Multi-class solid waste mixing and drying system

A solid waste, multi-category technology, applied in the field of multi-category solid waste mixed drying system, can solve the problems of low efficiency and long biological drying cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions and technical effects of the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

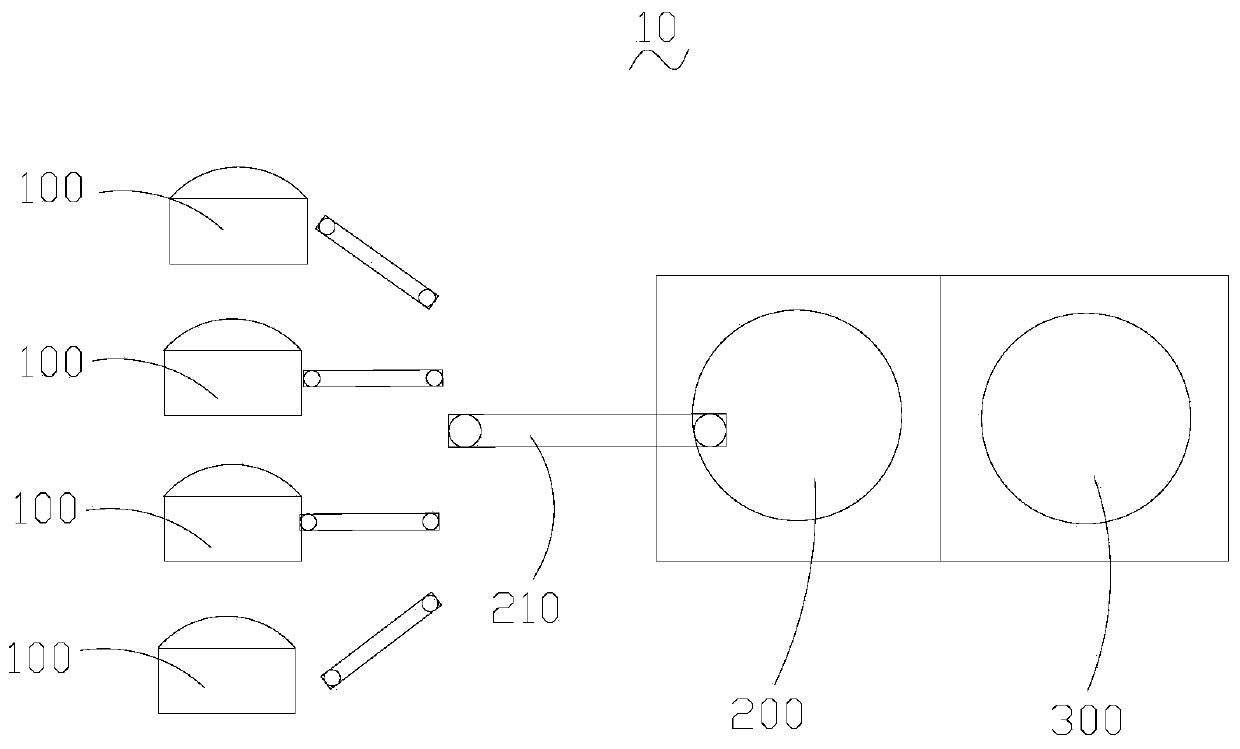

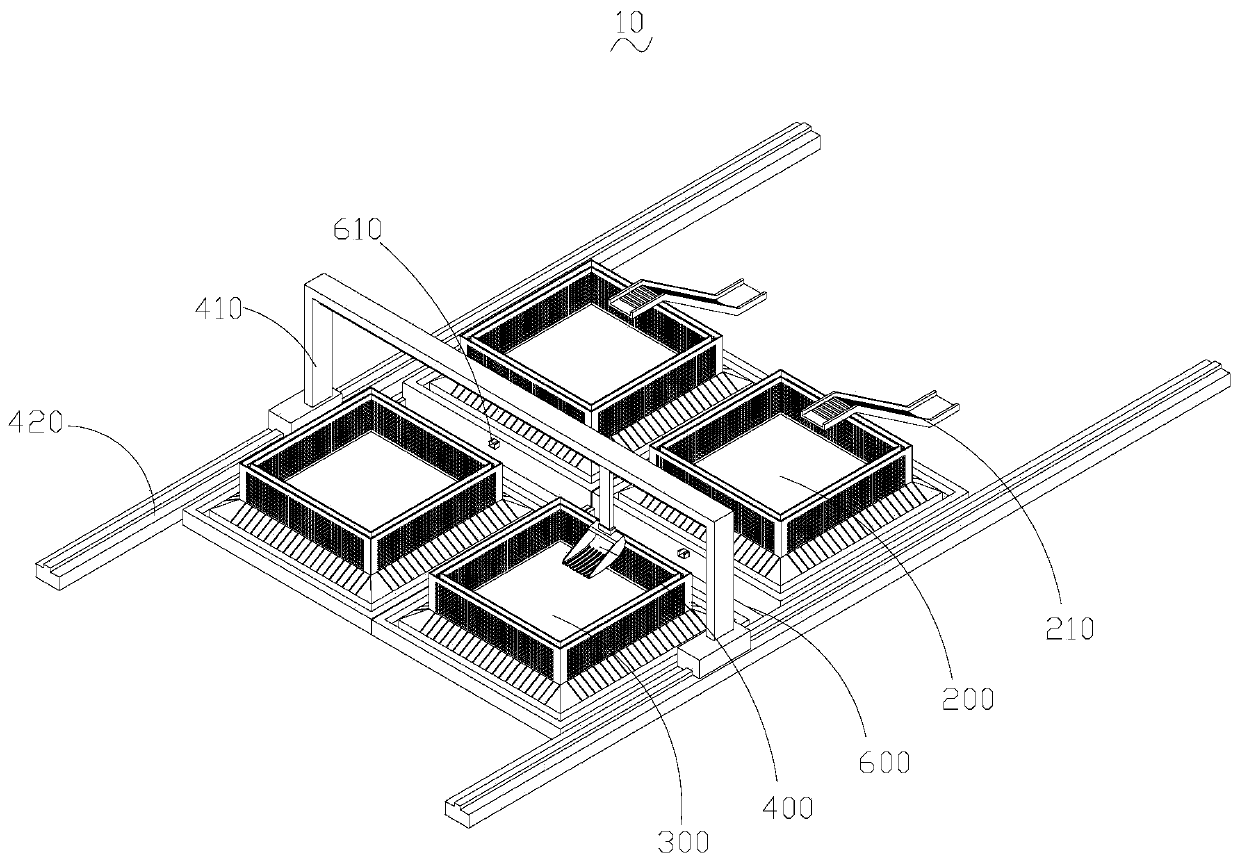

[0028] Please see figure 1 and figure 2 , in a specific embodiment, a multi-category solid waste mixing and drying system 10 includes: several solid waste temporary storage bins 100 for separately storing different types of solid waste, layered fermentation stacking tanks 200, mixing Biological drying tank 300, transfer grab 400.

[0029] The layered fermentation stacking pool 200 is respectively connected to each of the solid waste temporary storage bins 100 through a solid waste conveying device 210 , and the mixed biological drying pool 300 is set close to the layered fermentation stacking pool 200 . The transfer grab 400 is set above the layered fermentation stacking tank 200 and can move to the top of the mixed biological drying tank 300 .

[0030] For example, the transfer gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com