Second-liner branch warehouse pouring construction equipment for large-section tunnel and construction method

A technology of construction equipment and large cross-section, applied in the direction of tunnel lining, tunnel, mining equipment, etc., can solve the problem of difficult to guarantee the quality of concrete construction, and achieve the effect of sufficient working space for personnel, guaranteeing construction safety, and guaranteeing construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

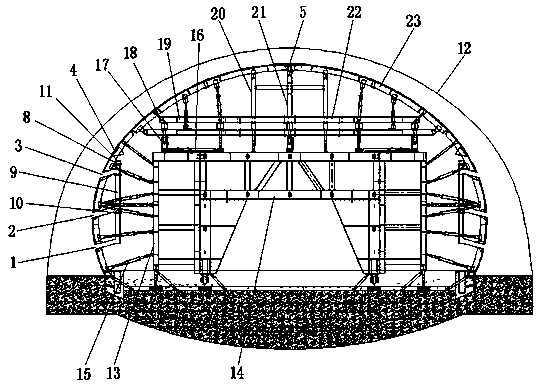

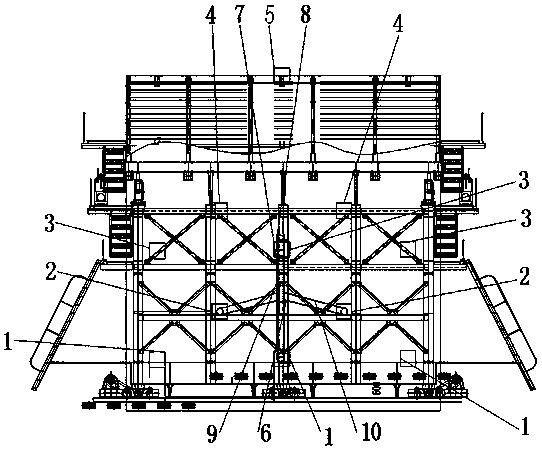

[0037] figure 1 The front view of the construction equipment for pouring the second lining in separate bins provided by this embodiment; image 3 for figure 1 side view.

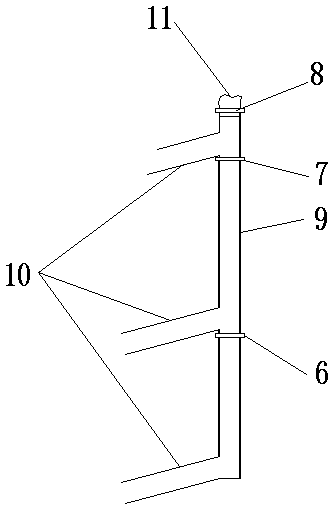

[0038] Such as Figure 1-3 As shown, this embodiment provides a large-section tunnel two-lining sub-bin pouring construction equipment, including a formwork unit 12, an adjustment support unit and a portal unit, and the adjustment support unit is arranged between the formwork unit 12 and the portal unit. The unit 12 is provided with a reinforced back rib 23, one end of the adjustable support unit is connected to the reinforced back rib 23, and the other end of the adjusted support unit is connected to the door frame unit; the formwork unit 12 is provided with a first-level window 1, a second-level window 2, The third-level window 3 and the fourth-level window 4, the top of the formwork unit 12 is provided with a dome window 5; it also includes an interconnected ground pump and a concrete distribution unit...

Embodiment 2

[0045] Figure 4 Schematic diagram of different pouring areas for the second lining provided in this embodiment; Figure 5 Schematic diagram of pouring for first-level window 1; Figure 6 Schematic diagram of pouring for secondary window 2; Figure 7 Schematic diagram of pouring for the third-level window 3; Figure 8 Schematic diagram of pouring for the dome window 5.

[0046] This embodiment utilizes the construction equipment for pouring the second lining of the large-section tunnel in the embodiment 1 to carry out construction. The method includes the following steps:

[0047] Step 1: Open the first-level window 1, the operator is in place, and install the concrete distribution units on both sides;

[0048] Step 2: pumping concrete through the first-level window 1, so that the concrete pouring plane in the formwork unit 12 is flush with the first-level window 1;

[0049] Step 3: Open the secondary window 2, and pump concrete through the secondary window 2, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com