Pipe fixing device

A technology for fixing devices and pipes, which is applied in the direction of pipe components, pipe supports, pipes/pipe joints/pipe fittings, etc., which can solve the problems of difficult to fully match the diameter of steel pipes and low versatility, so as to improve the flexibility and versatility of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

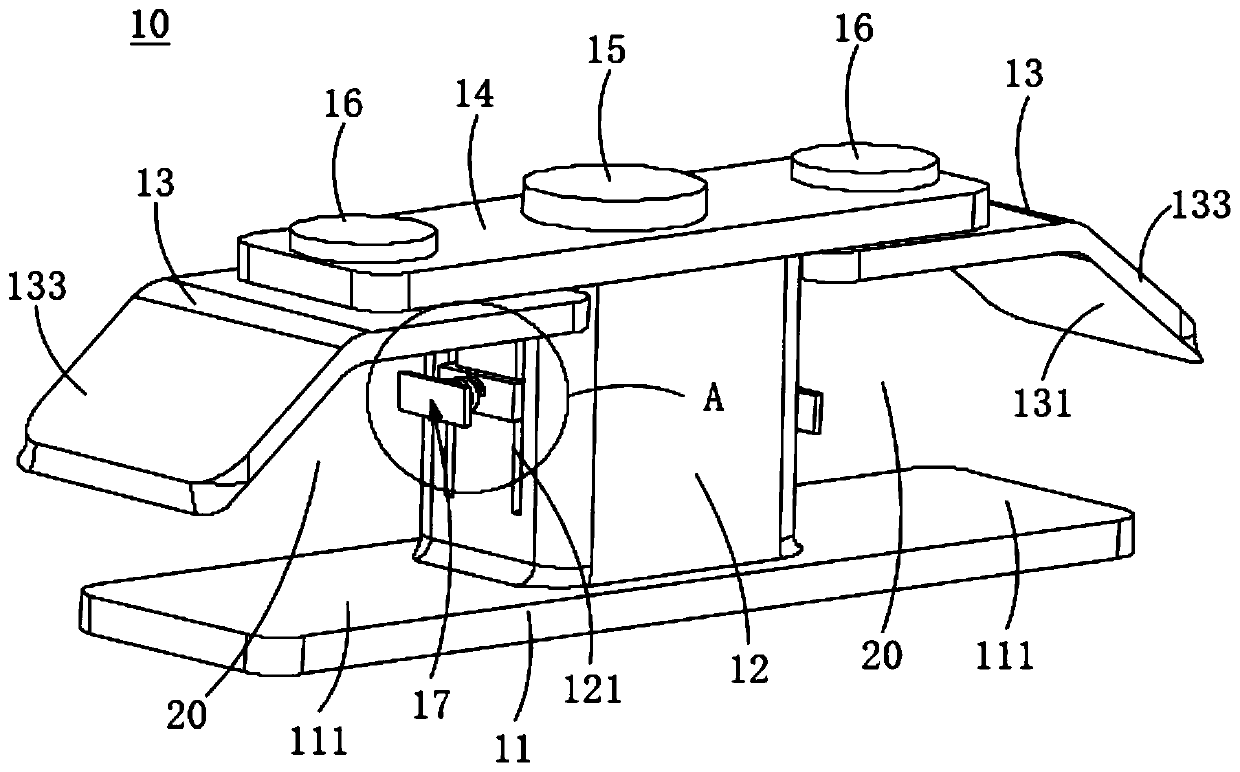

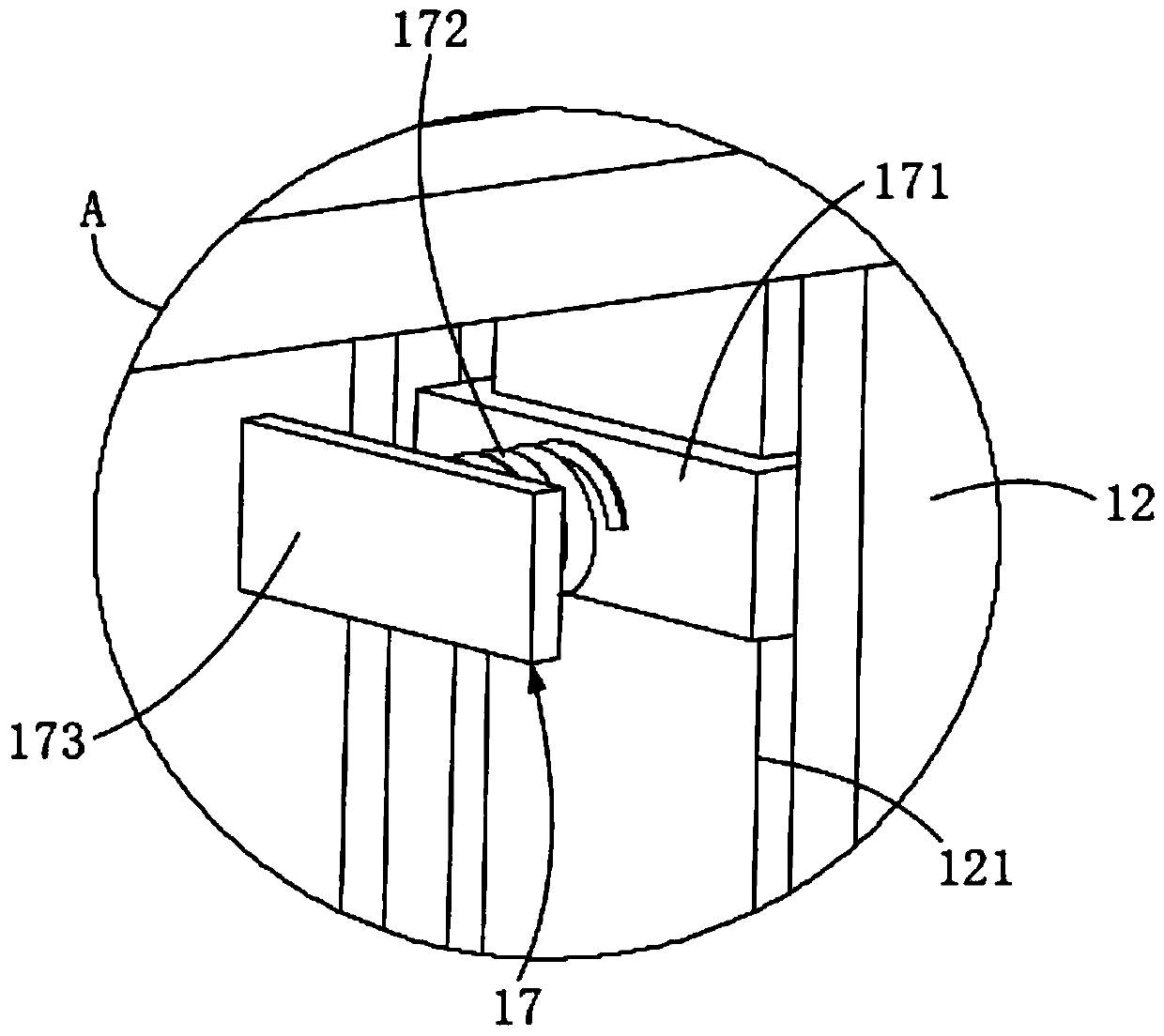

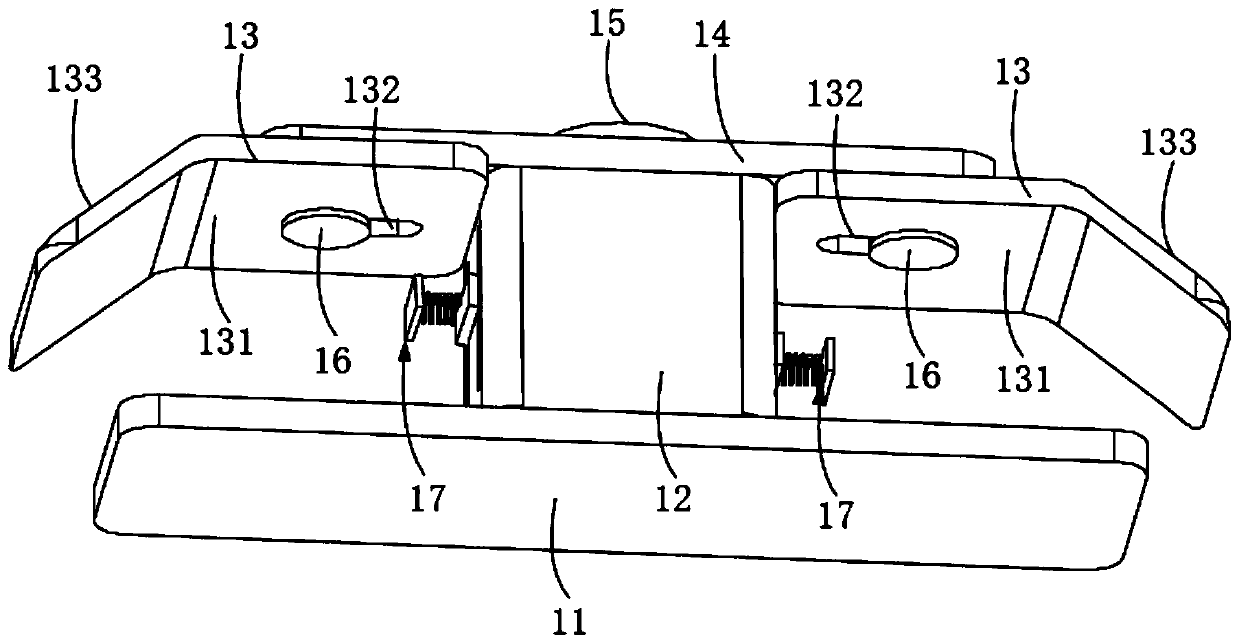

[0036] Such as figure 1 , image 3 and Figure 4 As shown, the pipe fixing device provided by this embodiment includes a pipe clamp 10 with a clamping groove; the clamping groove 20 has a first pressing surface 131 and a second pressing surface 111, and the first pressing surface 131 and the second pressing surface The pressing surfaces 111 are opposite and arranged at intervals, and the first pressing surface 131 can move closer and away from the second pressing surface 111 along the first direction and the second direction, so that the locking groove 20 is locked or released at the position Clamp the pipe body in the groove 20; the first direction is the vertical direction, and the second direction is perpendicular to the first direction.

[0037] Among them, with Figure 4 Take the placement position in , as an example, the first direction is the up-down direction, and the second direction is the left-right direction.

[0038] In this embodiment, the pipe body is the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com