Drop hammer type steel wire rope impact failure test device and method

A technology of impact damage and test equipment, which is applied in the direction of measuring equipment, application of repeated force/pulsation force to test material strength, instruments, etc., can solve the problem that the impact application condition of the interception steel wire rope has not been reflected, and does not involve the detection of wire rope interception performance and Impact damage analysis and other issues to achieve strong impact intensity and ensure the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

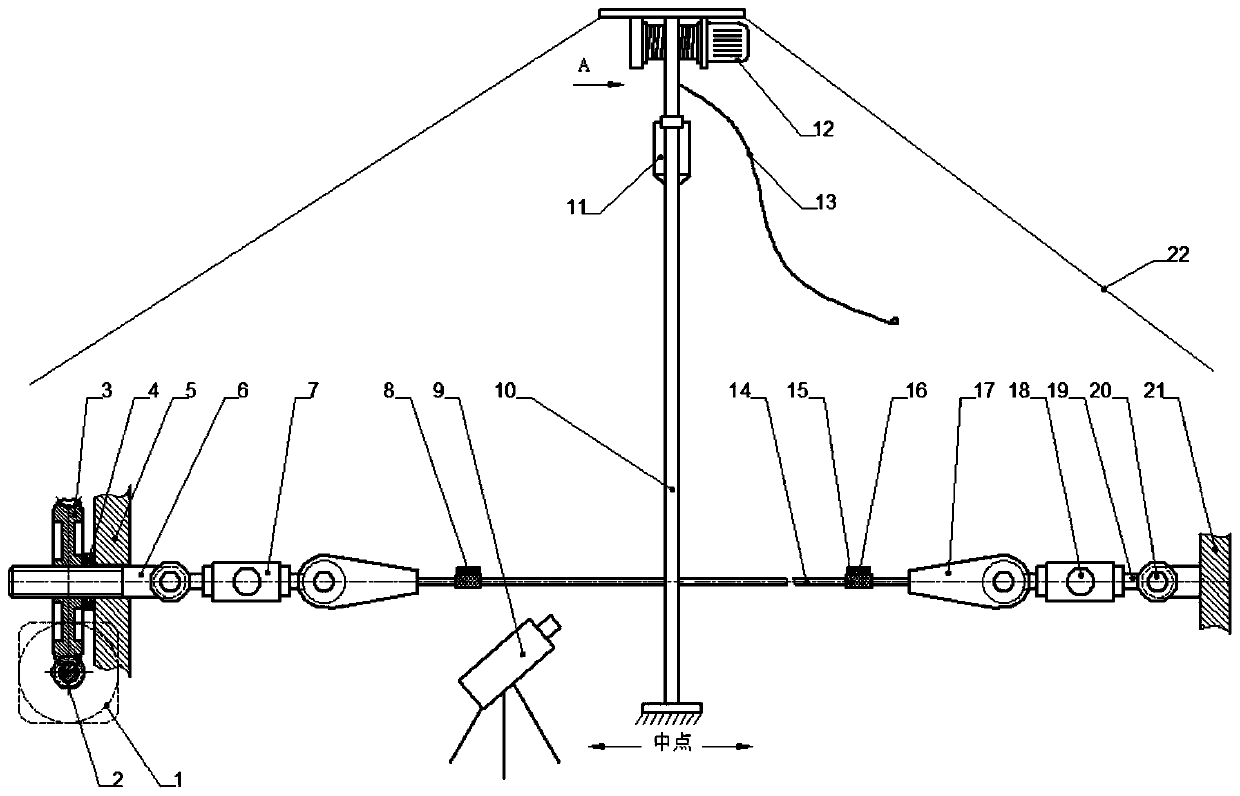

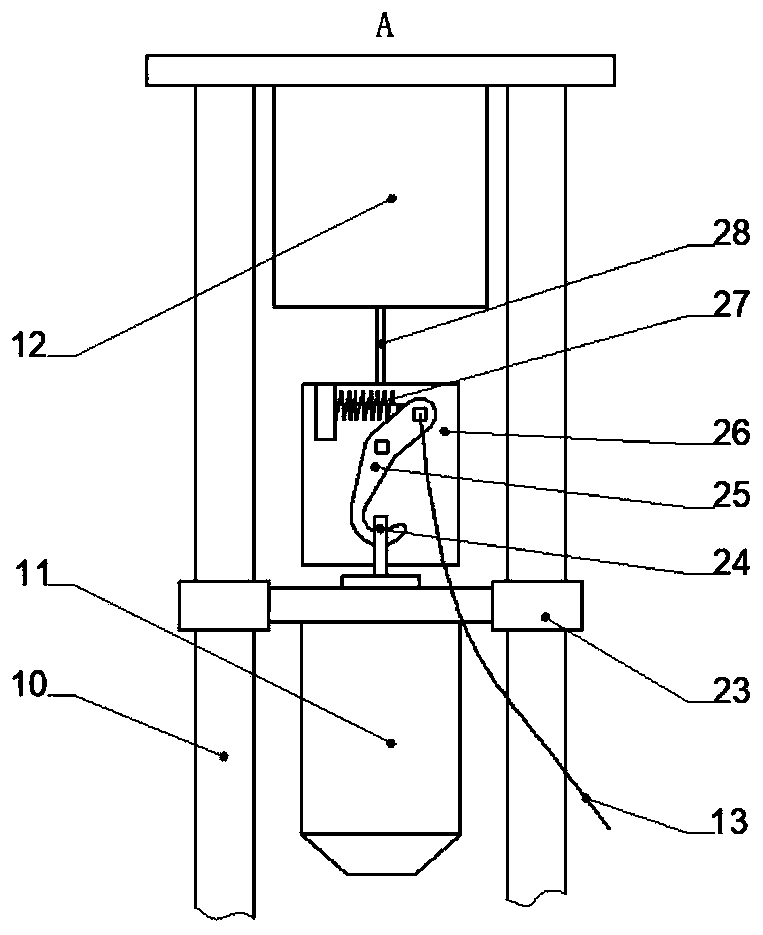

Method used

Image

Examples

Embodiment

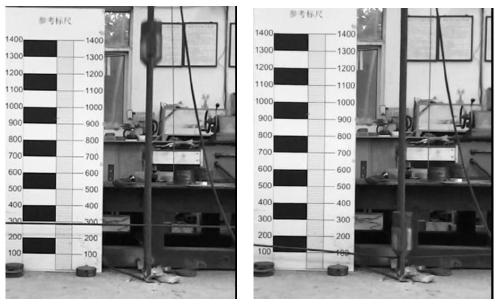

[0032] The content of the analysis in this patent is that the wire rope preload force is 3t, the impact instantaneous speed is 10m / s, and the screenshot of the video of the wire rope falling hammer taken by high-speed camera is as follows: image 3 (midpoint position), the vibration displacement obtained by video tracking processing is as follows Figure 4 , it can be seen that the vibration of the steel wire rope after the impact is a uniform oscillation damping vibration. Draw the wire rope tension signal collected by the tension sensor as Figure 5 , the tension of the steel wire rope has an instantaneous impact peak value, and the loss of the remaining pretension force of the steel wire rope is about 80% of the original. The vibration signal collected by the acceleration sensor is drawn as Image 6 , the peak fluctuations of the positions on both sides due to impact can be obtained.

[0033] The obtained change law of the tension vibration of the steel wire rope after be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com