Precise static balance trimming method for pitch axis of large-size photoelectric theodolite

A photoelectric theodolite and pitch axis technology, which is applied in static/dynamic balance testing, instrument, machine/structural component testing, etc., can solve problems such as time-consuming, difficulty in ensuring trim accuracy, and 3D modeling difficult to meet the needs of engineering practice, etc. Achieve the effect of avoiding motor damage and improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

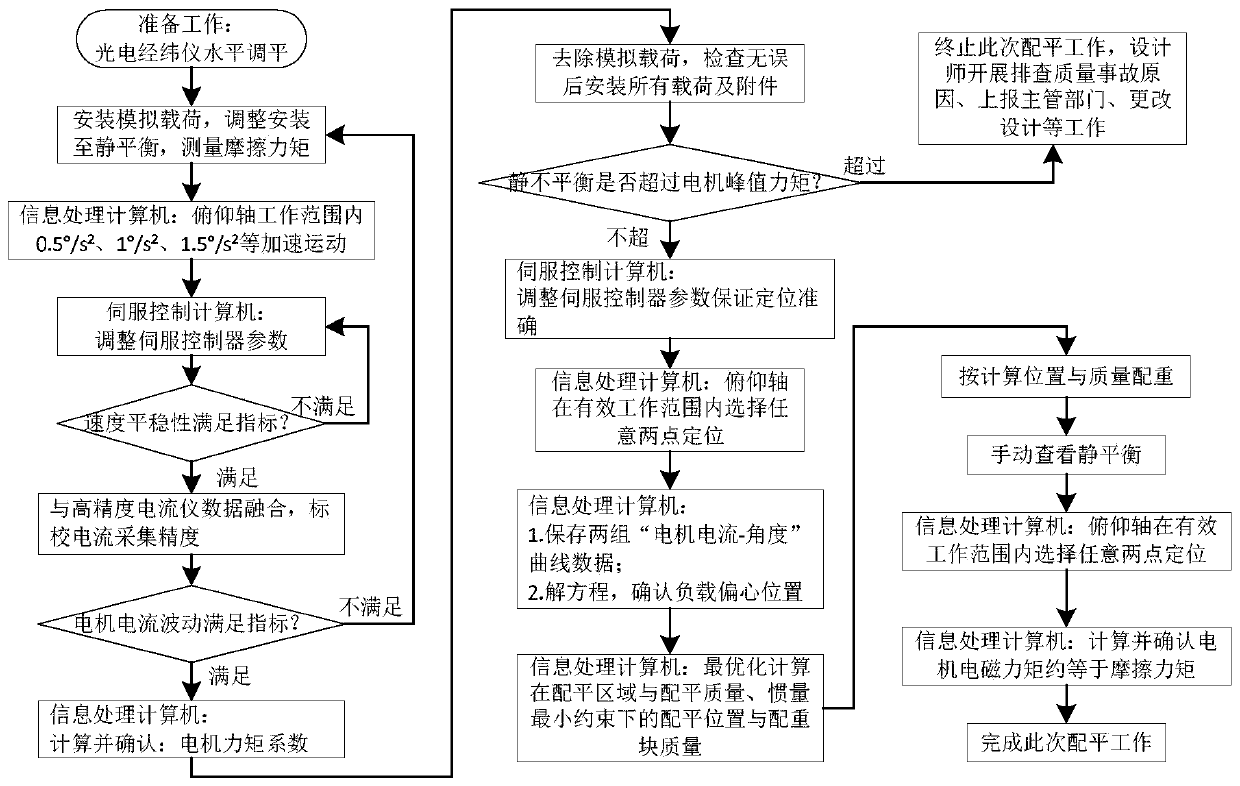

[0047] The present invention will be further described below in conjunction with accompanying drawing.

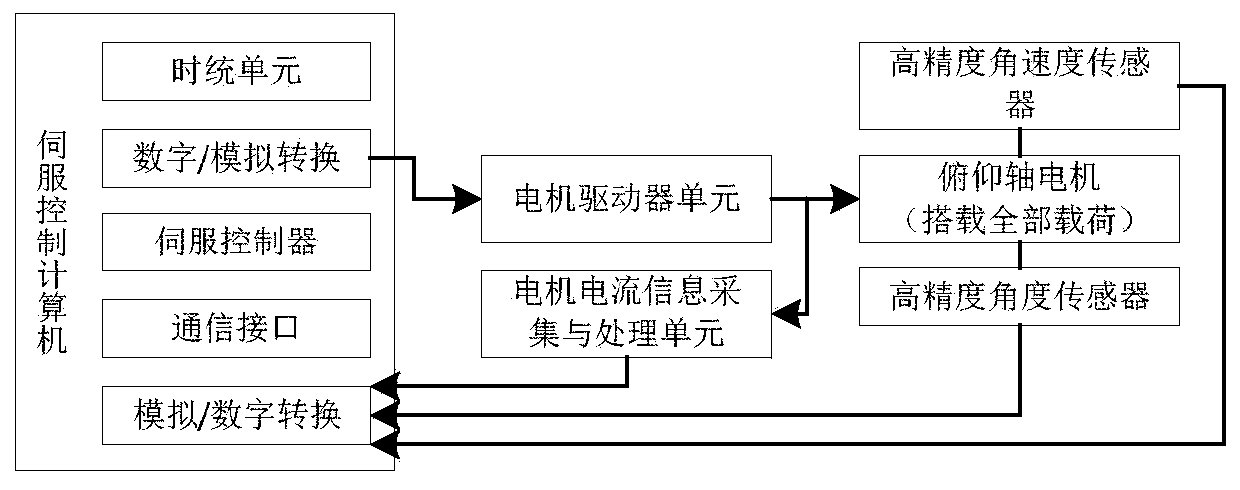

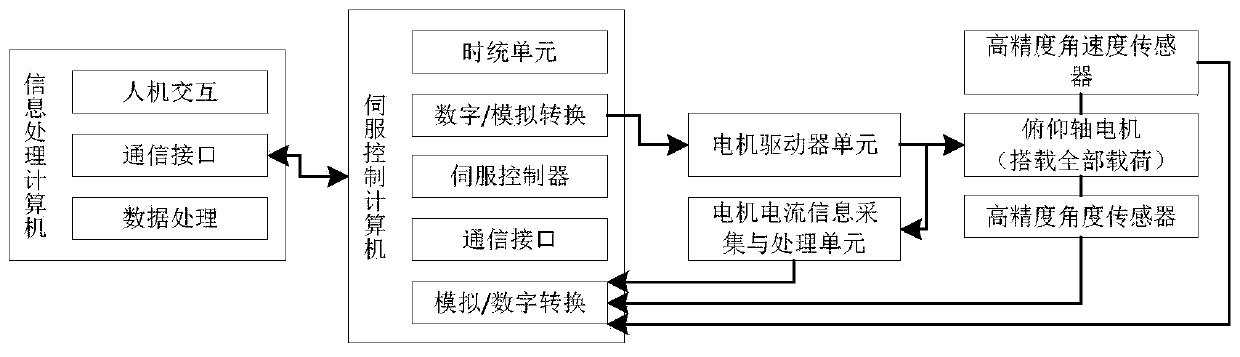

[0048] 1. Composition of photoelectric theodolite pitch axis static balance trim system

[0049] like figure 1 As shown, the existing photoelectric theodolite pitch axis servo control system consists of a pitch shaft system and a bearing (not shown in the figure), a pitch axis motor, a high-precision angle sensor, and a high-precision angular velocity sensor (some photoelectric theodolites are not equipped with a high-precision angular velocity sensor , the angular velocity information is calculated by the angle information of the high-precision angle sensor. This method is also applicable to the static balance trimming of this type of photoelectric theodolite), a motor driver unit, a motor current information acquisition and processing unit, and a servo control computer.

[0050] The pitch axis motor, high-precision angle sensor, and high-precision angular velocity sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com