Automatic climbing device for gate steel wire rope

An automatic climbing and steel wire rope technology, which is applied in the field of gate steel wire rope automatic climbing devices and gate maintenance devices, can solve problems such as high labor intensity, hidden safety hazards, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

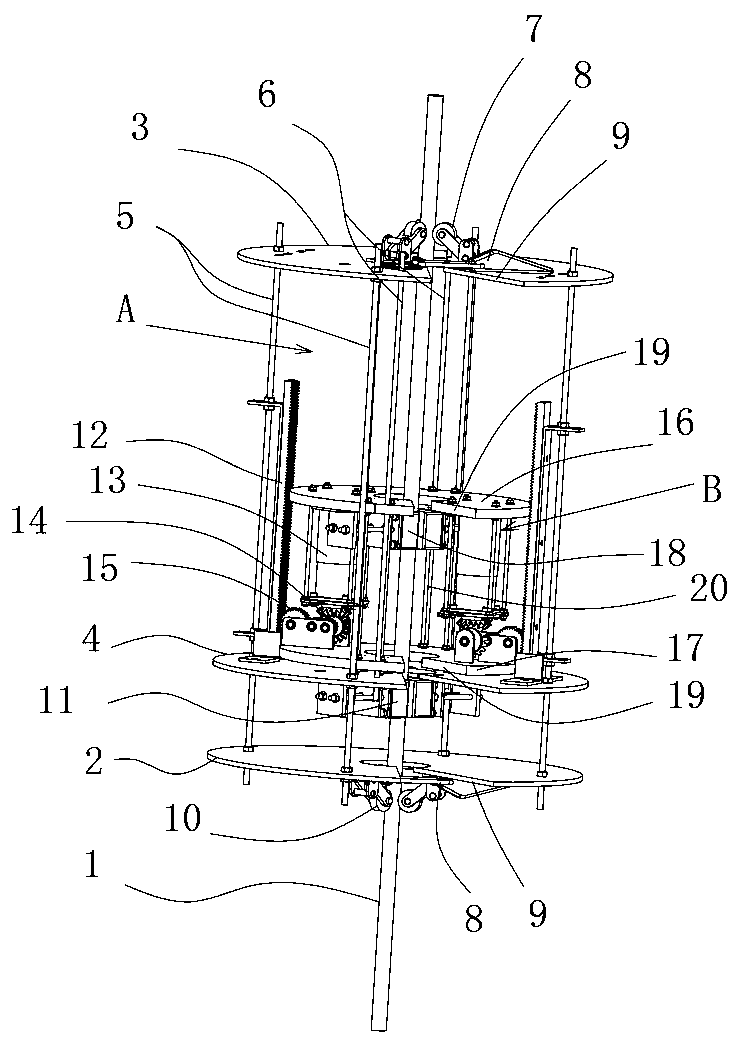

[0021] Embodiment 1: a kind of gate wire rope automatic climbing device, such as figure 1 shown. The device includes an outer frame A and an inner frame B slidably sleeved on the steel wire rope 1 of the gate. The outer frame A and the inner frame B are respectively provided with middle holes for the steel wire rope of the gate to pass through. A rack 12 is arranged on the outer frame, and a gear 15 engaged with the rack is arranged on the inner frame. Two sets of racks 12 and gears 15 are arranged symmetrically on both sides of the outer frame A and the inner frame B. The rack 12 extends along the axial direction of the gate wire rope 1, the gear is driven by a forward and reverse motor 13, and the outer frame A is provided with an outer clamping device 11 that can loosen / hold the gate wire rope. The inner frame B is provided with an inner clamping device 18 which can loosen / tighten the steel wire rope of the gate.

[0022] Outer frame A structure such as figure 1 As sho...

Embodiment 2

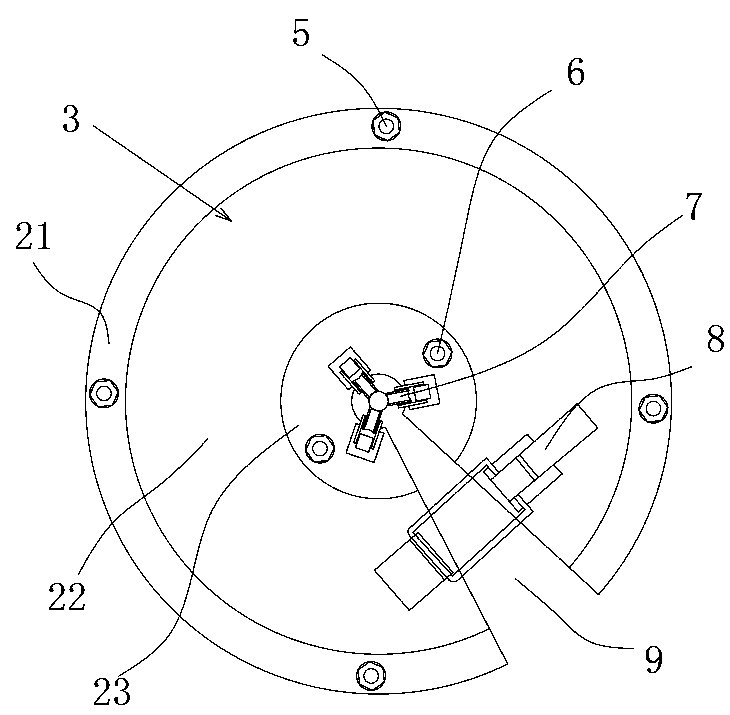

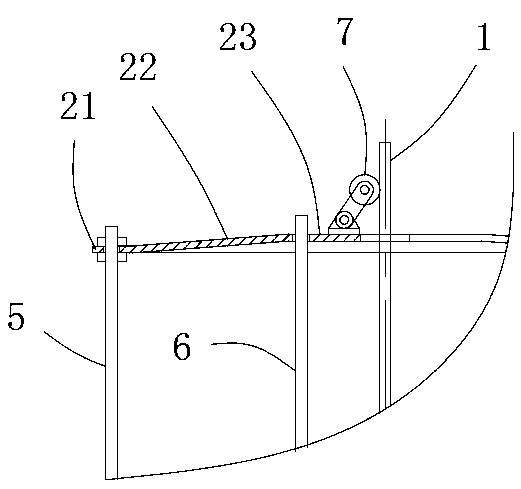

[0029] Embodiment 2, a kind of gate wire rope automatic climbing device with deformation guide, such as figure 2 , 3 shown. In this embodiment, the upper mounting plate 3 , the middle mounting plate 4 and the lower mounting plate 2 of the outer frame are non-flat plate structures. Such as figure 2 , 3 As shown, the above mounting plate 3 is taken as an example. The outer circumference 21 of the upper mounting plate is a plane, and the inner circumference 23 is a plane. The cam lock 8 is arranged on the tapered surface of the fan-shaped slot 9 . The inclination angle of the conical surface is 5 degrees, and the conical surface of the upper mounting plate can also be inclined downward. The board surface structure of the lower mounting plate 2 and the middle mounting plate 4 is identical with the upper mounting plate, and the direction of the lower mounting plate 2 and the middle mounting plate 4 taper surfaces can be the same as or opposite to the upper mounting plate.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com