Three-plane reference mirror flatness absolute measurement method based on small deflection

An absolute measurement and reference mirror technology, applied in the field of optical inspection, can solve the problems of time-consuming and low surface data sampling rate, and achieve the effect of improving the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

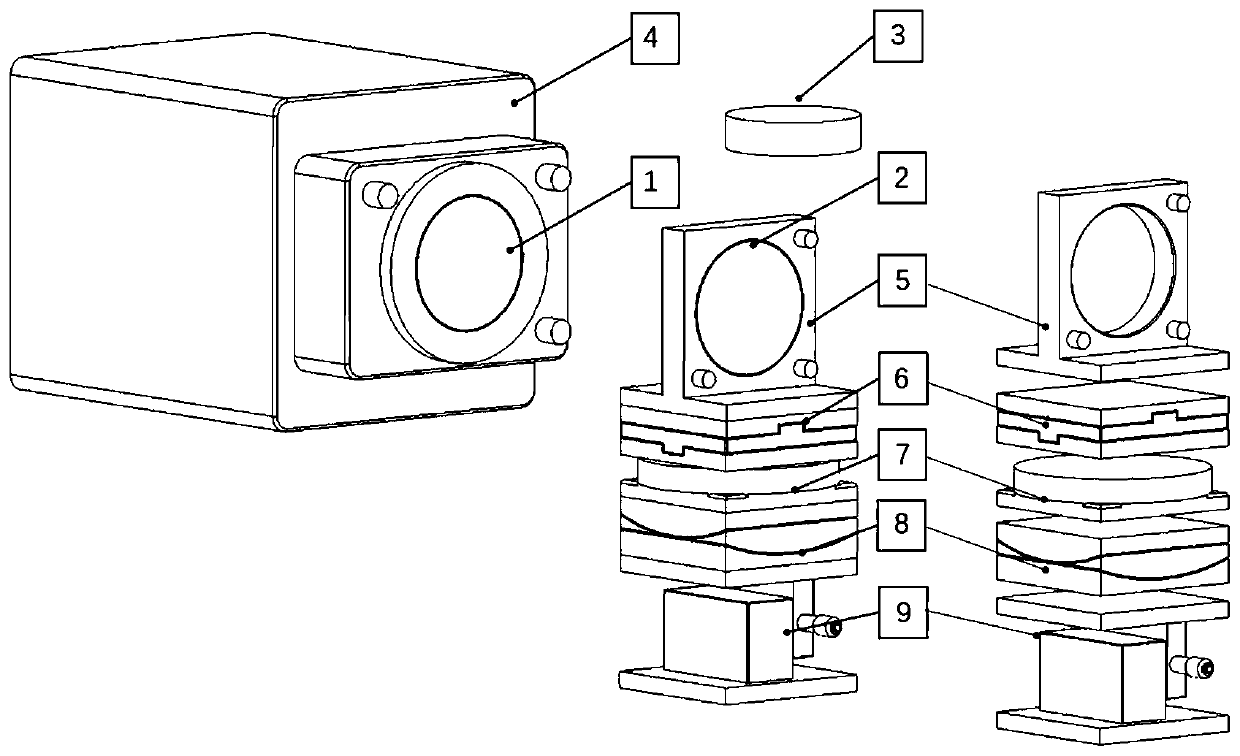

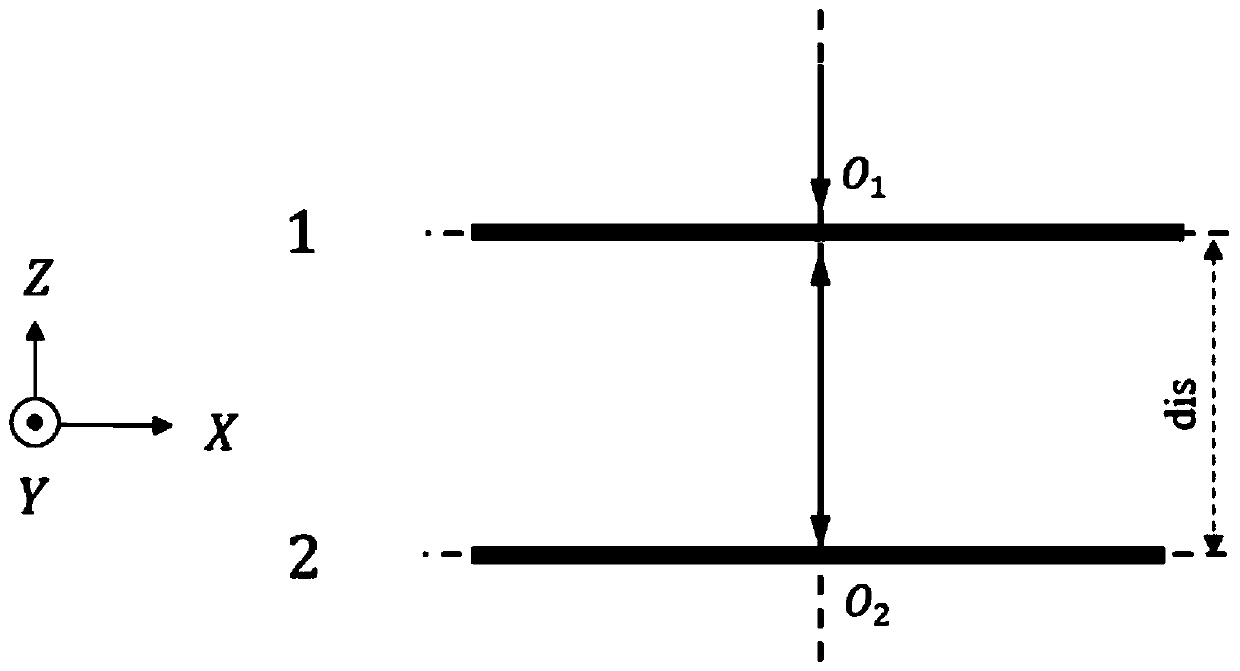

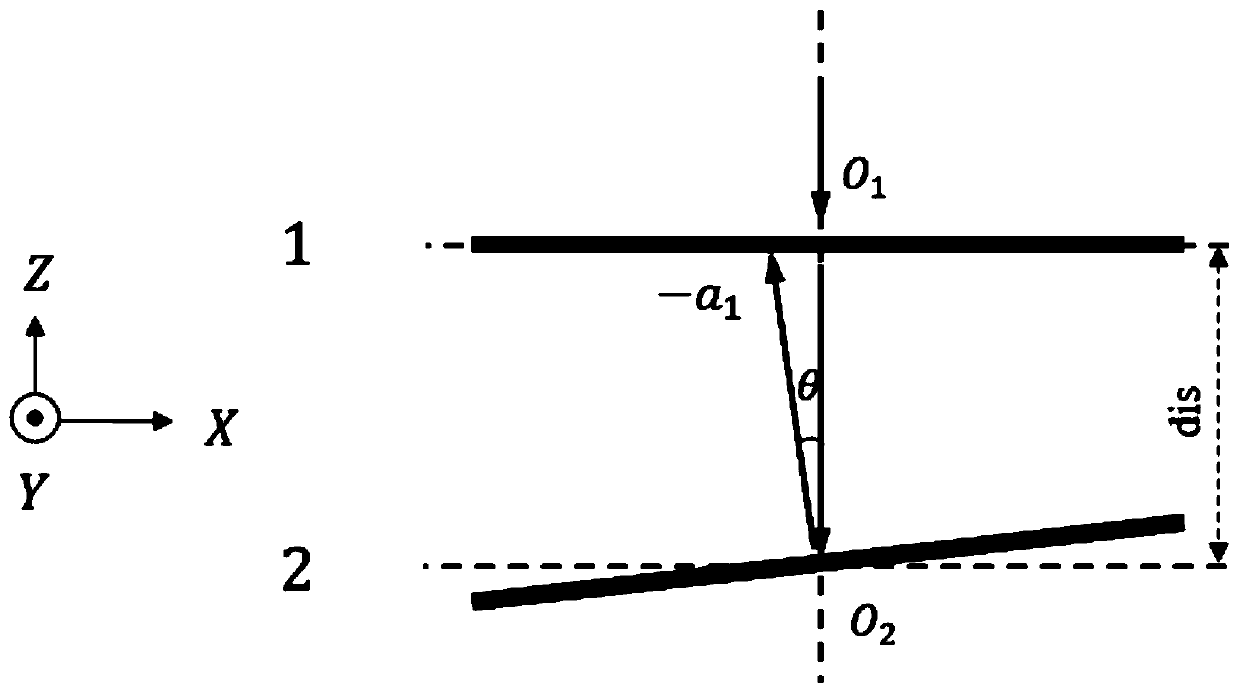

[0051] This embodiment is based on the small deflection three-plane reference mirror flatness absolute measurement method, and the measurement system adopted includes three plane reference mirror A 1, plane reference mirror B 2, plane reference mirror C 3, high Precision Fizeau-type laser interferometer 4, reference mirror fixing frame 5, x-direction and y-direction mobile platform 6, electric control turntable 7, pitch and tilt adjustment platform 8 and lifting platform 9; the lifting platform 9 is at the bottom for Ensure that reference mirrors A1, B2, and C3 are at the same height during measurement. The tilting and pitching adjustment platform 8 prevents from being below the electric control turntable 7, and is used to adjust the axis of the electric control turntable 7 to be perpendicular to the outgoing light wavefront of the laser. The m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap