A kind of polyurethane corner glue with high bonding strength and preparation method thereof

A technology of polyurethane and corner glue, used in polyurea/polyurethane adhesives, non-polymer adhesive additives, adhesives, etc., can solve the problems of instability and high viscosity of polyurethane adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

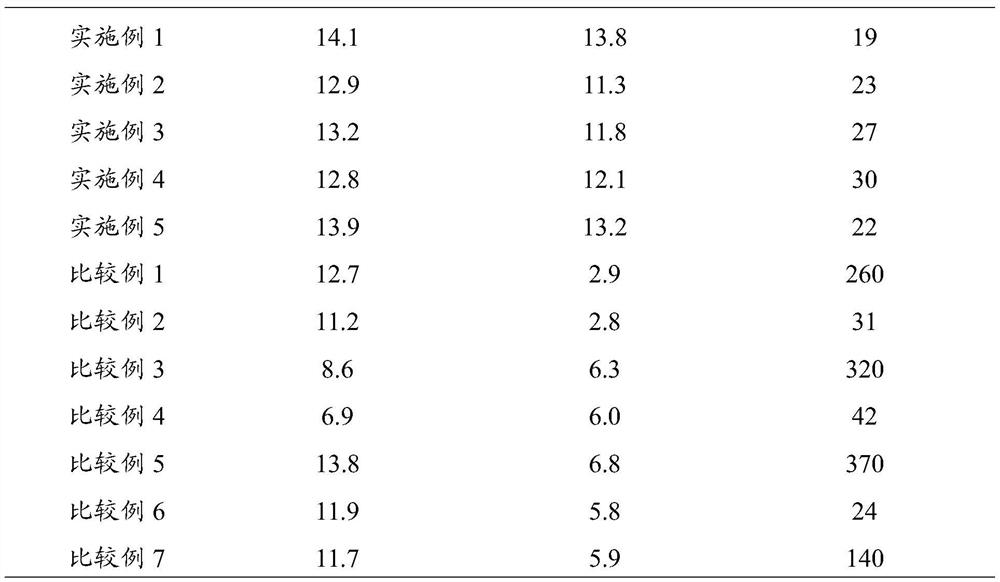

Examples

preparation example Construction

[0049] The present invention provides a kind of preparation method of the polyurethane group corner glue of high bonding strength described in above-mentioned technical scheme, comprises the following steps:

[0050] Mix the polyurethane prepolymer, plasticizer, filler, catalyst, defoamer and modified hydrophilic silica at 20-70°C, and stir for 2-5 hours to obtain high-adhesive-strength polyurethane corner glue;

[0051] The polyurethane prepolymer is composed of isocyanate, difunctional polyether polyol, tetrafunctional polyether polyol and trifunctional polyether polyol with a mass ratio of 30-50:3-10:3-10:30-60 made by reaction;

[0052] The modified hydrophilic white carbon black is prepared by reacting epoxy silane with a mass ratio of 1-10:100 and hydrophilic white carbon black.

[0053] In the present invention, the types and amounts of the polyurethane prepolymer, plasticizer, filler, catalyst, defoamer and modified hydrophilic silica are consistent with those describ...

Embodiment 1

[0060] Preparation of isocyanate-terminated polymers:

[0061] Add 200g trifunctional polyether polyol (average molecular weight 5000g / mol), 20g difunctional polyether polyol (average molecular weight 400g / mol), 20g tetrafunctional polyether polyol (average molecular weight 400g / mol) to In a reactor equipped with mechanical stirring, vacuum, nitrogen protection and heating device, stir at 90°C and dry in vacuum for 3h; then cool down to 30°C, add 180g of diphenylmethane diisocyanate, react at 70°C for 2h under vacuum, then The temperature is lowered to <40°C, and the isocyanate-terminated polymer is obtained after discharging. The R value of the isocyanate-terminated polymer is 3.42;

[0062] Preparation of modified hydrophilic silica:

[0063] Disperse 20g of hydrophilic silica A380 in 100g of toluene solution, stir and disperse at 110°C for 30min; then add 2g of γ-glycidyl etheroxypropyl trimethoxysilane, continue to stir and disperse at 110°C for 120min, cool, filter, and ...

Embodiment 2

[0071] Preparation of isocyanate-terminated polymers:

[0072] Add 200g trifunctional polyether polyol (average molecular weight 5000g / mol), 20g difunctional polyether polyol (average molecular weight 400g / mol), 20g tetrafunctional polyether polyol (average molecular weight 400g / mol) to In a reactor equipped with mechanical stirring, vacuum, nitrogen protection and heating device, stir at 90°C and dry in vacuum for 3h; then cool down to 30°C, add 180g of diphenylmethane diisocyanate, react at 70°C for 2h under vacuum, then The temperature was lowered to <40°C, and the material was discharged to obtain an isocyanate-terminated polymer. The R value of the isocyanate-terminated polymer was 3.42;

[0073] Preparation of modified hydrophilic silica:

[0074] Disperse 20g of hydrophilic silica A380 in 100g of toluene solution, stir and disperse at 110°C for 30min; then add 1g of γ-glycidyl etheroxypropyl trimethoxysilane, continue to stir and disperse at 120°C for 100min, cool, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com