Filling method of soft bag transfusion products

A soft bag infusion and product technology, which is applied in the field of medical product production, can solve the problems of inability to effectively discharge the gas in the infusion bag, no gas guide mechanism, overflow of the liquid storage space, etc., to reduce the unqualified problems of filling overflow, Improve the time cycle and reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

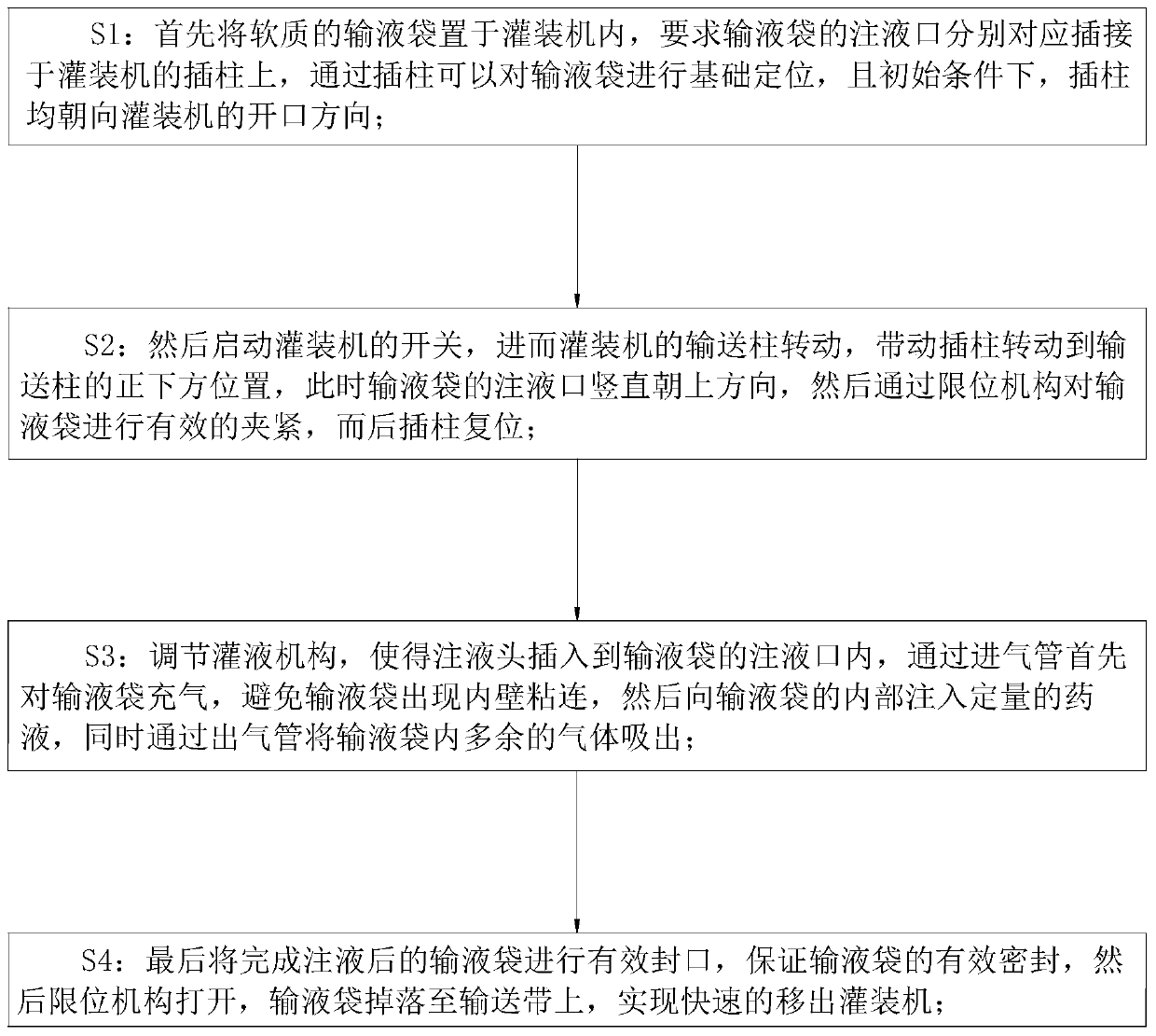

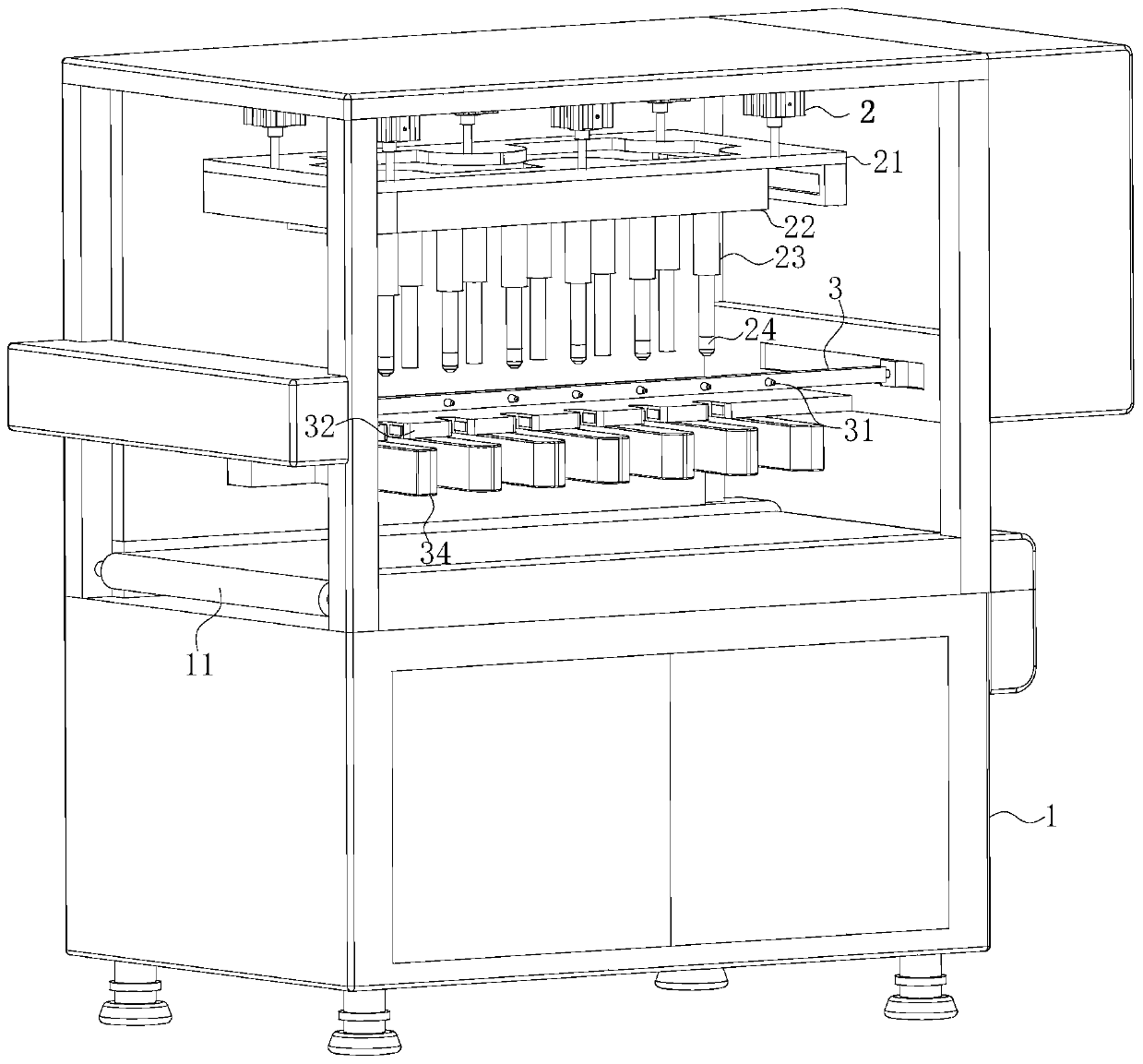

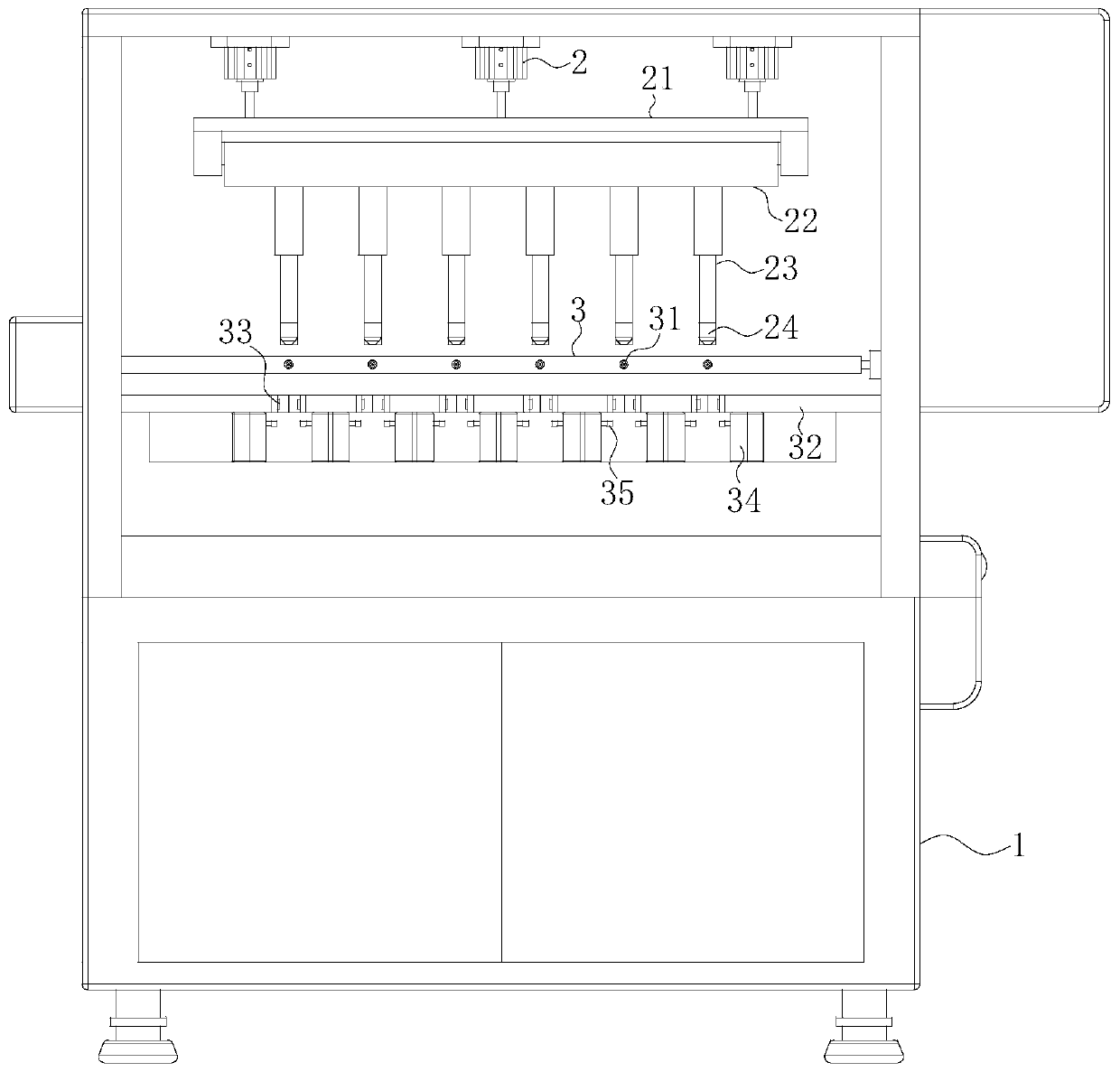

[0028] Such as Figure 1 to Figure 5 Shown, the filling method of a kind of soft bag transfusion product of the present invention, this filling method comprises the following steps:

[0029] S1: First place the soft infusion bag in the filling machine, and the injection ports of the infusion bag are required to be plugged into the inserting posts 31 of the filling machine respectively, and the infusion bag can be basically positioned through the inserting posts 31, and Under the initial conditions, the inserts 31 are all facing the opening direction of the filling machine; by setting the inserts 31, the infusion bag can be quickly and initially fixed and positioned, avoiding the difficulty of direct precise positioning, and playing the role of tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com