Cleaning type belt powder conveying system and conveying method thereof

A powder conveying and belt technology, applied in the clean belt powder conveying system and its conveying field, can solve the problems of dirty surface, reduced production efficiency, waste of production time, etc., to increase flexibility and versatility, improve Safety and convenience, increasing convenience and variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

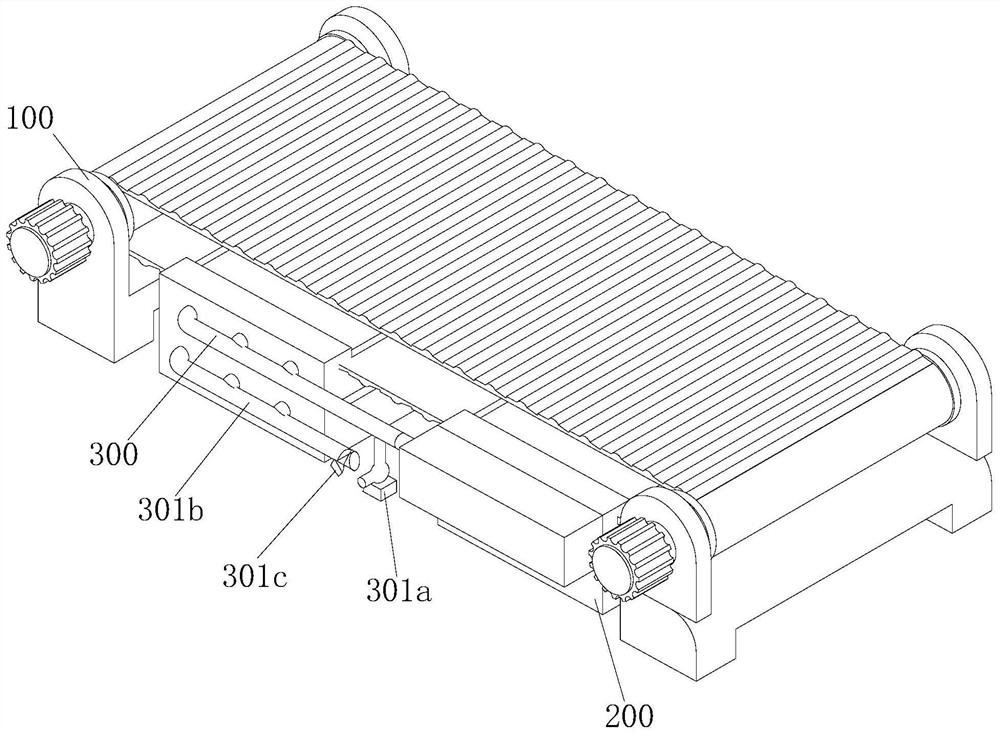

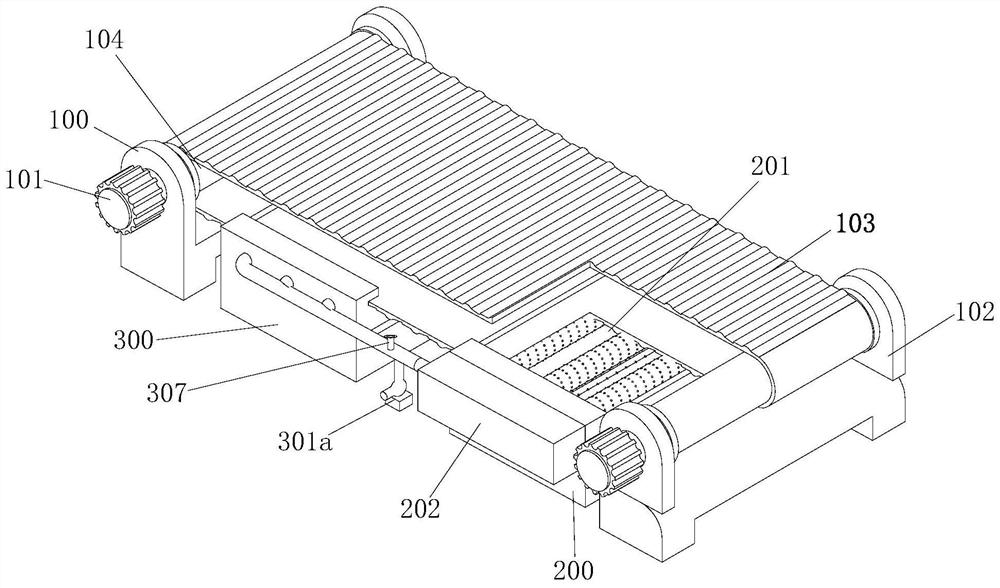

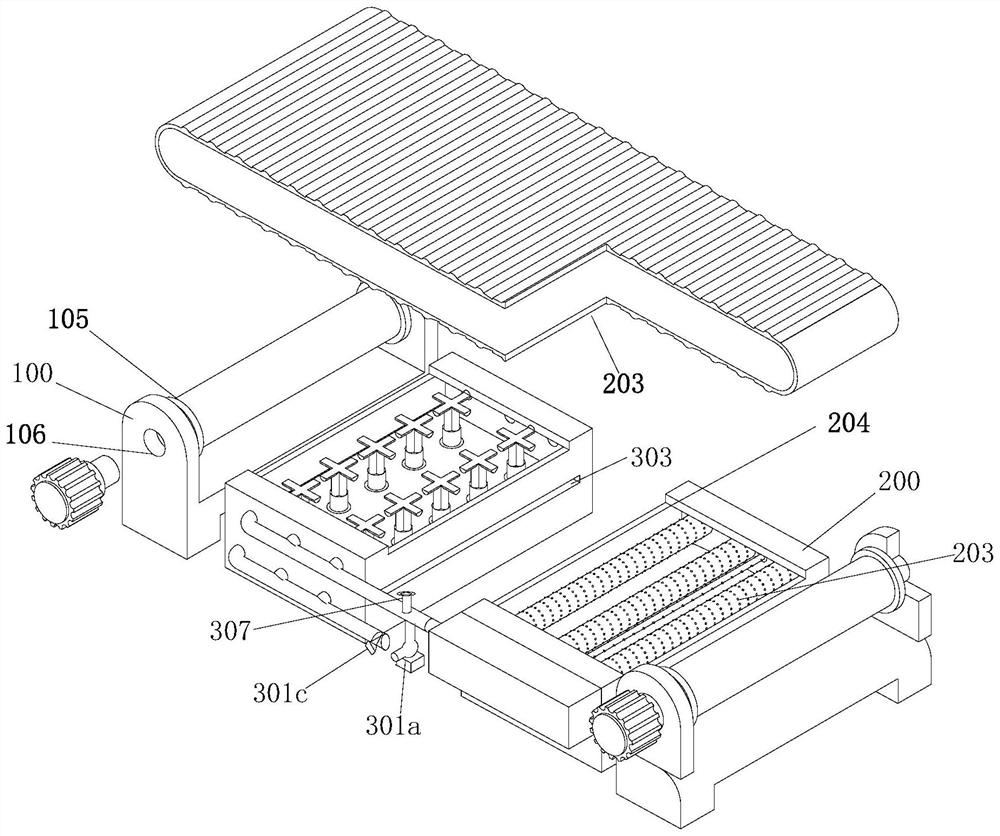

[0031] like Figure 1-Figure 5 As shown, according to an aspect of the present invention, the present invention provides a cleaning belt powder conveying system, comprising a first support block 100, a cleaning box 200 and a drying box 300, one side of the first support block 100 is provided with The second support block 102, the first support block 100 and the second support block 102 are movably connected with rollers 104, the outer sides of the pair of rollers 104 are movably connected with a conveyor belt 103, and below one end of the conveyor belt 103 is movably connected with a cleaning box 200 , a drying box 300 is movably connected to one side of the cleaning box 200 under the other end of the conveyor belt 103; the first support block 100 and the second support block 102 are placed on the ground, and then the first motor 101 is turned on to drive the roller 104 to rotate , a pair of rollers 104 drive the conveyor belt 103 to rotate, and then convey the materials on th...

Embodiment 2

[0037] Embodiment 2, in the present invention, as figure 1 and image 3 As shown, a temperature and humidity sensor 307 is provided on the first gas delivery pipe 301, the drying box 300 is also movably connected with a second gas delivery pipe 301b through the hole 302, and a second gas delivery pump 301c is connected to the second gas delivery pipe 301b. By the second air pump 301c, the external hot air is transported to the drying box along the second air pipe to directly dry the conveyor belt, and when the second motor in the drying box 300 is running at high speed, it will generate in the outer cover. A lot of heat, the hot air in the outer cover is quickly transported along the first air pipe to the drying box through the first conveying pump. Suspend the delivery of hot air into the drying box through the second air pipe. At this time, only the other generated when the second motor is running is transported to the drying box to dry the conveyor belt.

[0038] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com