Composite electret fiber filter

A technology of fiber filter and electret, which is applied in the direction of gravity filter, loose filter material filter, filter separation, etc., can solve the problems of difficult replacement, affecting filtration efficiency, large water head loss, etc., and achieves convenient inspection and replacement, Multiple adjustment methods and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

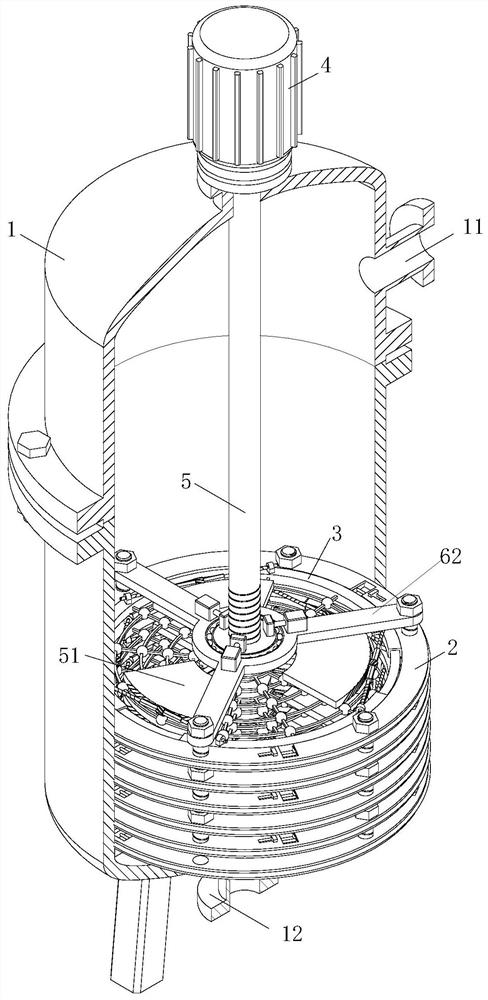

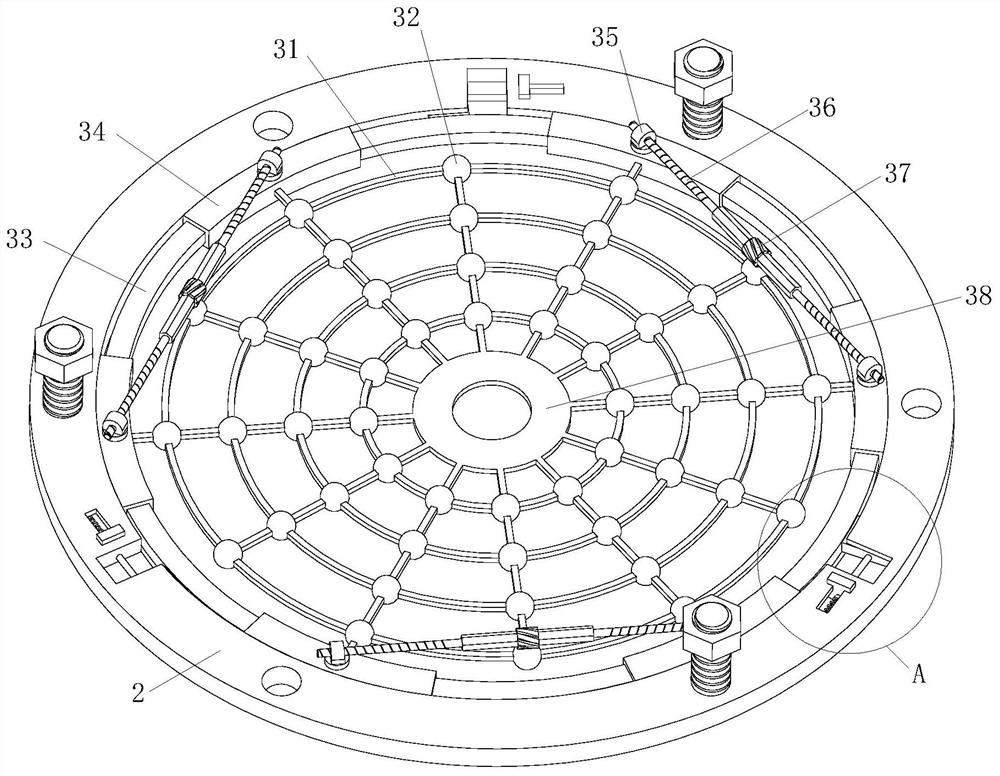

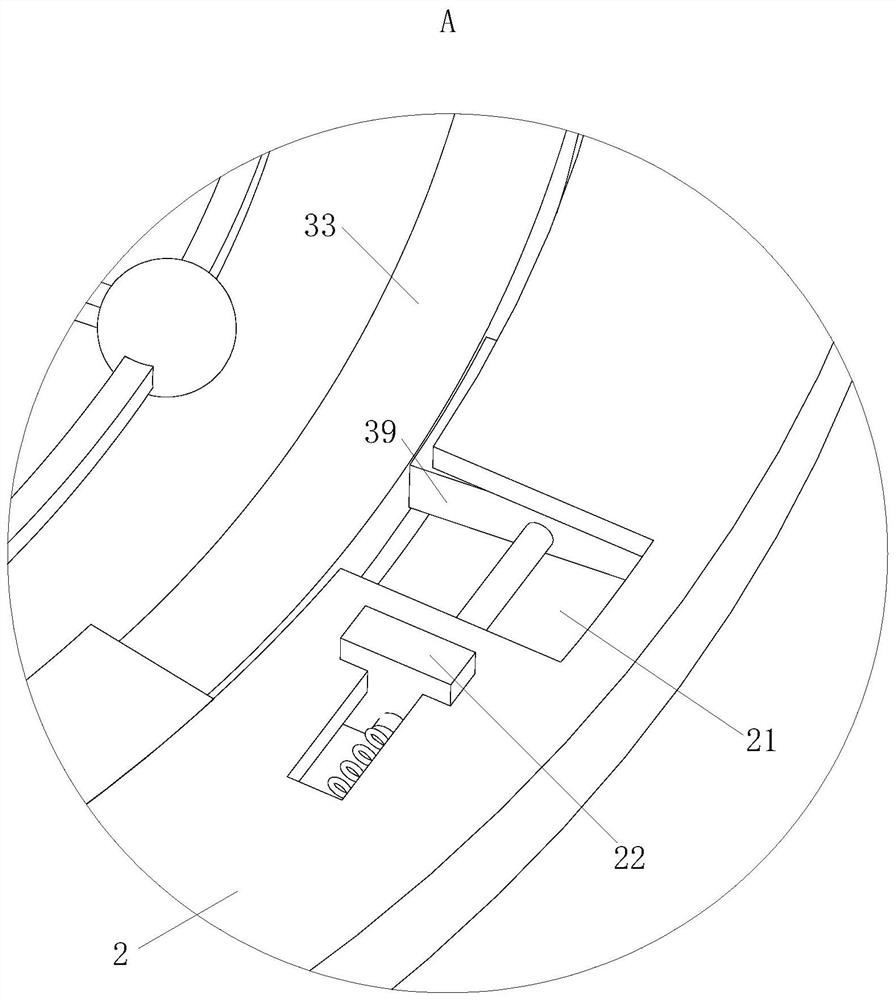

[0028] As an embodiment of the present invention, the axial adjustment fixing frames 2 inside the tank body 1 are arranged in layers, and the axial adjustment fixing frames 2 are connected by bolts and nuts; the shaft 5 is threadedly connected with an axial adjustment module 6 , the axial adjustment module 6 is fixedly installed on the bolt upper end of the axial adjustment fixing frame 2; when working, the axial adjustment fixing frame 2 of each layer is connected by bolts and nuts, and the gap is limited at the same time, so that the axial adjustment and fixing of each layer The frame 2 can be slidably adjusted on the bolt, so that the vertical gap of the filter fiber ball 32 can be adjusted, and the adjustment range of the filter fiber ball 32 gap in different horizontal planes can be determined according to the difference of water quality; the rotating shaft 5 is driven by the motor 4 to rotate, and the rotating shaft 5 further drives the axial adjustment module 6 to move u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com