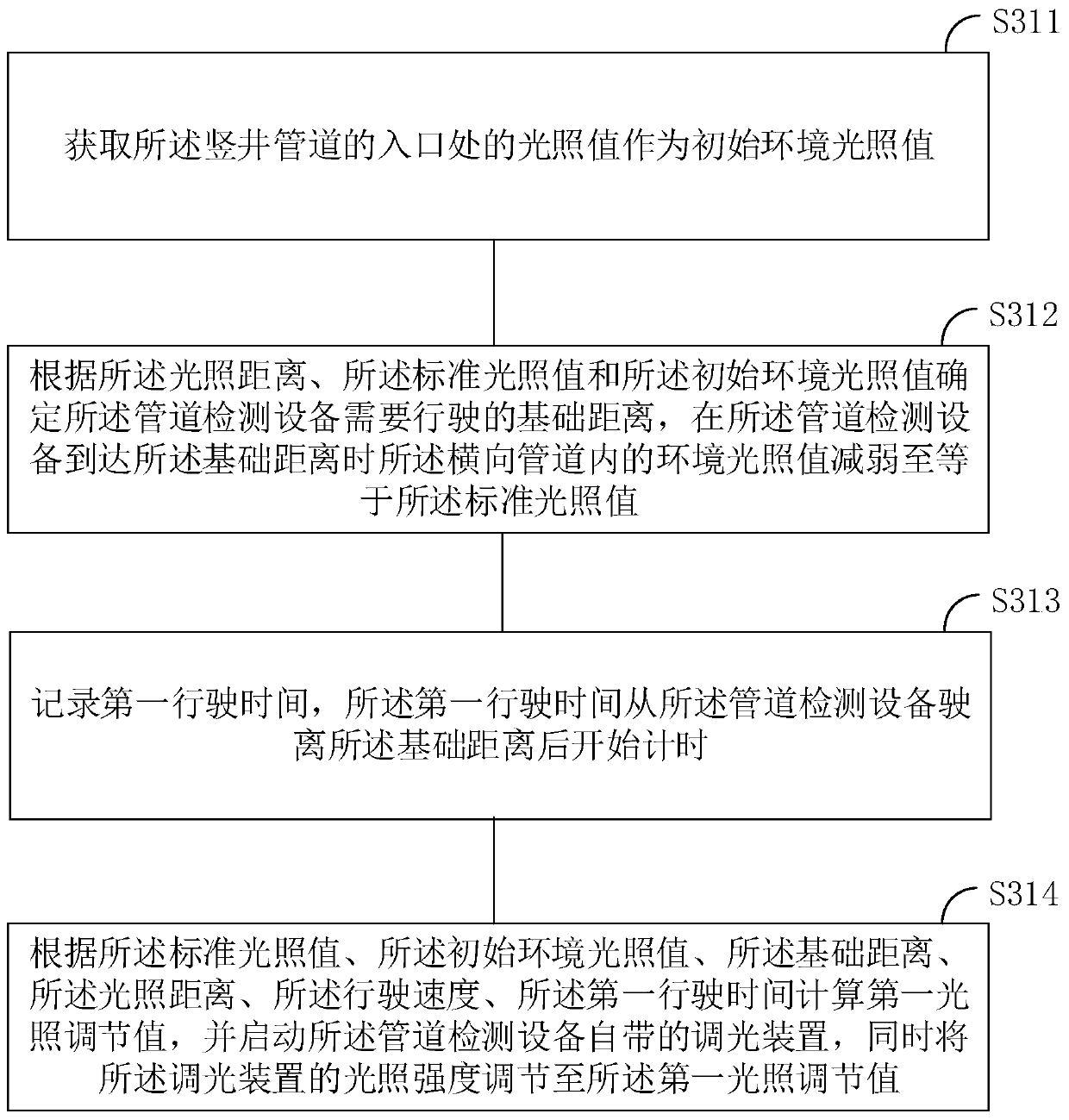

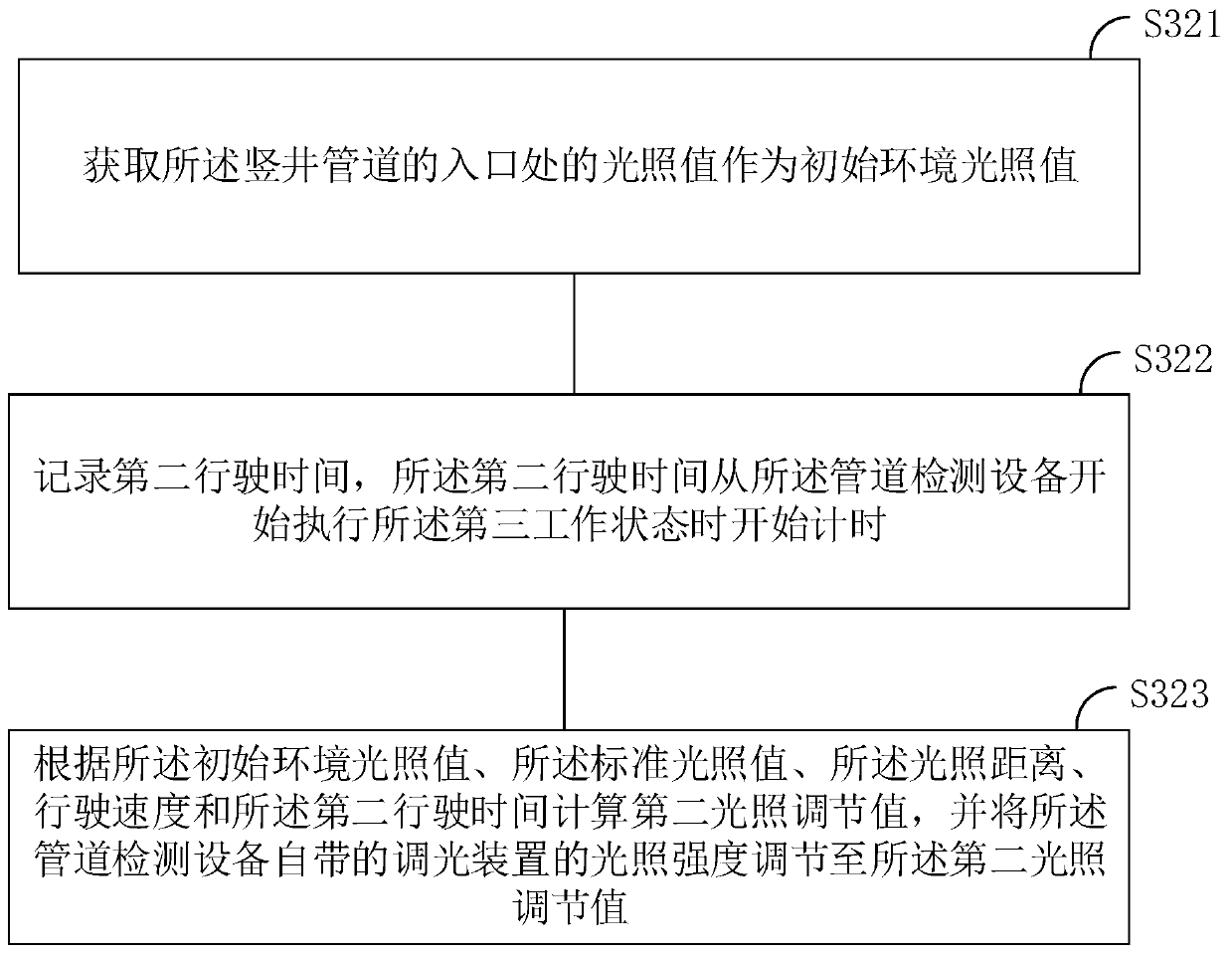

[0052] S10: Determine the illumination distance of the ambient light in the horizontal pipeline according to the diameter of the horizontal pipeline, the depth of the shaft pipeline, and the diameter of the vertical pipeline, the area corresponding to the illumination distance is used as the first working...

Embodiment 2

[0090] In this example, see Figure 5 , showing another schematic structural view of the pipeline to be tested.

[0091] Such as Figure 5 As shown, the pipes to be detected include multiple vertical pipes, and the ambient light is input into the horizontal pipes through the vertical pipes to form a corresponding illumination distance. The pipeline inspection equipment enters the horizontal pipeline through the vertical shaft pipeline, and the above-mentioned vertical shaft pipeline is recorded as the first vertical shaft pipeline, and the illumination distance formed by the first vertical shaft pipeline is recorded as the first illumination distance.

[0092] It can be understood that when the traveling direction of the pipeline detection equipment is away from the entrance of the horizontal pipeline, it will encounter the next vertical shaft pipeline, which is recorded as the second vertical shaft pipeline, and the illumination distance formed by the second vertical shaft p...

Embodiment 3

[0098] In this example, see Image 6 , shows a schematic diagram of the device structure of the pipeline detection equipment.

[0099] Such as Image 6 As shown, the device structure 100 of pipeline detection equipment includes: a working area division module 101 , a working status confirmation module 102 and a device light source control module 103 .

[0100] Wherein, the working area division module 101 is used to determine the illumination distance of the ambient light in the horizontal pipeline according to the diameter of the horizontal pipeline, the depth of the vertical shaft pipeline and the diameter of the vertical pipeline, and the area corresponding to the illumination distance is used as the first working area. Other areas of the transverse duct serve as the second working area.

[0101] A working status confirmation module 102, configured to judge the working status of the pipeline testing device according to the working area and the traveling direction of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com