Pipeline rotating joint

A technology of rotary joints and pipes, applied in the directions of pipes/pipe joints/pipe fittings, adjustable connections, passing elements, etc., can solve the problems of increasing the displacement space configuration requirement, improving the engineering difficulty factor, and the large amount of pipeline moving engineering, etc. Improve the stability of the structure configuration, the guarantee of structural strength, and the lightness of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

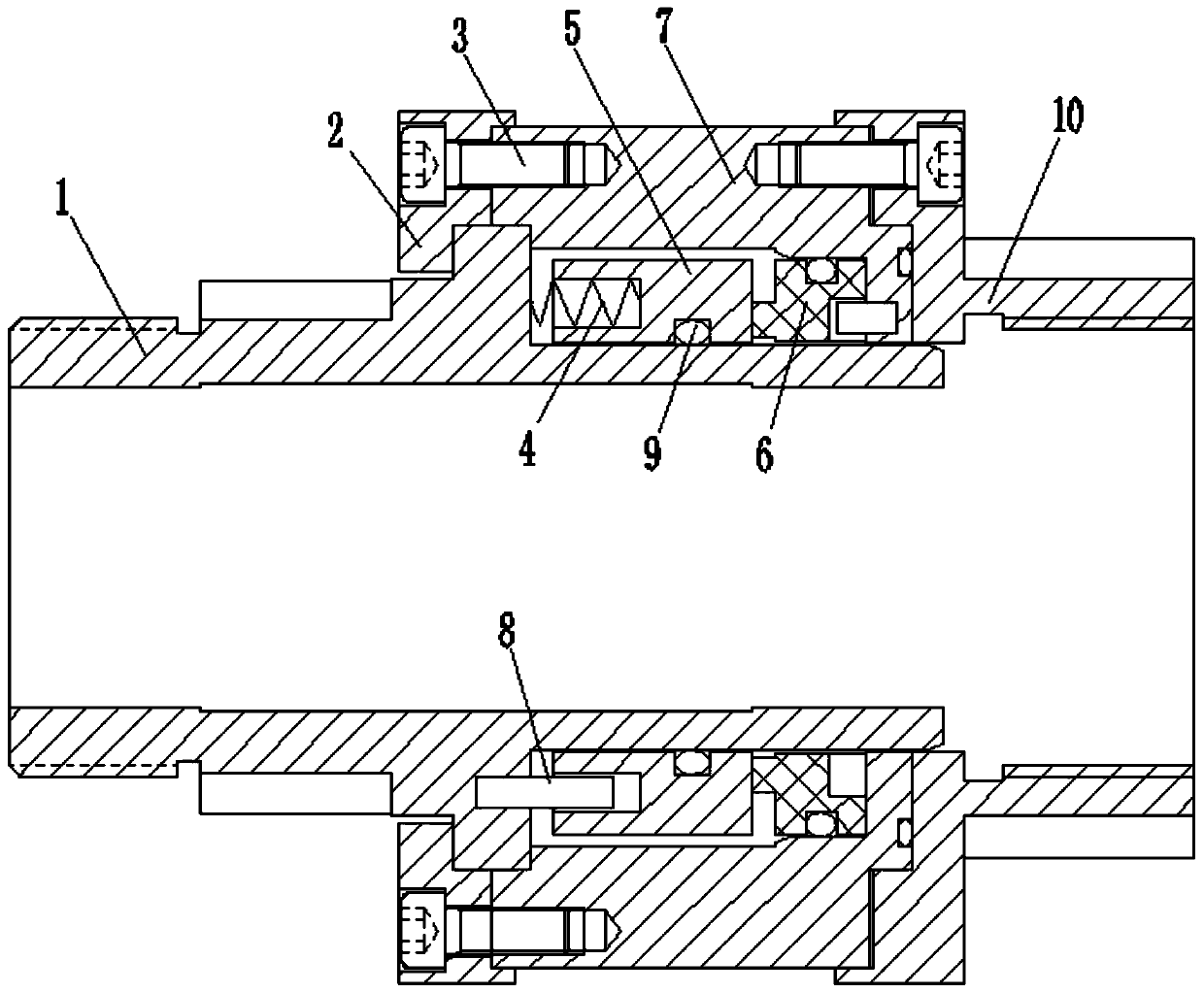

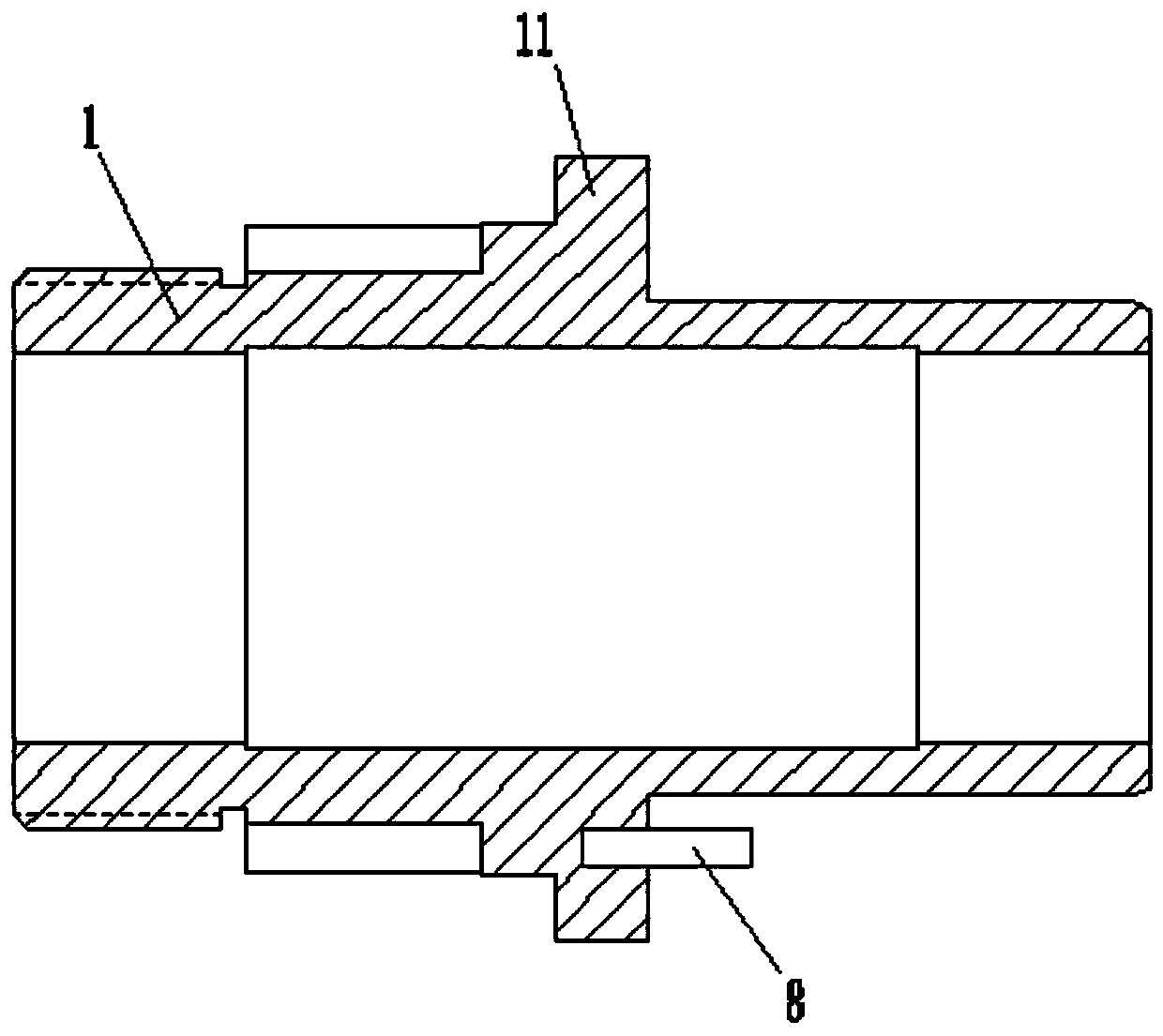

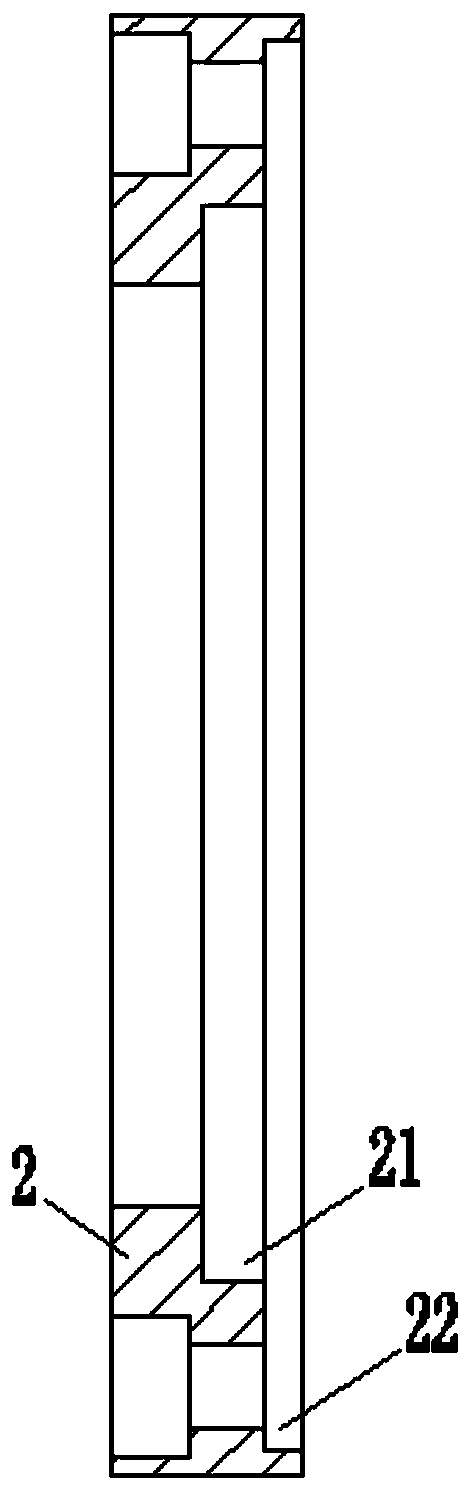

[0025] The structure of the rotary joint is as follows figure 1 As shown, it is composed of a shaft sleeve 1, a gland 2, a moving ring 5, a static ring 6, a static ring seat 7 and a pressure plate 10. The shaft sleeve 1 and the pressing plate 10 are sleeved and installed on the ends of the two pipes respectively. The structure of the shaft sleeve 1 integrally formed of nylon material is as follows: figure 2 As shown, the outer surface of the center is coaxially provided with an annular protrusion as the limiting convex ring 11, and the gland 2 and the static ring seat 7 sleeved on the shaft sleeve 1 are respectively arranged on both sides of the limiting convex ring 11. The structure of pressing plate 10 is as image 3 It is shown that the end facing the static ring seat 7 is sequentially arranged as a stepped ring structure with gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com