Pushing installation method for high-pier large-span support-free steel box girder in mountainous area

An installation method and technology of steel box girders, which are applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as consuming a lot of man-hours, affecting safe construction, and instability of supports, so as to reduce material input, improve construction efficiency, The effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

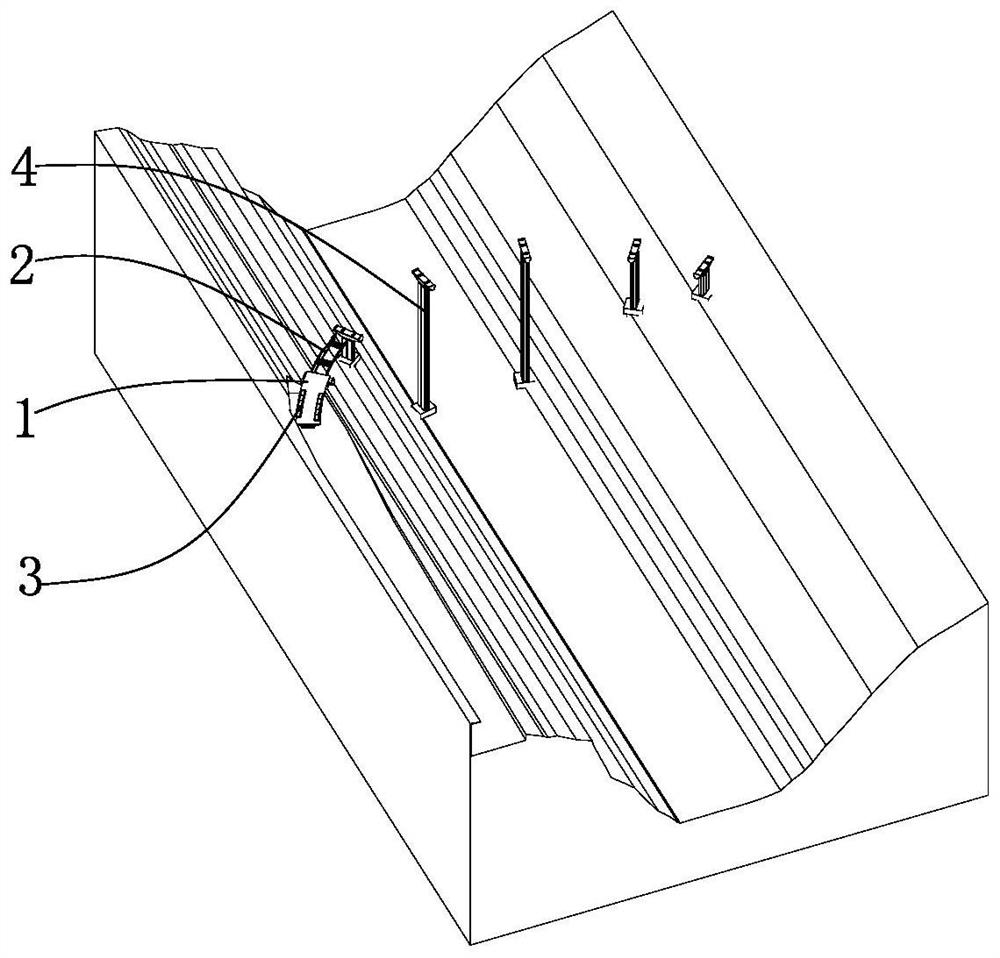

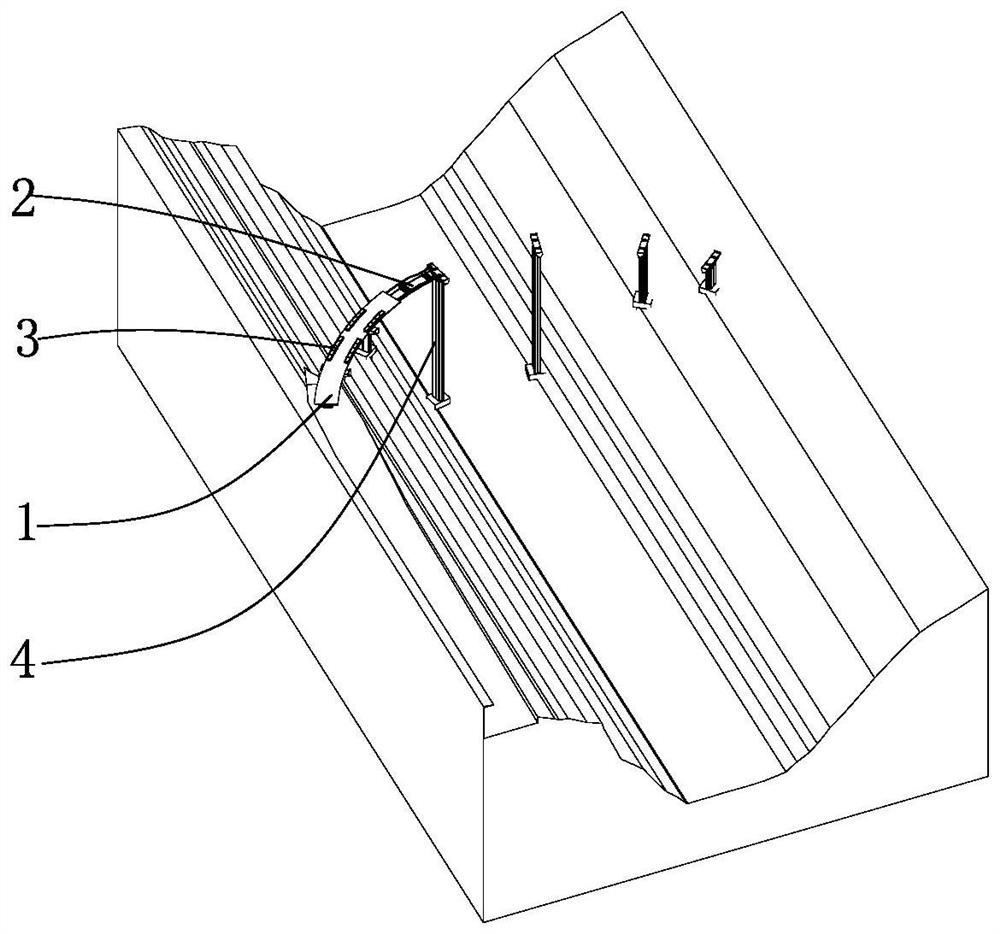

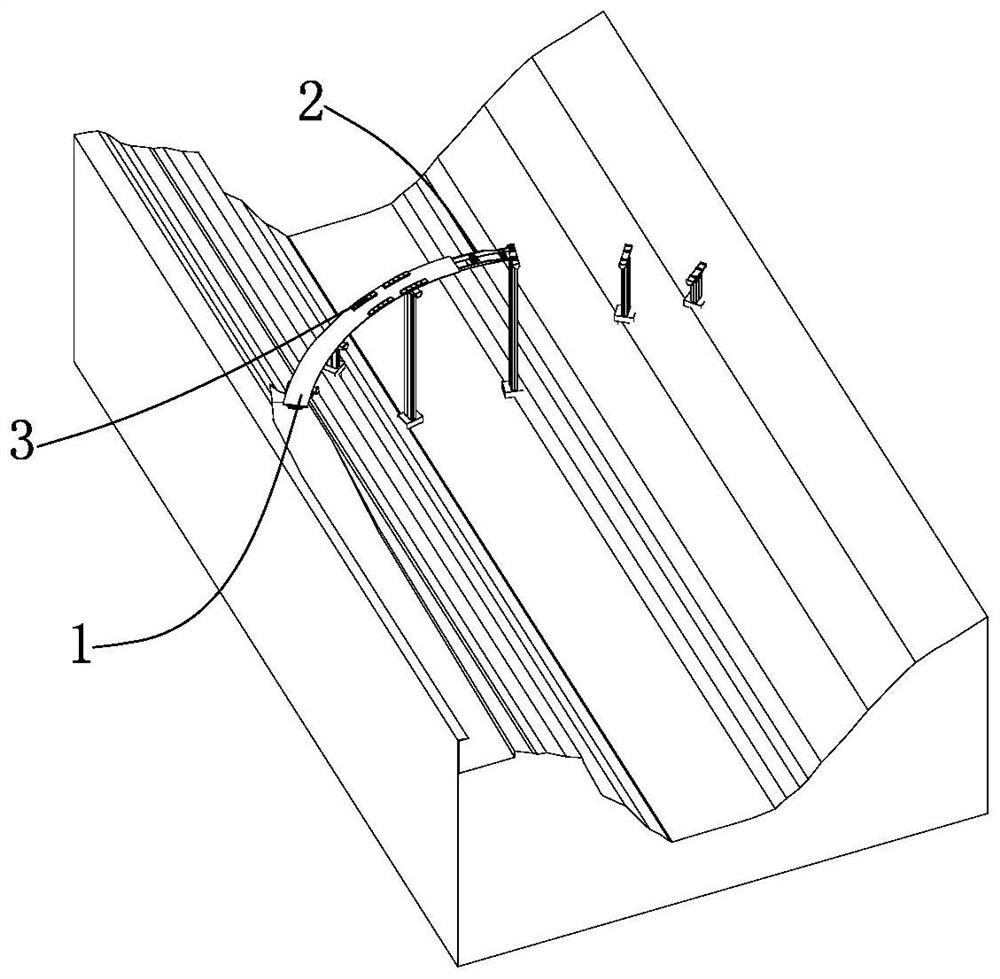

[0016] (1) such as figure 1 As shown in the bridge head assembled the steel box beam; the first steel box beam 1 assembled, the guideline 2 is mounted on the front end of the steel box beam, and a row tank 3 is provided along the longitudinal direction of the top surface of the steel box beam, each column of water A plurality of separate tanks, each water tank with separate water pipes and effluent pipe water tanks and pumping water from the water tank; no water in the water tank.

[0017] (2) In the first steel box girder 1 and each permanent bridge pier 4 is set on the step jack, start the steel box beam push; when the guidewell and the steel box beam form a cantilever, monitor the cantilever at any time, and the flexibility is reached When the maximum allowable value is injected within the water tank 3 located behind the cantilever, the cantilever is flexible by the water tank counter, ensuring that the flexible amount of the cantilever does not exceed the maximum allowable val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com