Three-stage dust removal and desulphurization device

A desulfurizer and program technology, applied in the field of three-program dust removal desulfurizer, can solve the problems of large floor space, low desulfurization efficiency, large water consumption, etc., and achieve the effects of less power consumption, less water consumption, and low use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

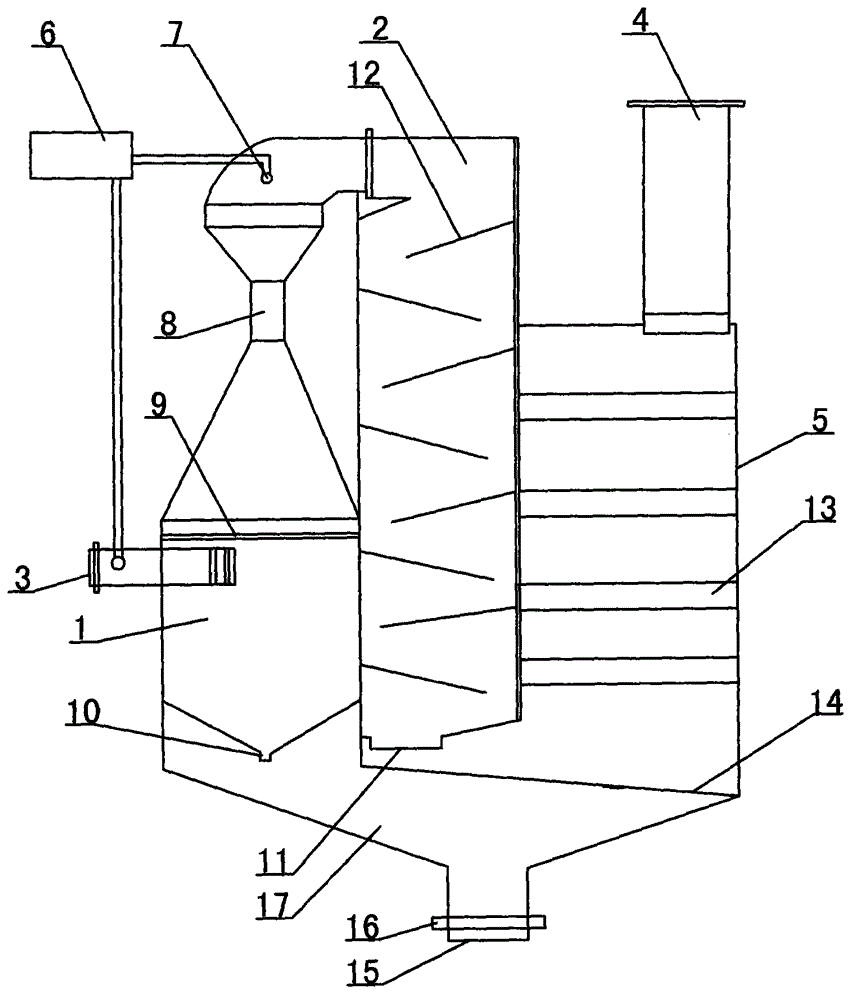

[0014] Such as figure 1 As shown, the three-stage dust removal and desulfurizer described in the embodiment of the present invention includes a cyclone cylinder 1, a flow deflector 2 and a filter 5, the top port of the cyclone cylinder 1 is connected to the flow deflector 2, and the cyclone cylinder 1. The upper part is funnel-shaped and is provided with a Venturi throat 8. The bottom of the swirl tube 1 is provided with a settling tank 10 and communicates with the sewage chamber 17 below; An atomizing nozzle 7 is arranged on the inside of the tuyere 3 and in the air duct above the Venturi throat 8, and the two atomizing nozzles 7 are connected to the dosing box 6 outside the cyclone 1; the cyclone 1 above the air inlet 3 A speed brake 9 is horizontally laid in the interior. The interior of the deflector 2 is arranged in a staggered manner from top to bottom with a number of obliquely arranged deflectors 12 and together form several layers of stepped structures in the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com