Concrete connected silo reinforcing structure and method

A technology for strengthening structures and concrete, which is applied in the direction of building construction, building maintenance, building types, etc., can solve the problems of multiple steel strand materials, improve bearing capacity and crack resistance, ensure structural durability, and have good reinforcement effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

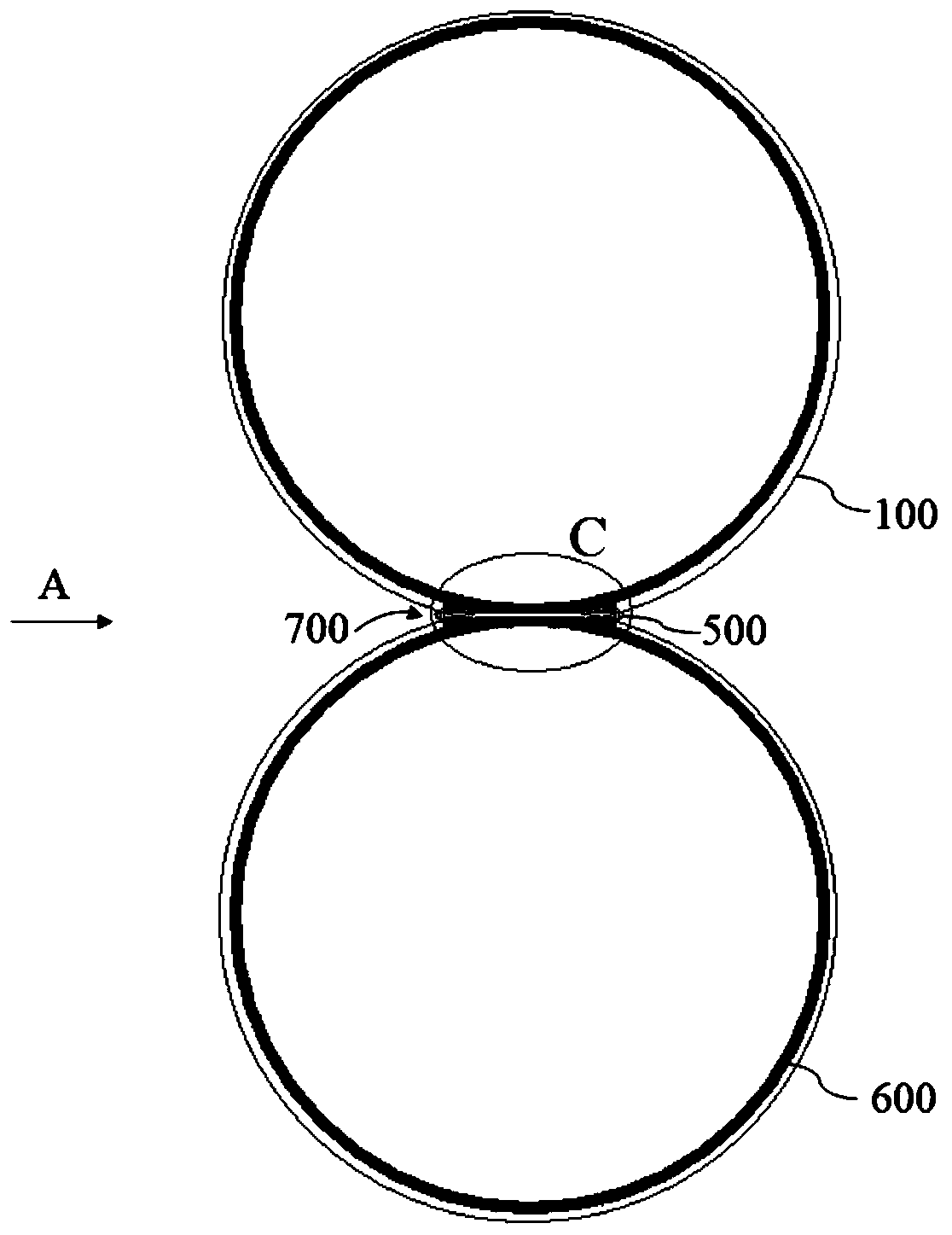

[0045] figure 1 The case of two silos conjoined is shown, with only one contact. A reinforced concrete silo structure in this embodiment includes prestressed tendons 100 and anchors 500 .

[0046] combine Figure 6 , 7 , 8, the contact portion 700 of the silo wall 600 of two adjacent silos is provided with a main hole 300 and a secondary hole 400, the main hole 300 is a through hole penetrating the contact portion from the tangential direction of the silo wall, and the secondary holes 400 are two groups , are arranged on both sides of the main hole 300, and in each group, there are two secondary holes 400 which are respectively arranged at both ends of the main hole 300, and the secondary holes communicate with the main hole.

[0047] combine figure 1 , taking the upper silo as an example, the prestressed tendon 100 surrounds the silo wall of one of the silos, the left end of the prestressed tendon passes through the secondary hole, the main hole, and the secondary hole fr...

Embodiment 2

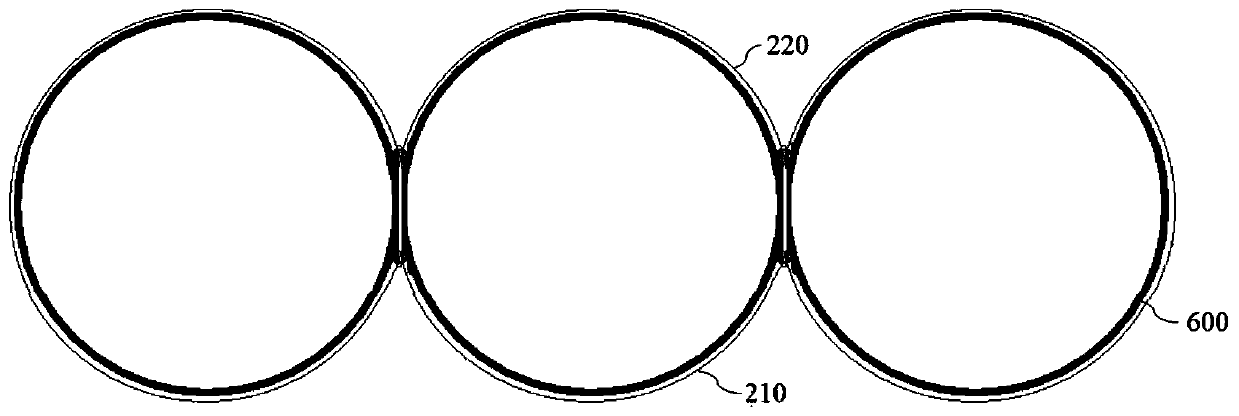

[0052] figure 2 Shown is the case of three silos connected side by side, the silo in the middle forming two contacts with the adjacent silos.

[0053] The arrangement of the prestressed tendons of this embodiment can be the same as that of Embodiment 1, and a prestressed tendon 100 is passed through the secondary hole and the main hole of the two contact parts 700, and finally the end of the prestressed tendon is contacted. For example, the prestressed tendon directly passes through the hole of one of the contact parts, and the two ends are tensioned and anchored by the anchor in the main hole of the other contact part.

[0054] Since there are two contact parts, it is not convenient to use a prestressed tendon to penetrate the holes of the two contact parts. This embodiment can also use figure 2 The way shown in , that is, the prestressed tendons are divided into two sections, namely the first prestressed tendons 210 and the second prestressed tendons 220, and the two cont...

Embodiment 3

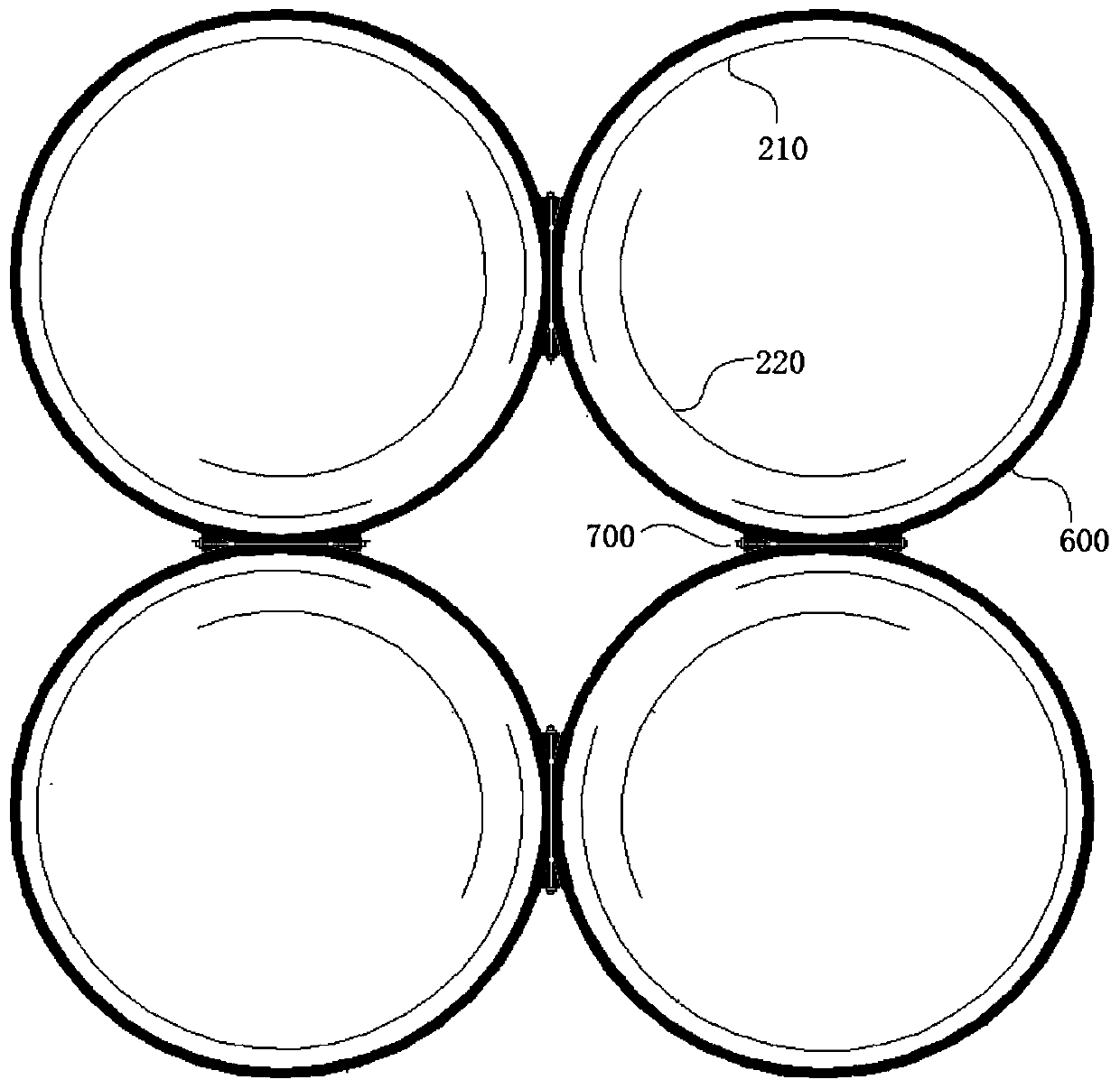

[0057] Figure 4 A situation in which 6 silos are connected is shown, wherein the two silos in the middle form 3 contact portions with the surrounding silos respectively.

[0058] For a silo with three contacts, three types of anchoring are possible. (1) Adopt the anchoring form of Embodiment 1, that is, use a prestressed tendon to surround the warehouse wall and be tensioned and anchored by the anchor. (2) adopt Figure 4 In the anchoring form shown, the three contact parts (401, 402, 403) divide the warehouse wall into three sections, including two 1 / 4 arcs and one 1 / 2 arc, using three sections of prestressed tendons, respectively Two fourth prestressed tendons 240 and one third prestressed tendon 230, the length of the fourth prestressed tendon 240 is greater than 1 / 4 of the outer perimeter of the warehouse wall, and the length of the third prestressed tendon 230 is greater than 1 / 4 of the outer perimeter of the warehouse wall 1 / 2, the three sections of prestressed tendo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com