Printing plate with 3D effect and preparation method thereof

A 3D effect, plate technology, applied in the field of plate manufacturing, can solve the problems of long production cycle, large color film inventory, affecting production efficiency, etc., achieve good wear resistance and protection effect, solve poor printing effect, and improve operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

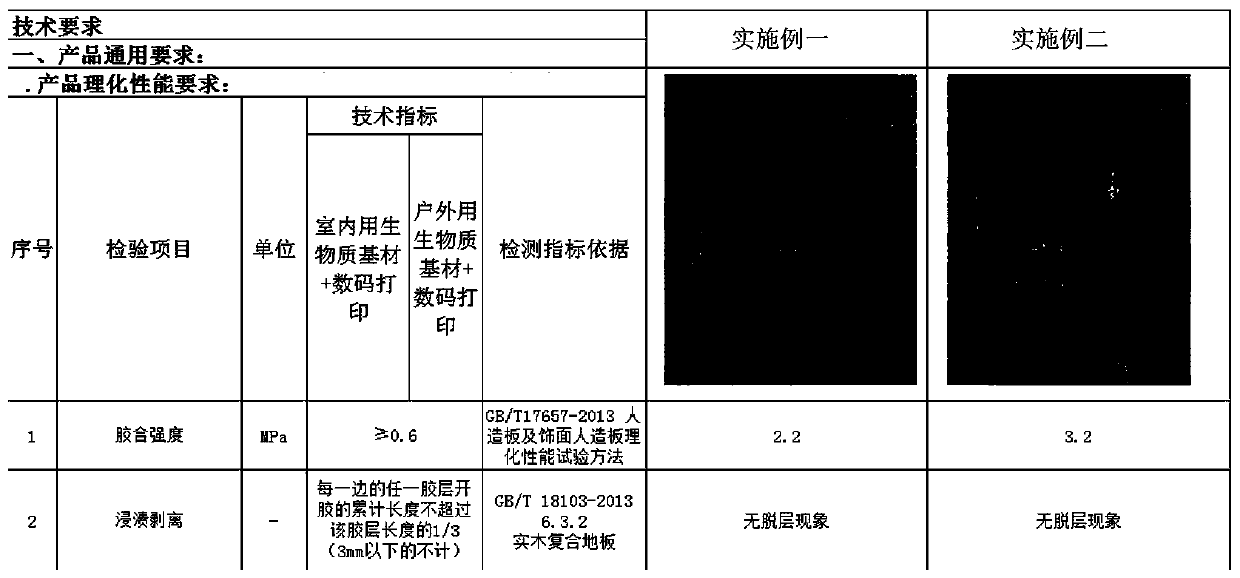

Examples

Embodiment 1

[0034] A printing plate with 3D effect, the plate comprises a base material layer, a color layer deposited on the base material layer and a UV protection layer covered on the color layer; the base material layer comprises a core layer and The background film layer combined with the core layer; the material of the core layer is PE-based wood plastic; the material of the background film layer is PVC; the texture of wood grain is also embossed on the background film layer. The color of the background film layer is covering white.

[0035] A method for preparing a printed board with 3D effects, comprising the following steps:

[0036] a. Add the raw materials constituting the core layer and their additives to the extruder, melt the raw materials constituting the core layer and their additives through the extruder, extrude them into the runner of the mold, and extrude from the die lip of the mould, Form the core material of PE-based wood-plastic material;

[0037] b. Grind the fr...

Embodiment 2

[0045] A printing plate with 3D effect, the plate comprises a base material layer, a color layer deposited on the base material layer and a UV protection layer covered on the color layer; the base material layer comprises a core layer and The background film layer combined with the core layer; the material of the core layer is PE plastic; the material of the background film layer is PE white film; the texture of wood grain is also embossed on the background film layer.

[0046] A method for preparing a printed board with 3D effects, comprising the following steps:

[0047] a. Add the raw materials constituting the core layer and their additives to the extruder, melt the raw materials constituting the core layer and their additives through the extruder, extrude them into the runner of the mold, and extrude from the die lip of the mould, Form the core material of PE-based wood-plastic material;

[0048] b. Grind the front and back sides of the core material, wear 0.5mm on each ...

Embodiment 3

[0056] A printing plate with 3D effect, the plate comprises a base material layer, a color layer deposited on the base material layer and a UV protection layer covered on the color layer; the base material layer comprises a core layer and The background film layer combined with the core layer; the material of the core layer is PE-based wood plastic; the material of the background film layer is PVC white film; the texture of wood grain is also embossed on the background film layer .

[0057] A method for preparing a printed board with 3D effects, comprising the following steps:

[0058] a. Add the raw materials constituting the core layer and their additives to the extruder, melt the raw materials constituting the core layer and their additives through the extruder, extrude them into the runner of the mold, and extrude from the die lip of the mould, Form the core material of PE-based wood-plastic material;

[0059] b. Grind the front and back sides of the core material, wear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com