Ballast water filtering device with backwashing and electric brush cooperative self-cleaning function

A filter device and electric brush technology, applied in the direction of filtration and separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of manpower consumption, easy to block the filter screen, affect seawater ballast efficiency, etc., and achieve a high degree of automation , no special management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

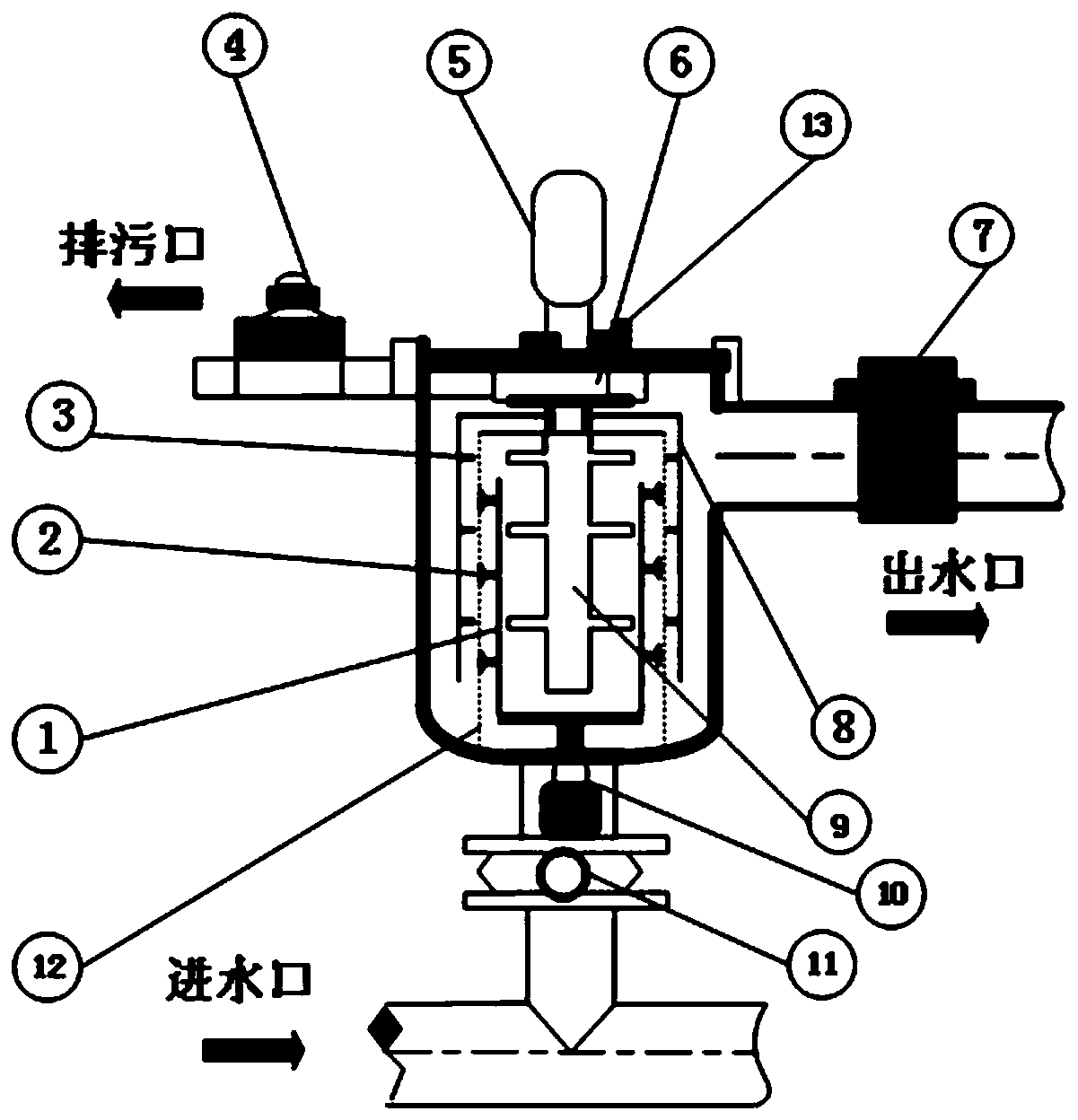

[0034] Such as Figure 1-5 As shown, the present invention provides a ballast water filtration device including backwash and electric brush cooperative self-cleaning function, which device includes:

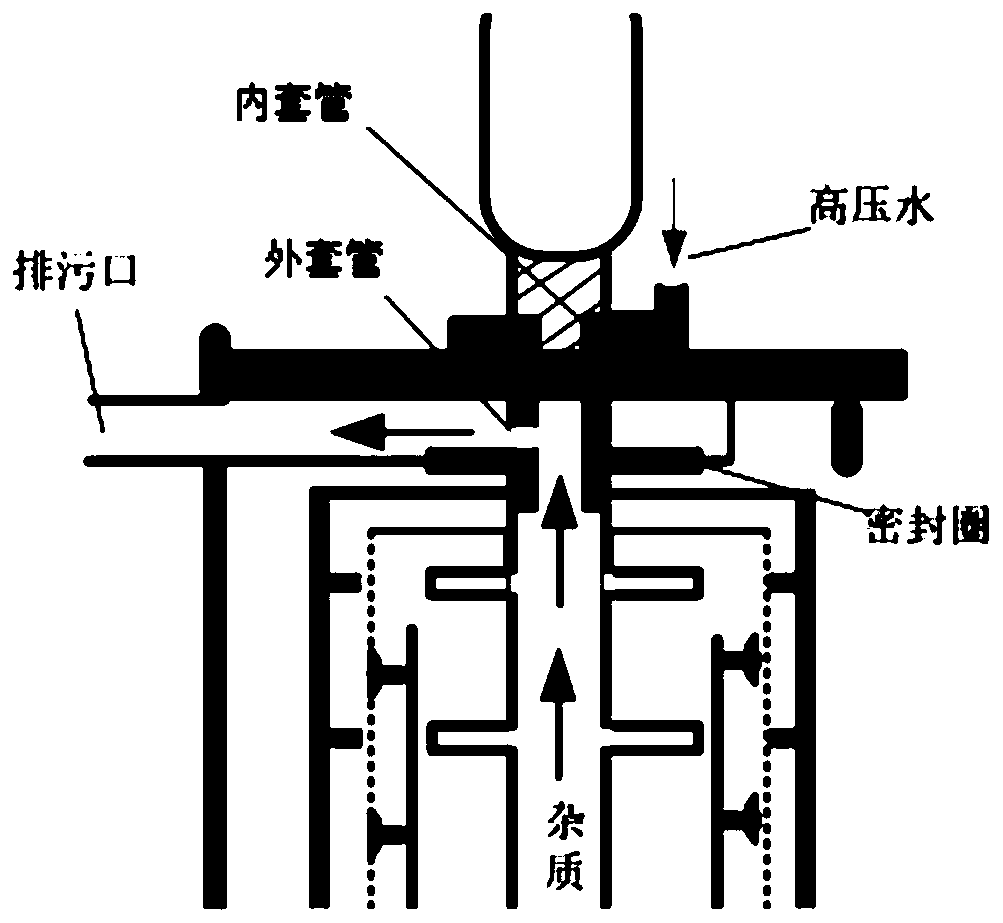

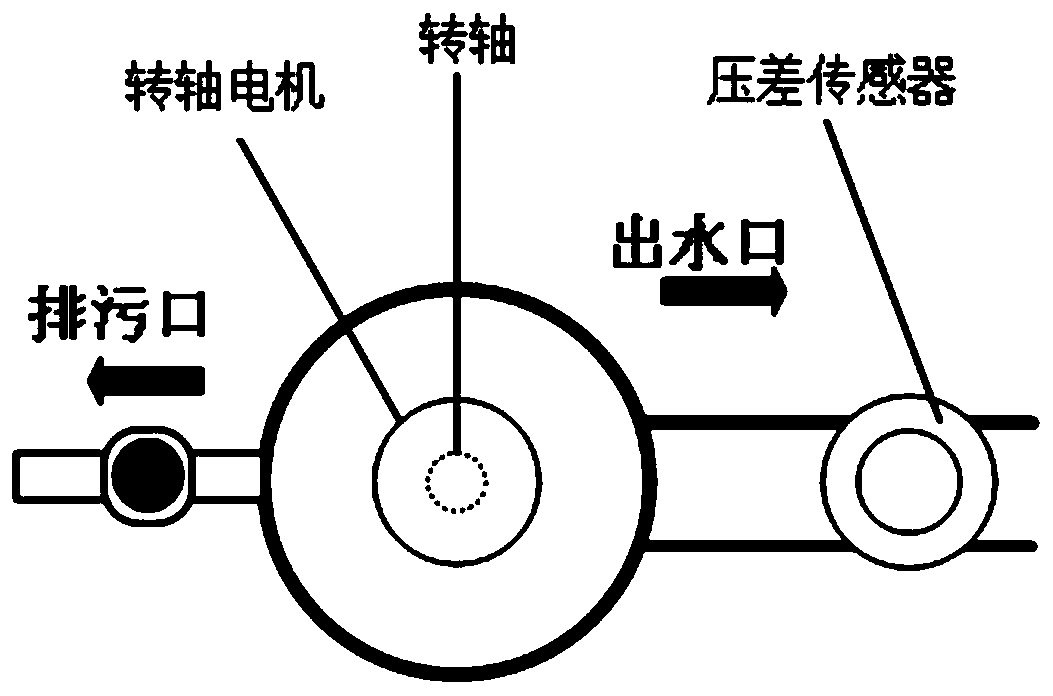

[0035] A vertical filter cartridge, an inverted cylindrical filter screen 12 is installed at the bottom of the filter cartridge, and a water inlet is arranged at the bottom of the filter cartridge, and seawater passes through the filter screen 12 and flows to the water outlet. The upper end of the filter cartridge is equipped with a sealed ring-shaped cover, which is detachably connected to the wall of the filter cartridge. There is a hollow double-layer sleeve-shaped rotating shaft in the center of the cover, and the rotating shaft is driven by the rotating shaft motor 5 on the cover. The outer side of the filter screen 12 is provided with a high-pressure nozzle 3 in the direction opposite to the sewage outlet. After the filtered seawater is pressurized by a high-pressure water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com