Acetate fiber filter stick and application thereof

An acetate fiber and filter rod technology, applied in the field of tobacco, can solve problems such as excessive suction resistance of smokers, limit the filtration efficiency of nicotine and glycerin, etc., and achieve the effect of improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

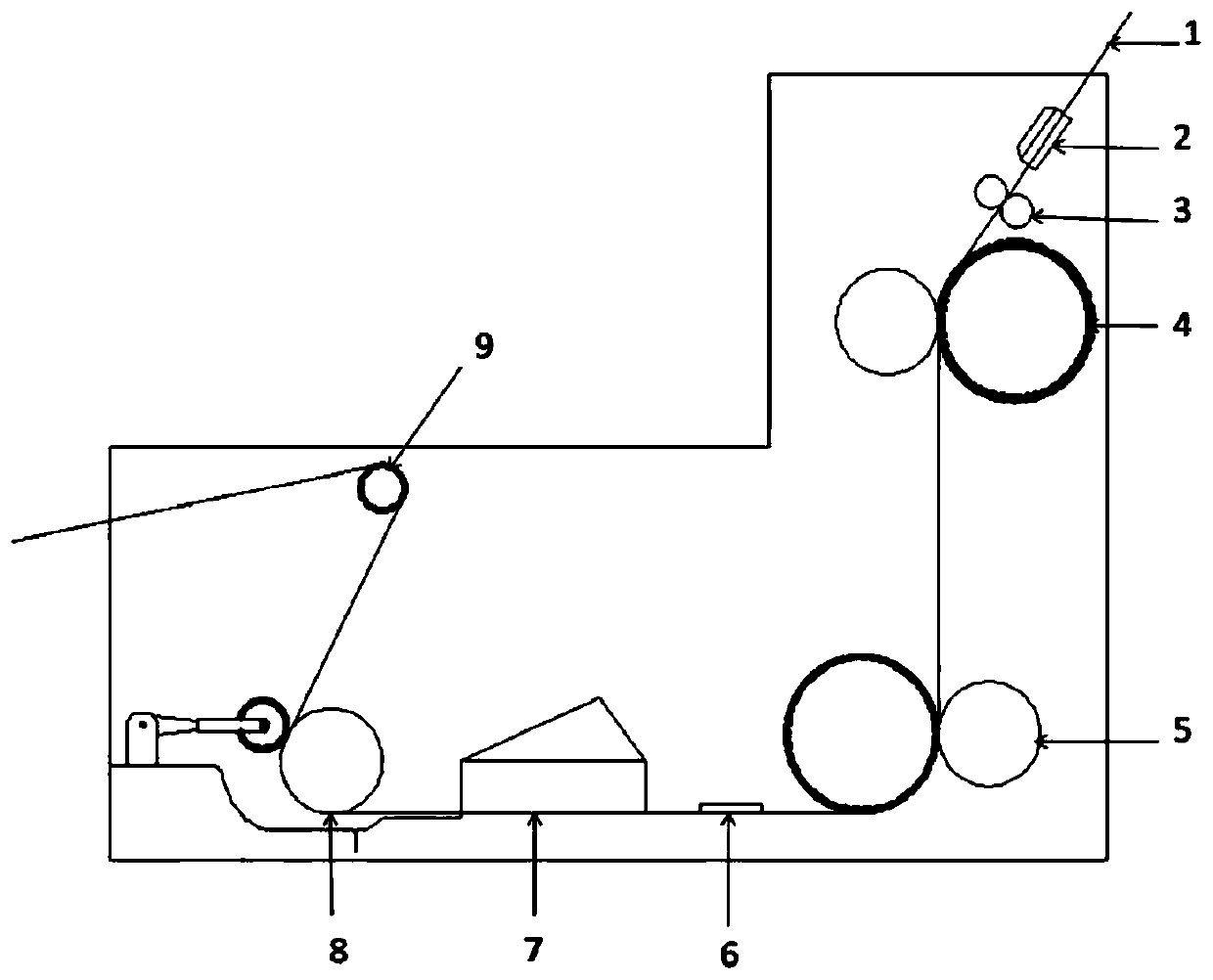

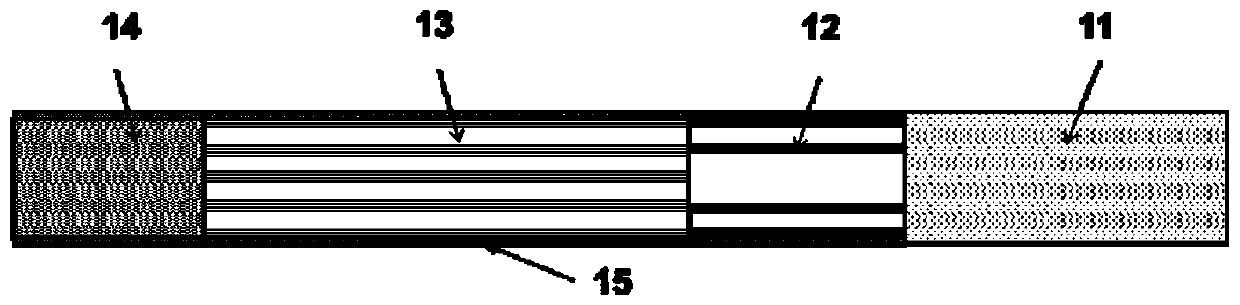

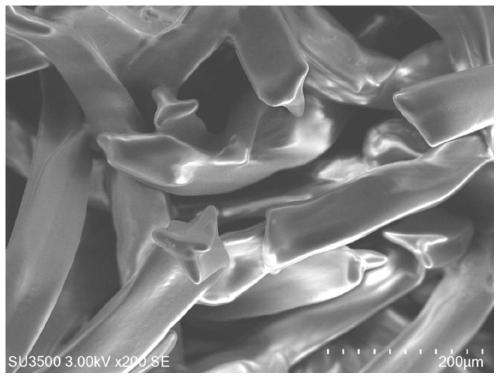

[0028] In this example, diacetate fiber tow with a single denier of 23 denier and a total denier of 28,000 denier is introduced into a KDF4 / AF4 cellulose acetate filter rod forming machine, and 9.6% triacetin is applied to make a cellulose acetate filter rod . Such as figure 1 As shown, diacetate fiber tow 1 is fed from the feed inlet not shown in the figure, and then passes through the air-assisted opener 2, the pretension roller group 3, the feed roller group 4, the opening roller group 5 and the opener 15 enters the plasticizer spraying chamber 6, sprays 9.6% glycerol triacetate in the plasticizer spraying chamber 6, then continues to pass through the conveying roller group 8 and the wedge roller group 9, and is finally transported to the molding machine not shown in the figure , and made into cellulose acetate filter rods.

[0029] Processing circle 21.80-24.40mm cellulose acetate filter rod, the length of the filter rod is 132mm, no corrosion on the surface of cellulos...

Embodiment 2

[0031] Compared with Embodiment 1, this embodiment also adopts diacetate fiber tow with 23 deniers and a total denier of 28000 deniers in the present invention. The difference is that 15.8% triacetin is applied to make acetate fibers For the filter rod, no corrosion phenomenon was found on the surface of the cellulose acetate in the experiment, and other indicators remained unchanged.

Embodiment 3

[0033] Compared with Embodiment 1, this embodiment also adopts diacetate fiber tow with 23 deniers and a total denier of 28000 deniers in the present invention. The difference is that 28.7% glyceryl triacetate is applied to make acetate fibers For the filter rod, no corrosion phenomenon was found on the surface of the cellulose acetate in the experiment, and other indicators remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com