On-line detection method and system for resistance spot welding spatter based on intrinsic process signal

A process signal and resistance spot welding technology, applied in resistance welding equipment, welding equipment, welding power supply, etc., can solve the problems affecting the surface quality and positioning accuracy of the car body, affecting the mechanical properties of spot welding joints, and unable to detect on-line in real time, etc., to achieve The effects of fast calculation speed, good linear correlation, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

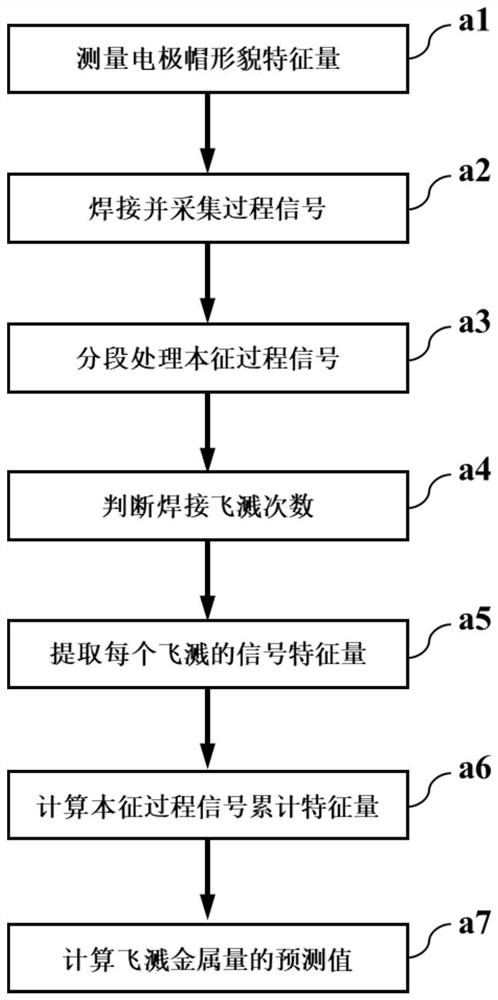

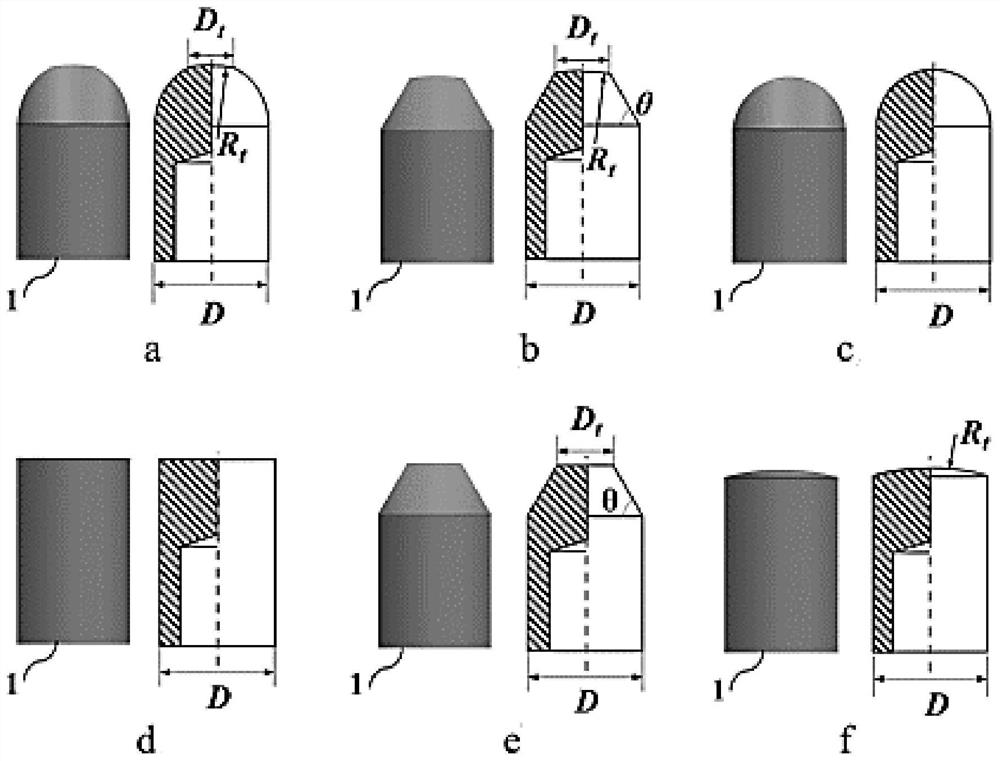

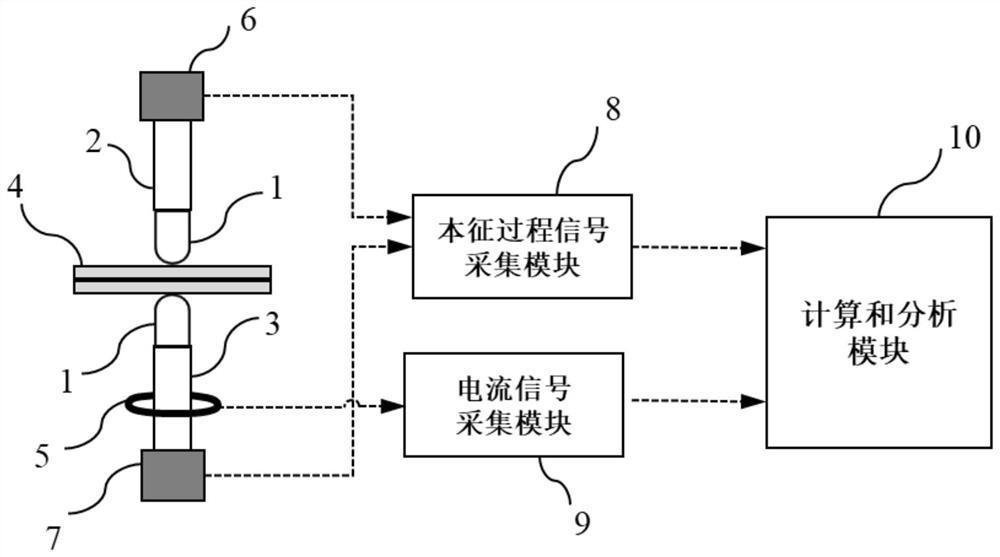

[0027] Such as figure 1 As shown, this embodiment relates to an on-line detection method for resistance spot welding spatter based on intrinsic process signals, which obtains the shape feature quantity of the electrode cap 1 by measuring, then performs welding and collects welding current and intrinsic process signals, and establishes the energization The relationship diagram of the intrinsic process signal changing with time in the welding stage, the relationship diagram is combined with the spatter criterion to judge the number of spatters, the characteristic quantity of each spatter is extracted and combined to obtain the cumulative characteristic quantity of the intrinsic process signal in the spattering process, through this The volume of the splashed metal is calculated by accumulating the characteristic quantity and the shape characteristic quantity of the electrode cap 1, and then the predicted value of the quantity of the splashed metal is obtained.

[0028] Such as ...

Embodiment 2

[0047] Such as figure 2 As shown in b, compared with the embodiment 1, the electrode cap 1 of the present embodiment is an arc-surface cone-top electrode, and the dynamic electrode pressure signal is preferably used as the intrinsic process signal, and the intrinsic process signal sensor 6 of the upper electrode is a load cell. The lower electrode intrinsic process signal sensor 7 is a surface strain sensor, the current sensor 5 is a Hall current sensor 5, and the calculation and analysis module 10 is a monitor.

[0048] Such as Figure 8 As shown, in this embodiment, the threshold A is set to 30N, and the start time and end time of splashing are judged according to the intersection of the dynamic electrode pressure differential signal and the threshold horizontal line, and the number of splashes is determined as one, and the splashing is marked as F 1 , the obtained cumulative feature quantity calculates the volume of spattered metal in the welding process Among them: K ...

Embodiment 3

[0051] Such as figure 2 As shown in c, compared with Example 1, the electrode cap 1 of this embodiment is a spherical electrode, and the bottom diameter D of the electrode cap 1 needs to be measured, and the expression for the volume of the splashed metal is: Among them: K 3 is the correction factor chosen according to the different intrinsic process signals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com