Floorslab thickness control tool

A technology of thickness control and tools, which is applied in the direction of construction, building structure, and building material processing, and can solve the problems of concrete being difficult to vibrate and compact, displacement, and floor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

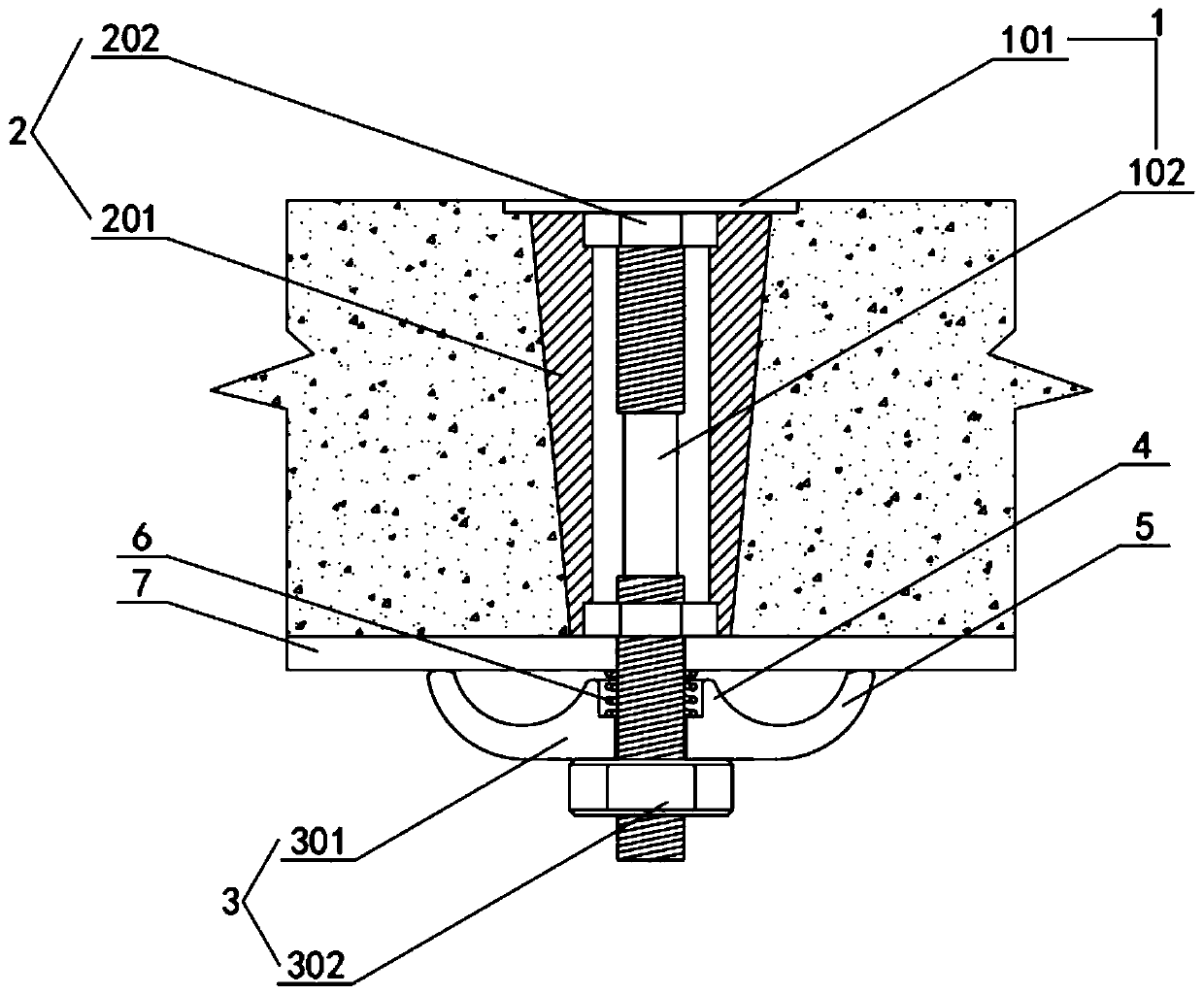

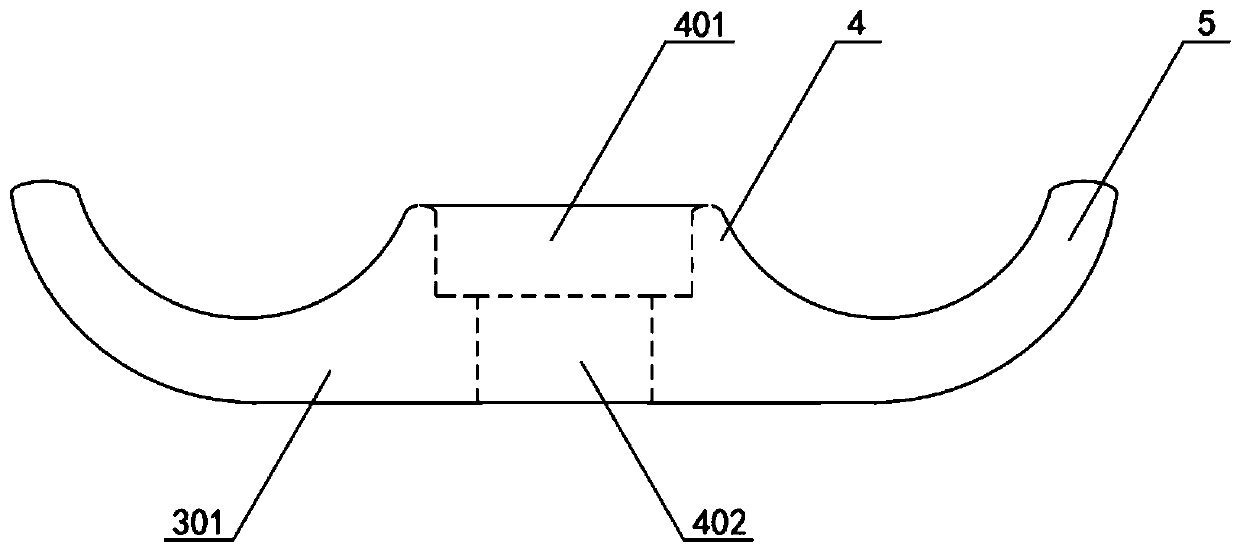

[0021] refer to Figure 1-2 , a floor thickness control tool, including a pre-embedded mechanism 1, a multifunctional casing mechanism 2 and a locking mechanism 3, the pre-embedded mechanism 1 includes a fixed steel plate 101 and a fixed screw 102 fixed to the bottom of the fixed steel plate 101 , the upper and lower ends of the fixed screw 102 are respectively provided with corresponding locking external threads, and the diameter of the middle part of the fixed screw 102 is smaller than the minor diameter of the locking external threads; Fixing piece 201, the center of the rounded table-shaped fixing piece 201 is vertically provided with a corresponding communication hole, and the upper and lower ends of the communication hole are respectively inlaid with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com