Hemming head assembly with pressure detection

A pressure and hemming technology, applied in vehicle parts, manufacturing tools, transportation and packaging, etc., can solve the problem of inability to detect the tension value of the hemming head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

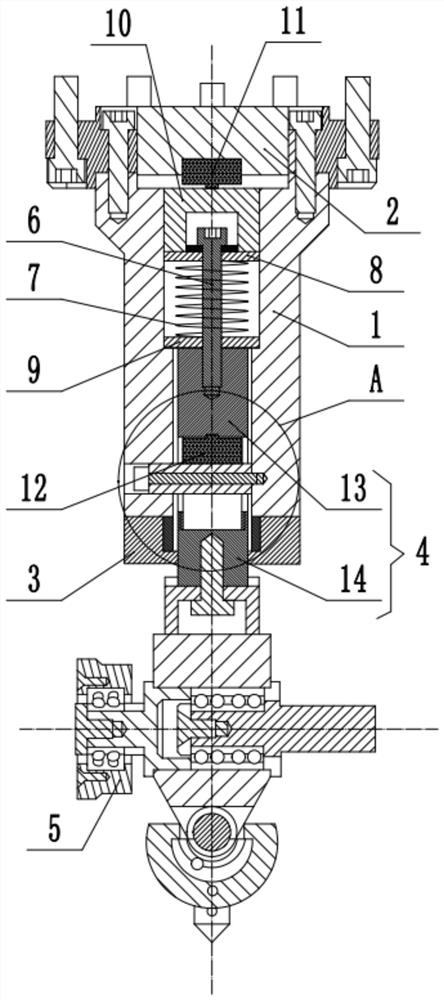

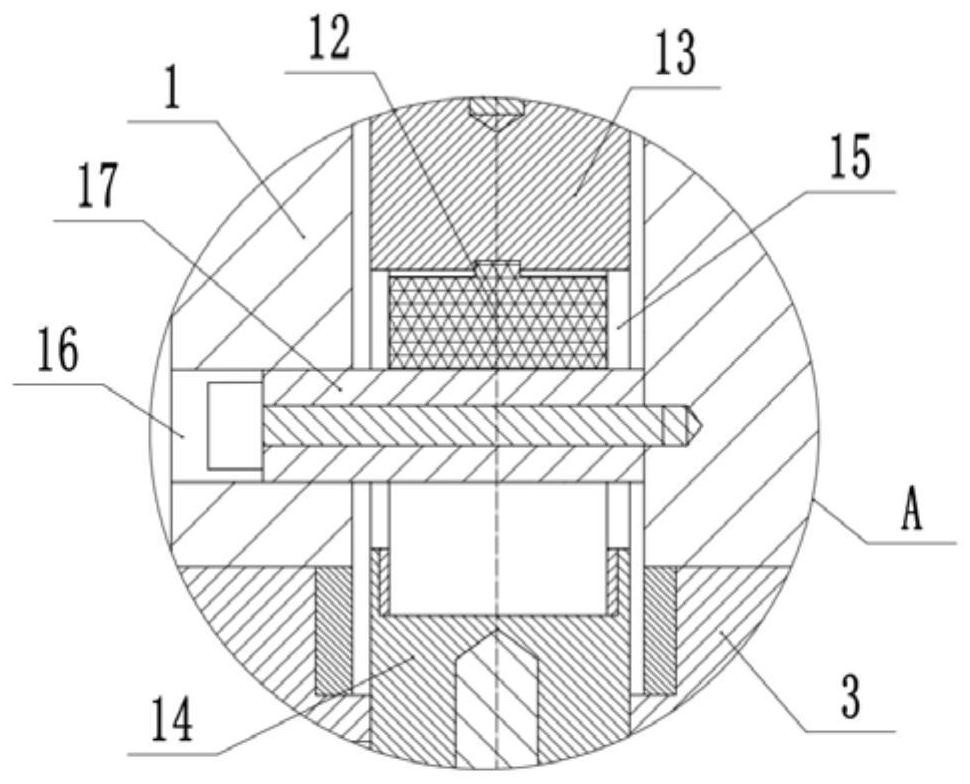

[0032] Embodiment one is basically as figure 1 As shown, the hemming head assembly with pressure detection includes a cylindrical support 1. The support 1 has a through hole along its axial direction. The upper end of the support 1 is fixedly connected with the upper end cover 2 by screws. The lower end of the seat The lower end cover 3 is fixedly connected by screws, the lower end cover 3 is provided with a vertical via hole, and the main shaft 4 is vertically slidably connected in the seat, and the lower end of the main shaft 4 passes through the via hole of the lower end cover 3 and is connected with a piping for hemming The upper end of the head 5 and the main shaft 4 is fixedly connected with a long screw 6 through a threaded fit, the long screw 6 is covered with a spring 7, the top of the spring 7 is welded with an upper baffle 8, and the lower end of the spring 7 is welded with a lower baffle 9, A gasket is provided between the bottom surface of the head of the long scr...

Embodiment 2

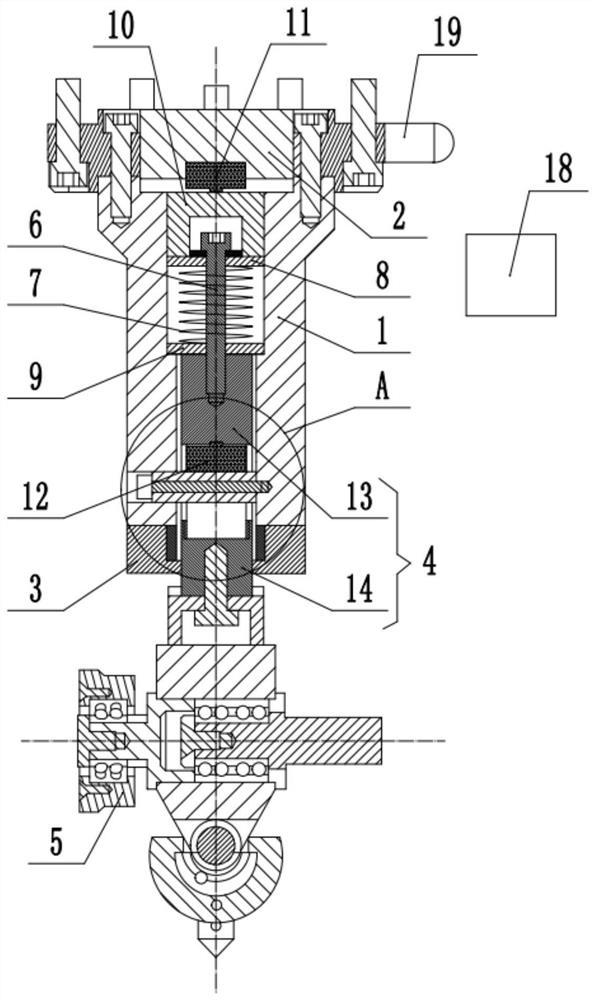

[0040] The difference between embodiment two and embodiment one is: as image 3 As shown, the controller 18 is connected on the pressure display. In the present embodiment, the controller 18 adopts a model of STM32 single-chip microcomputer, and the signal input end of the controller 18 is electrically connected with the signal input end of the pressure display. At the same time, the output of the controller 18 The terminal is electrically connected to the alarm device 19. By setting the reasonable range value of the rolling force on the controller 18, the controller 18 can calculate and analyze the pressure signal value output by the pressure display. When the pressure is within the range, the controller 18 controls the alarm 19 to energize and alarm, thereby alerting the hemming operator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com