Structure for prefabricating bridge deck slab and reducing cracks in severe area and construction method thereof

A bridge deck and regional technology, which is applied to bridge deck prefabrication and crack reduction structures and construction fields in harsh areas, can solve the problem that the construction effect cannot meet the design and specification requirements, the bottom surface of the prefabricated parts is difficult to be flat and hard, and the storage and maintenance cycle long and other problems, to achieve good economic and social benefits, simple and convenient shape change, and high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments, but the following embodiments are only preferred embodiments of the present invention, not all. Based on the examples in the implementation manners, other examples obtained by those skilled in the art without making creative efforts all belong to the protection scope of the present invention. The experimental methods in the following examples, the materials, reagents, control system and related components controlled by it, and sensing technology, etc., are all conventional techniques and methods, and can be obtained from commercial sources, unless otherwise specified.

[0041] Example:

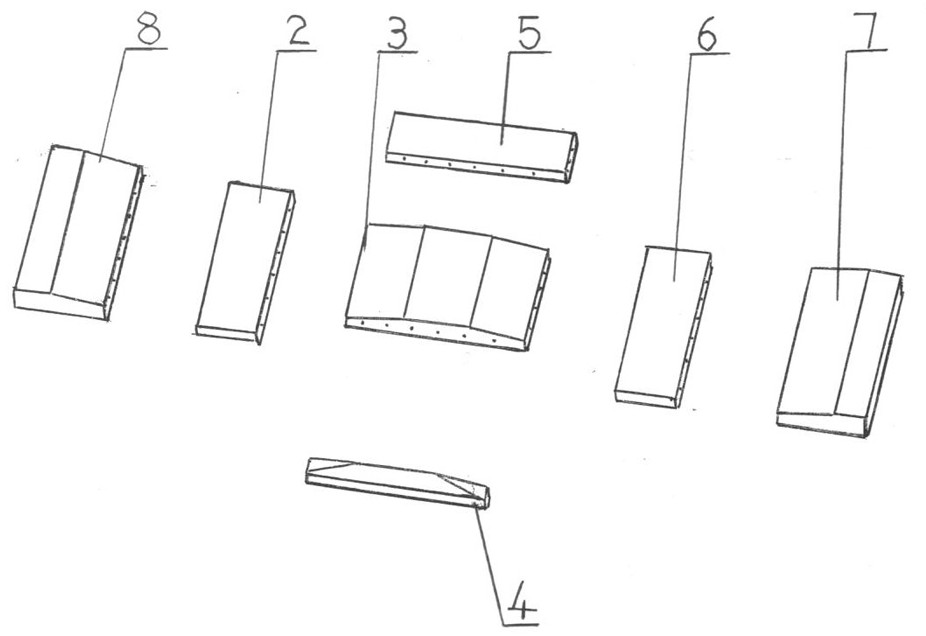

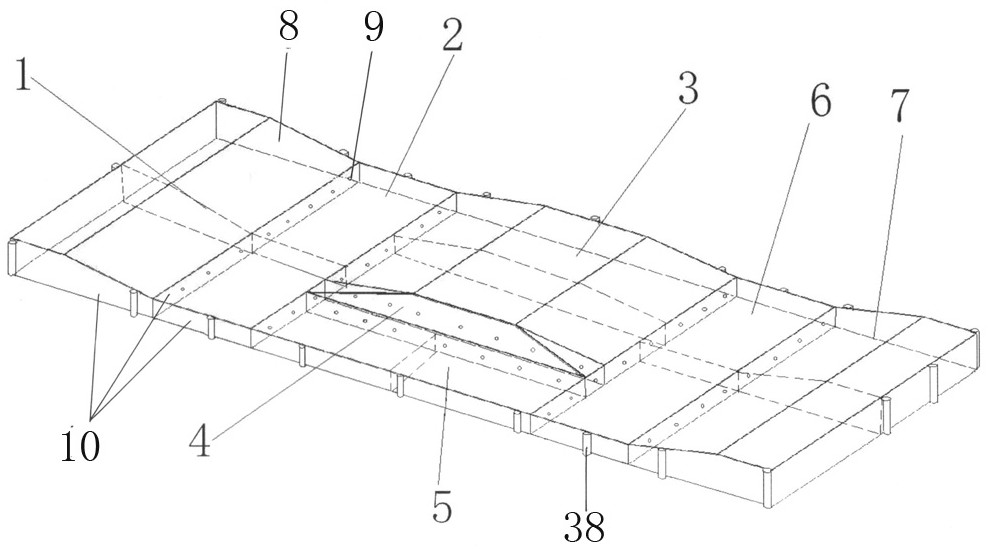

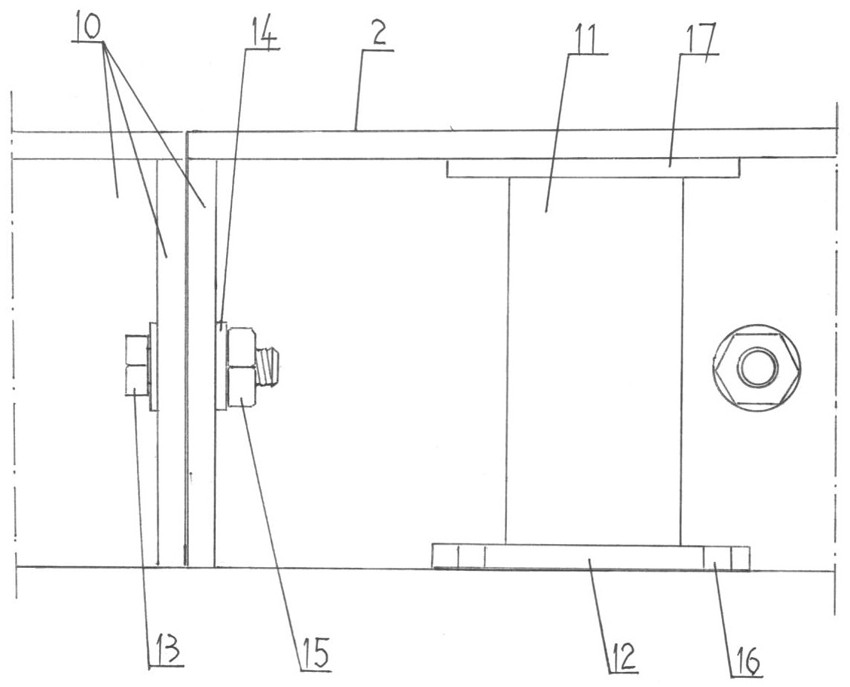

[0042] Such as Figure 1 to Figure 7 As shown, a bridge deck prefabrication and crack reduction structure and its construction method in harsh areas, the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com