A kind of sintered NdFeB magnet and its preparation method

A technology of NdFeB and magnets, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of low maximum usable temperature, high production cost of magnets, uneven magnetic field, etc., and achieve low cost, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The first aspect of the present invention discloses a preparation method of a sintered NdFeB magnet, comprising the following steps:

[0029] Prepare n kinds of NdFeB powders, n≥2, the remanence of the NdFeB powders is the same, and the maximum usable temperature is different;

[0030] Establishing a three-dimensional distribution model of the internal temperature resistance of the sintered NdFeB magnet to be prepared, and decomposing the sintered NdFeB magnet to be prepared into micro-magnets with different maximum usable temperatures in three-dimensional space according to the three-dimensional distribution model;

[0031] According to the three-dimensional distribution model, after introducing the NdFeB powder into the three-dimensional space, press molding to obtain a magnetic green body;

[0032] The magnetic green body is sintered and aged to produce a sintered NdFeB magnet with temperature resistance distribution.

[0033] Specifically, the preparation method ro...

Embodiment 1

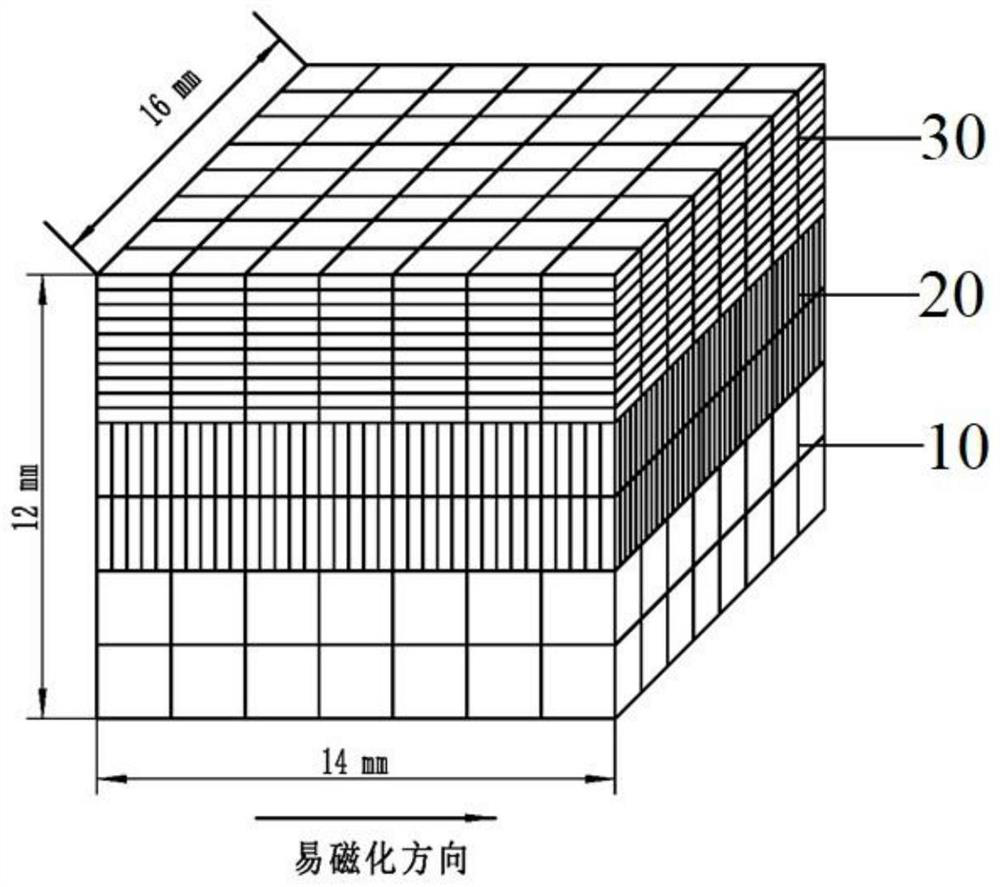

[0044] Prepared in this example is a sintered NdFeB magnet suitable for one-dimensional gradient temperature field and one-dimensional distribution of temperature resistance. The three-dimensional size of the magnet prepared in this example is 12mm×16mm×14mm, and the 14mm side is easy Magnetization direction, the 12mm side is the direction of temperature resistance change.

[0045] Concrete preparation comprises the following steps:

[0046]Prepare NdFeB powders A, B, and C with Br= 12.0 kGs, and the highest usable temperatures are 80°C, 100°C, and 120°C respectively;

[0047] According to the characteristics of the one-dimensional gradient temperature field, a three-dimensional model of the maximum usable temperature distribution of the magnet to be prepared is established, and the magnet to be prepared is decomposed into 6×8×7=336 pieces (the three-dimensional size is 2mm×2mm×2mm) with the highest usable temperature Different micro-magnet models establish the correspondence...

Embodiment 2

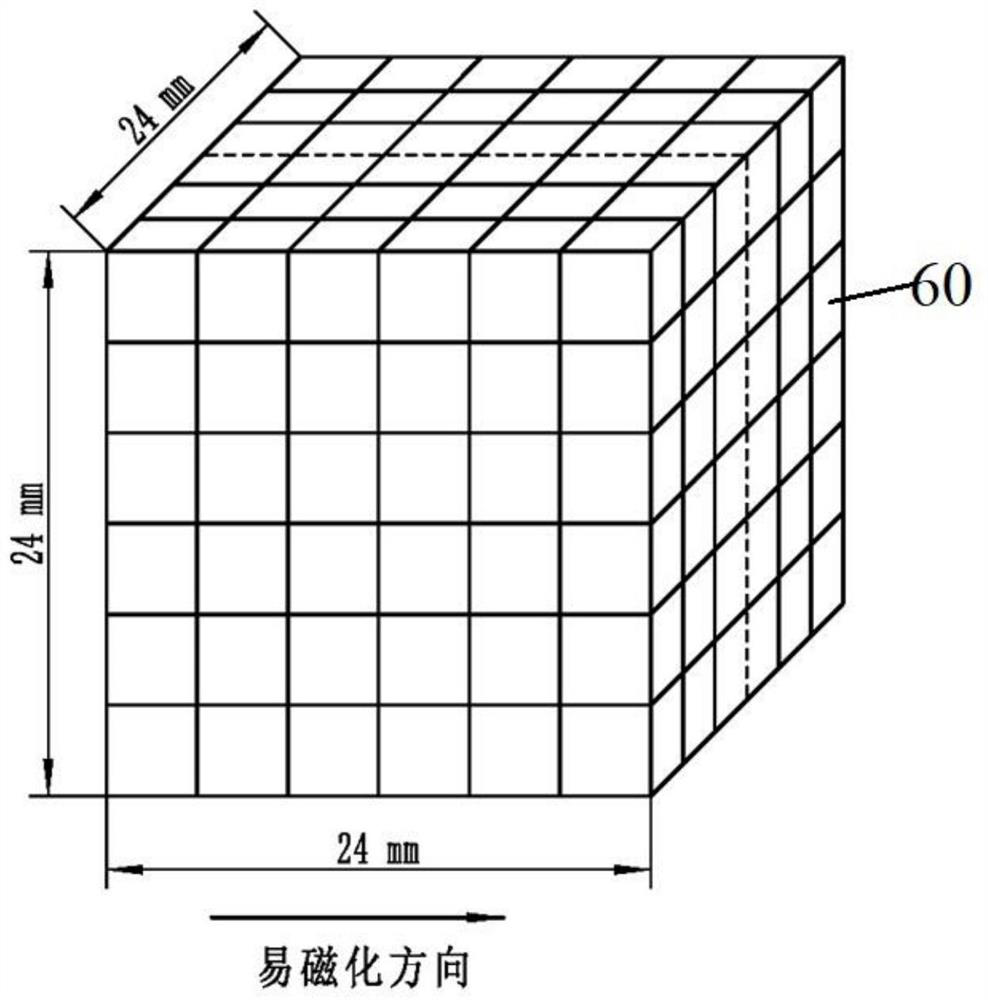

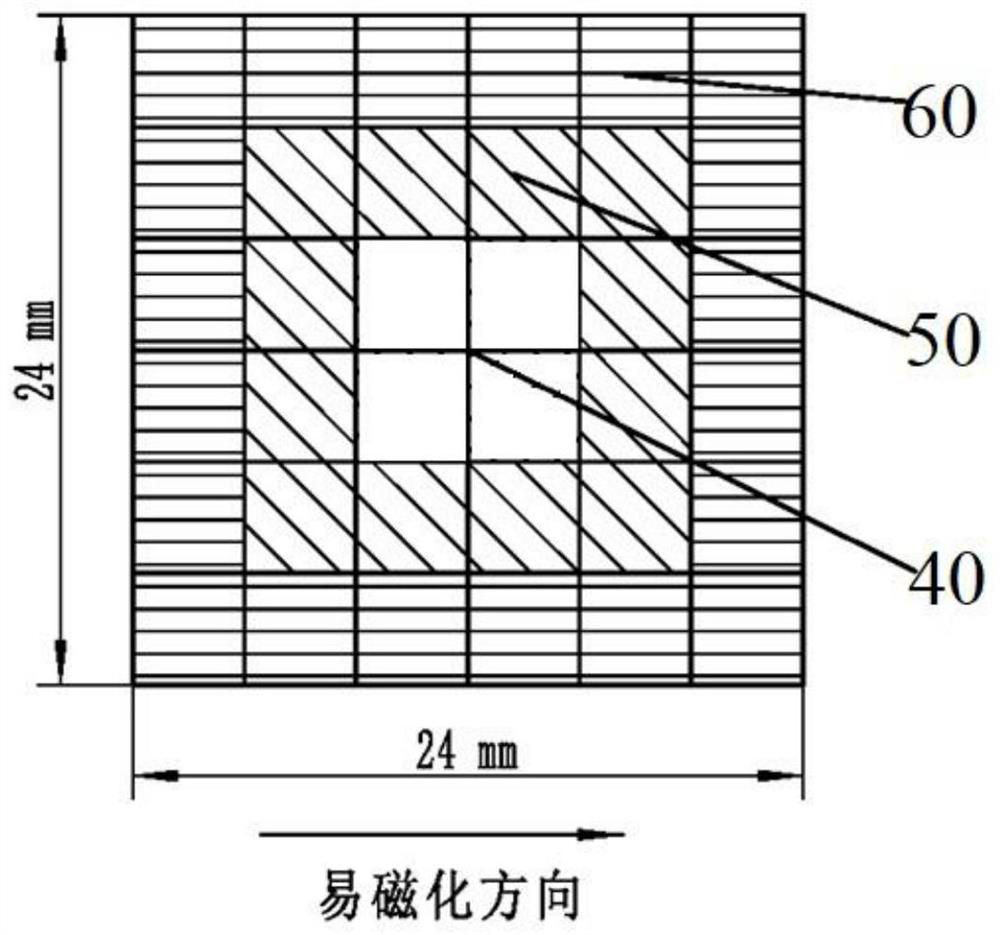

[0057] According to the use environment, when the sintered NdFeB magnet is in the process of injection molding, it will be affected by the high temperature of the injection material, which will lead to a higher external temperature and a lower core temperature, showing the characteristics of "low temperature in the core and high temperature in the periphery". Therefore, In this embodiment, a temperature-resistant distributed magnet suitable for injection molding packaging is produced, and the three-dimensional size in this embodiment is 24mm×24mm×24mm.

[0058] Concrete preparation comprises the following steps:

[0059] Prepare NdFeB powders D, E, and F with Br=13.0kGs, and the highest usable temperatures are 120°C, 150°C, and 180°C respectively;

[0060] According to the characteristics of the temperature field of the magnet in the injection molding process, a three-dimensional model of the temperature resistance distribution of the magnet to be prepared is established, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com