A kind of method for preparing rhenium metal

A technology of metal and rhenium powder, which is applied in the field of preparing metal rhenium, can solve problems such as increased process costs, achieve the effects of increasing specific surface area and surface energy, uniform particle shape, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Raw material: high-purity ammonium perrhenate, purity 99.96%;

[0044] Implementation process:

[0045] The first step is to prepare high-purity ultrafine ammonium perrhenate;

[0046] 1) Add the raw materials into pure water at 60°C at a solid-to-liquid ratio of 140g:1L, stir until completely dissolved, adjust the pH to 8~9 with ammonia water, and slowly add H at a ratio of 0.5mL / g 2 o 2 , stop heating and filtering until there are no bubbles, and cool the filtrate to room temperature;

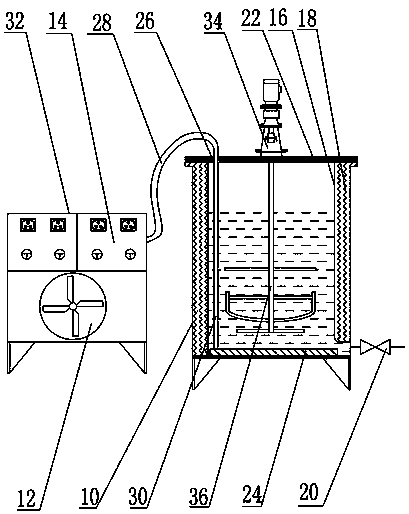

[0047] 2) Introduce the filtrate into the ultrasonic crystallizer, conduct ultrasonic crystallization at 2°C for 1 hour, and the ultrasonic power of the ultrasonic crystallizer is 1000W; Ultrasonic vibrating plate, the ultrasonic vibrating plate is set at the bottom of the kettle body and fixed on the mounting hole of the thermal insulation plate through the fixing rod, and can be disassembled freely;

[0048] 3) After the crystallization is completed, drain, dehydrate, and vacuum ...

Embodiment 2

[0053] Raw material: crude ammonium perrhenate, purity 99.50%;

[0054] Implementation process:

[0055] The first step is to prepare high-purity ultrafine ammonium perrhenate;

[0056] Add the raw materials into pure water at 80°C at a solid-to-liquid ratio of 160g:1L, stir until completely dissolved, adjust the pH to 8~9 with ammonia water, and slowly add H at a ratio of 2mL / g. 2 o 2 , stop heating and filtering until there are no bubbles, and cool the filtrate to room temperature;

[0057] 2) Introduce the filtrate into the ultrasonic crystallizer, conduct ultrasonic crystallization at 0~1°C for 3 hours, and the ultrasonic power of the ultrasonic crystallizer is 2000W; The device uses 5 ultrasonic vibrating rods, and the top of each ultrasonic vibrating rod is fixed on the corresponding 5 mounting holes on the thermal insulation board through connecting rods, and can be disassembled freely;

[0058] 3) After the crystallization is completed, drain, dehydrate, and vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com