Tool module for textile machines

A tool module and tool technology, applied in textiles and papermaking, knitting, warp knitting, etc., can solve problems such as unfavorable machines, and achieve the effects of improving cooling, reducing heat increase, and increasing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

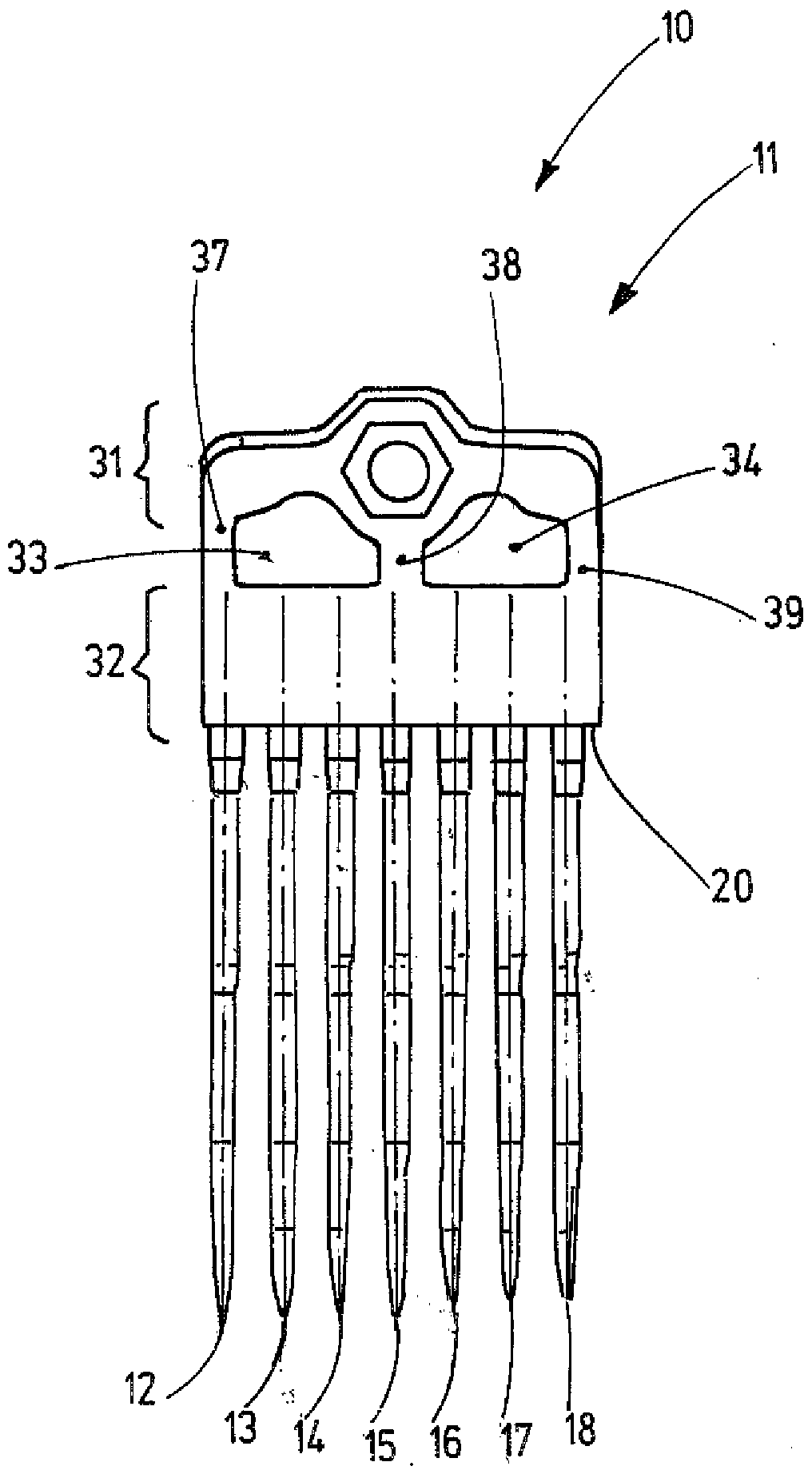

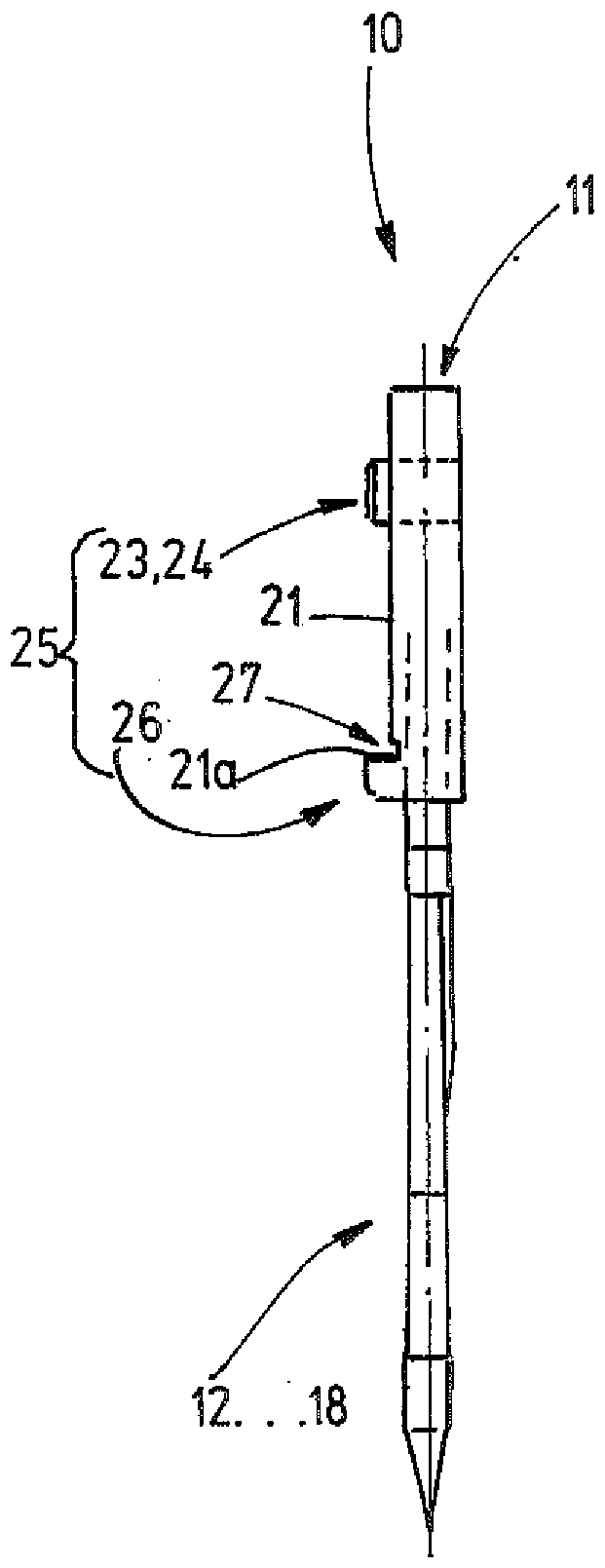

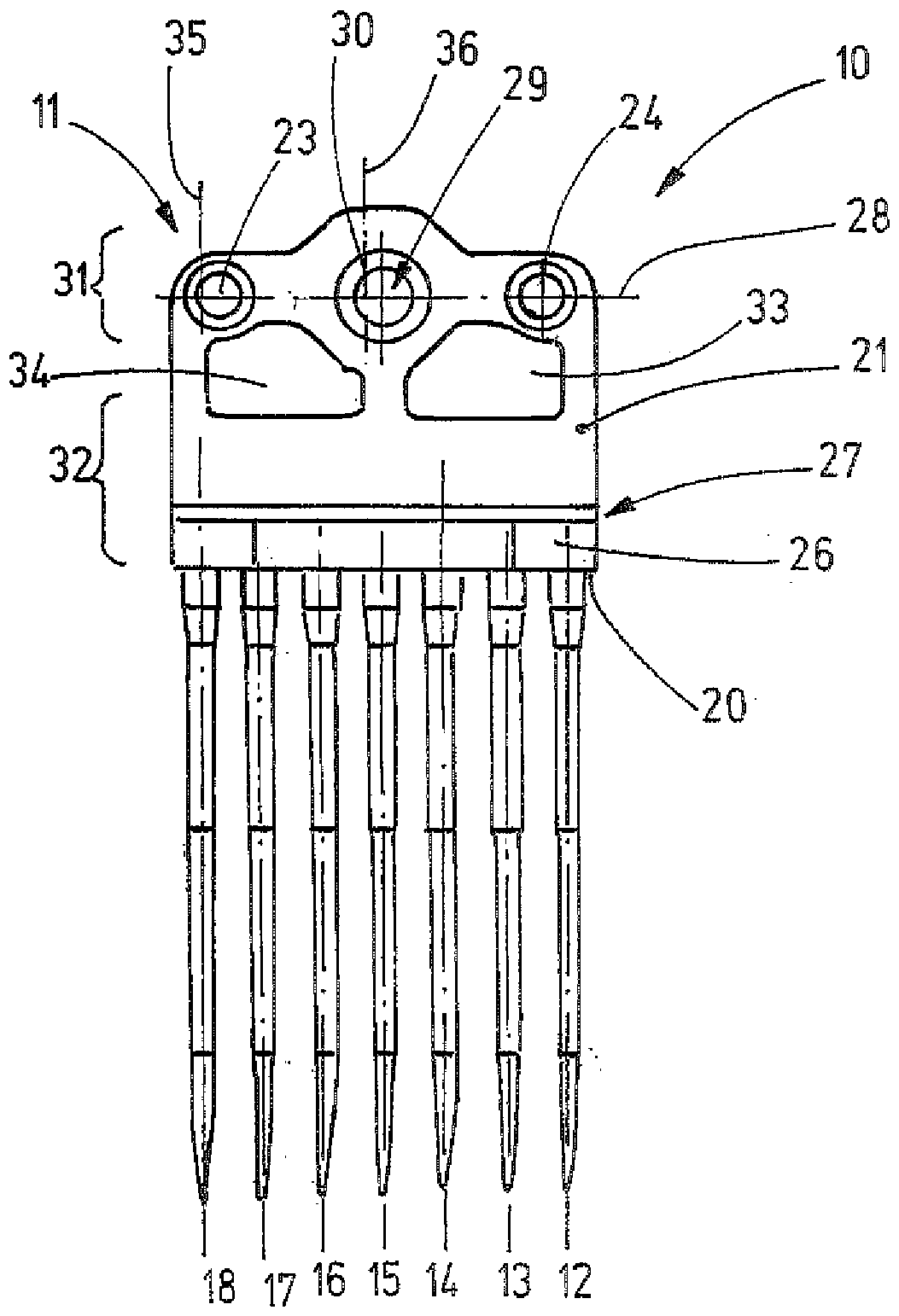

[0023] exist figure 1 In FIG. 1 , a tool module 10 is shown for illustrative purposes only to illustrate features of the invention, comprising a module body 11 and tools 12 - 18 retained at the module body. Tufting needles are exemplarily shown as tools. Similarly, however, other tools such as guide pins, grippers, fingers, knives, etc. may be provided that operate in parallel in synchronization with each other. Independently thereof, the tools 12 - 18 are arranged parallel to one another and are fastened with their respective shank ends at the module body 12 . As an example, 7 tools are shown. However, any other desired number and singular number of tools may be provided at the module body 11 .

[0024] The module body 11 is preferably formed of metal, in particular zinc alloy, zinc aluminum alloy or another metal alloy which melts at a temperature below 1000°C. In particular, the module body 11 may be formed as a die-cast body.

[0025] The module body 11 has the form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com