Hole automatic alignment device for numerical control machining center

A technology of machining centers and mobile devices, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of inaccurate manual operation, affecting processing efficiency, and long time required for alignment, achieving convenient disassembly, The effect of increasing processing efficiency and saving alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

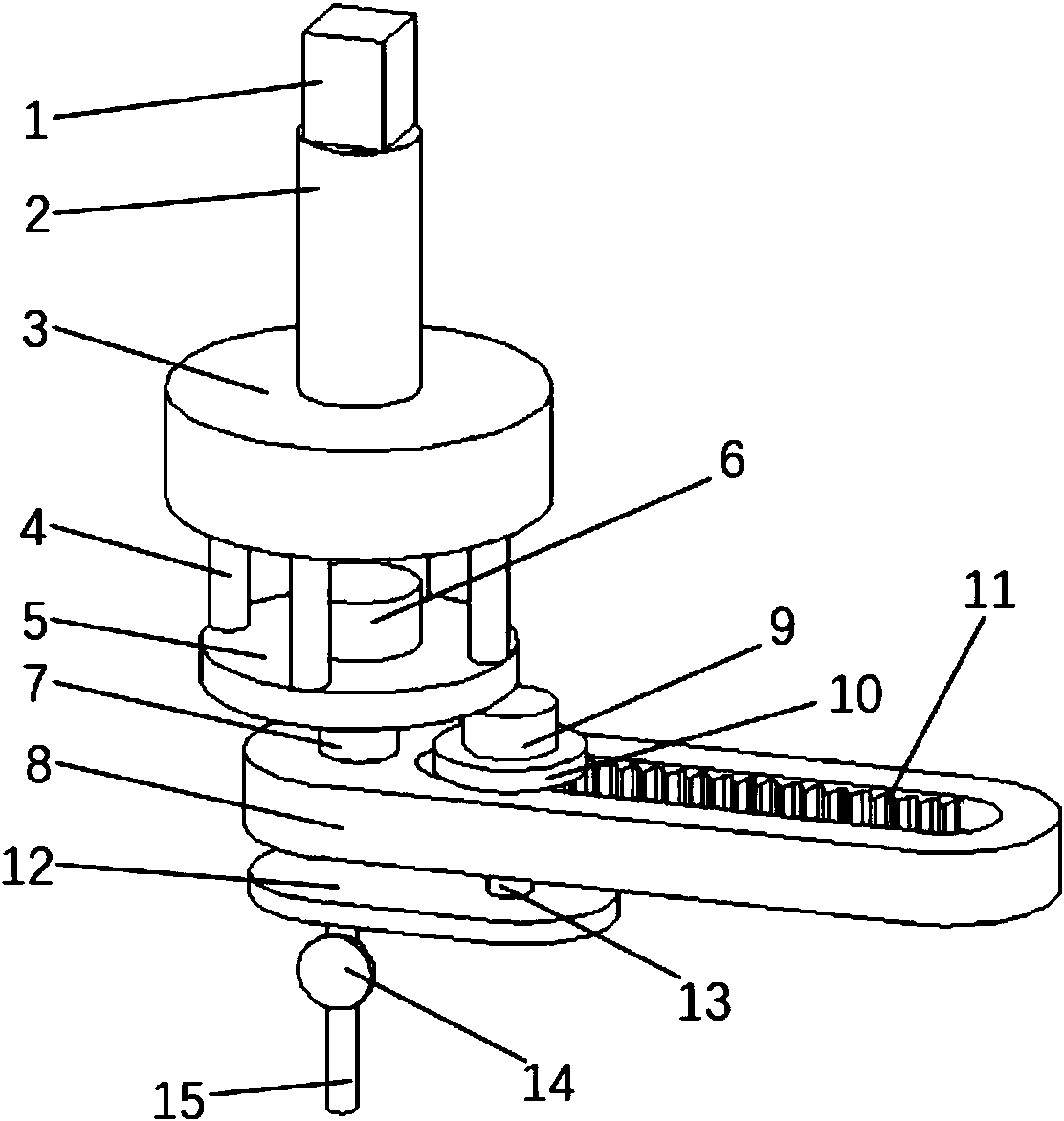

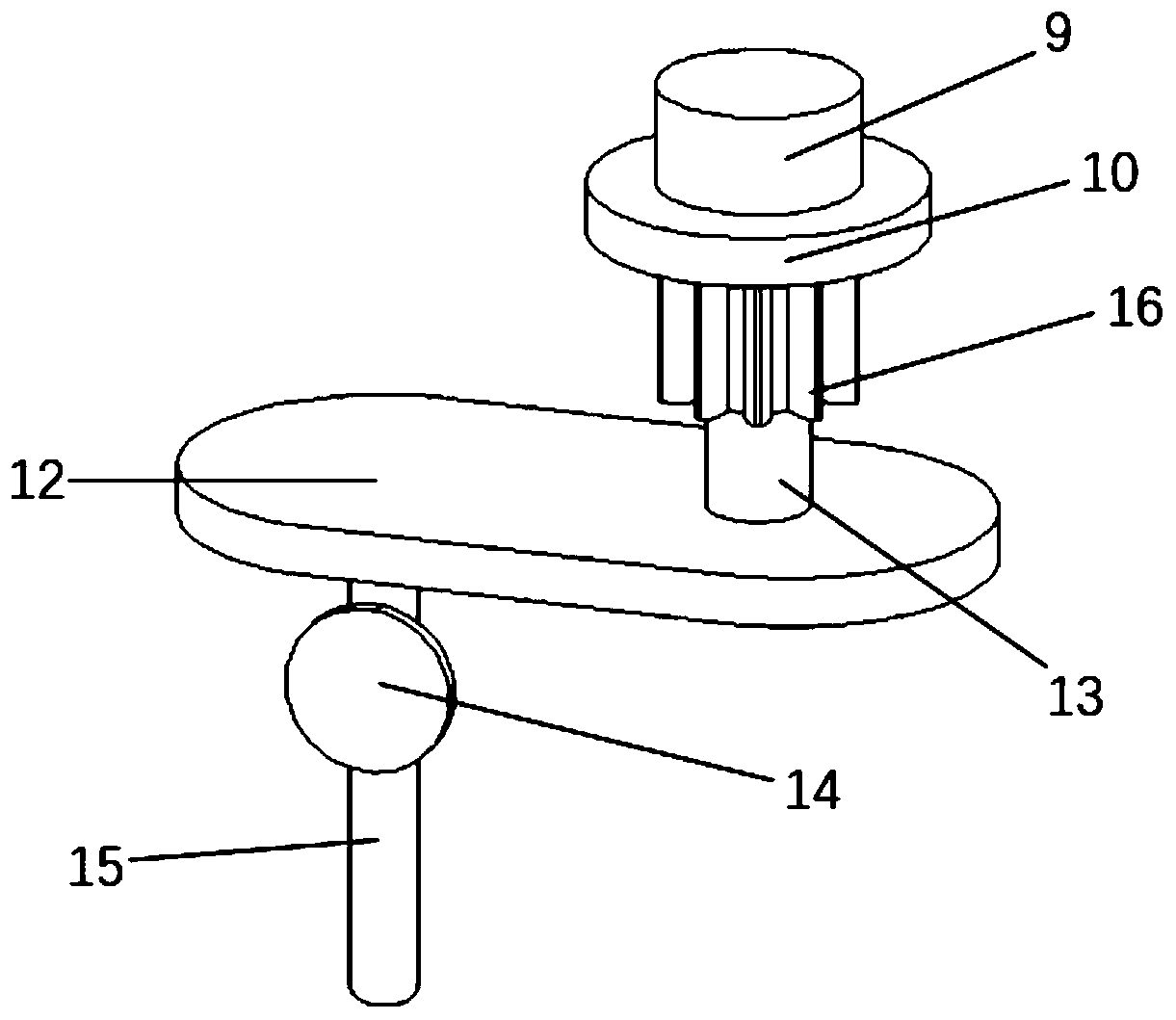

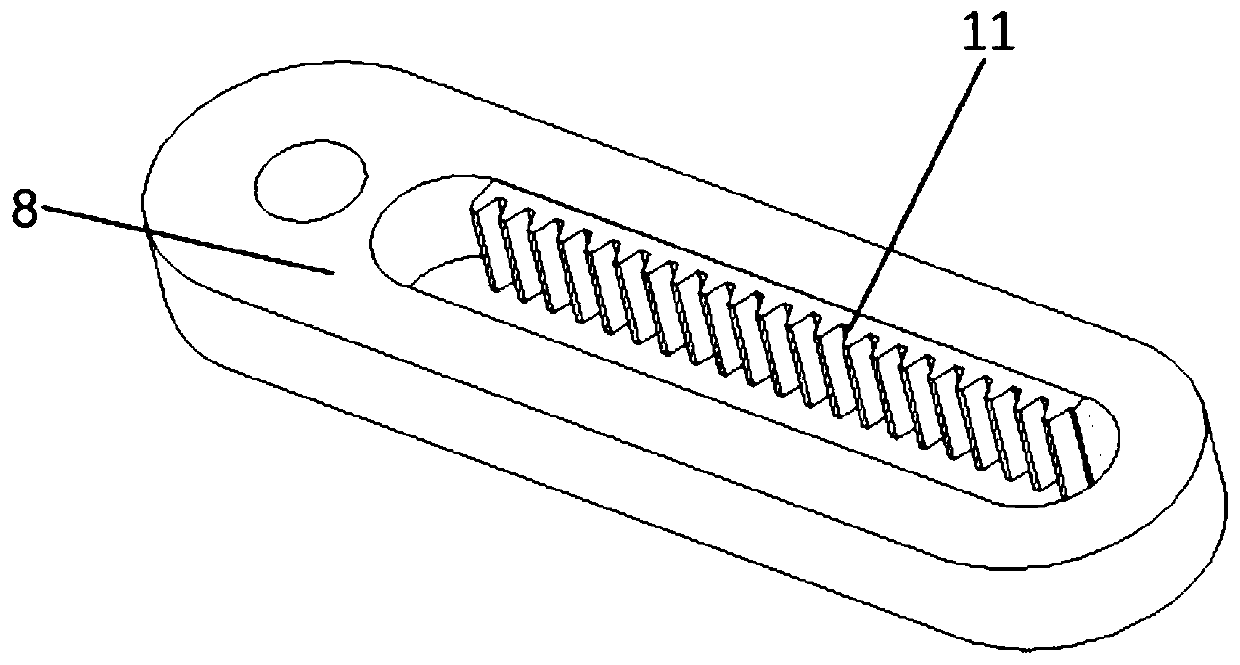

[0023] A hole system automatic alignment device for a CNC machining center, such as Figure 1-3 As shown, including the clamping and rotating device, the moving device and the controller;

[0024] The clamping and rotating device includes a first rotating shaft 7, a connecting rod 2, a mounting plate 5 and a support plate 3, such as figure 1 As shown; one end of the connecting rod 2 is fixedly provided with a clamp block 1, and the other end of the connecting rod 2 is fixedly connected with the top of the support plate 3, and the bottom of the support plate 3 is fixedly provided with several support columns 4 along the circumference, each support column The bottom end of 4 is fixedly connected with the top of the mounting plate 5, and the clamp block 1 or the connecting rod 2 is installed under the main shaft, so that the main shaft and the connecting rod 2 are in the same straight line during work; the top center of the mounting plate 5 is fixedly provided with a first Motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com