Methylprednisolone sodium succinate powder for injection and preparation method thereof

A technology for methylprednisolone sodium succinate and injection, which is applied in the field of methylprednisolone sodium succinate powder for injection and its preparation, can solve the problems of long freeze-drying cycle, cumbersome, low production efficiency, etc., and achieve quality improvement and Stability, reduced freeze-drying time, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

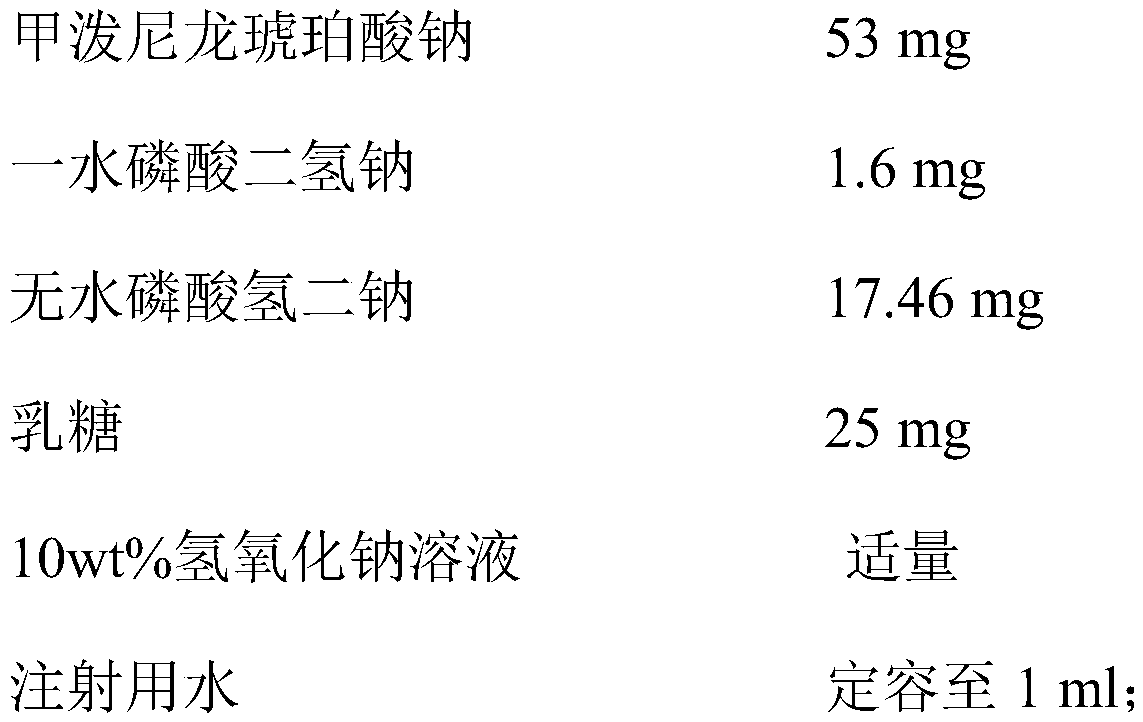

[0058] The specification of the methylprednisolone sodium succinate freeze-dried powder for injection provided in this example is 40 mg / bottle, and its raw and auxiliary material formula is composed as follows:

[0059]

[0060] Its preparation method is as follows:

[0061] (1) Weigh 5.3g methylprednisolone sodium succinate, 0.16g sodium dihydrogen phosphate monohydrate, 1.746g anhydrous disodium hydrogen phosphate and 2.5g lactose, dissolve with 50ml water for injection in a 10°C water bath with magnetic stirring, stir The speed is 280rpm. After clarification, the pH is adjusted to 7.6 with 10% sodium hydroxide solution, and the volume is adjusted to 100ml with water for injection.

[0062] (2) Filter the solution obtained in step (1) successively through 0.45 μm and 0.22 μm microporous membranes, then divide into vials, 1 ml in each bottle, and half stopper.

[0063] (3) The subpackaged solution in step (2) is freeze-dried according to the freeze-drying curve (see Table...

Embodiment 2

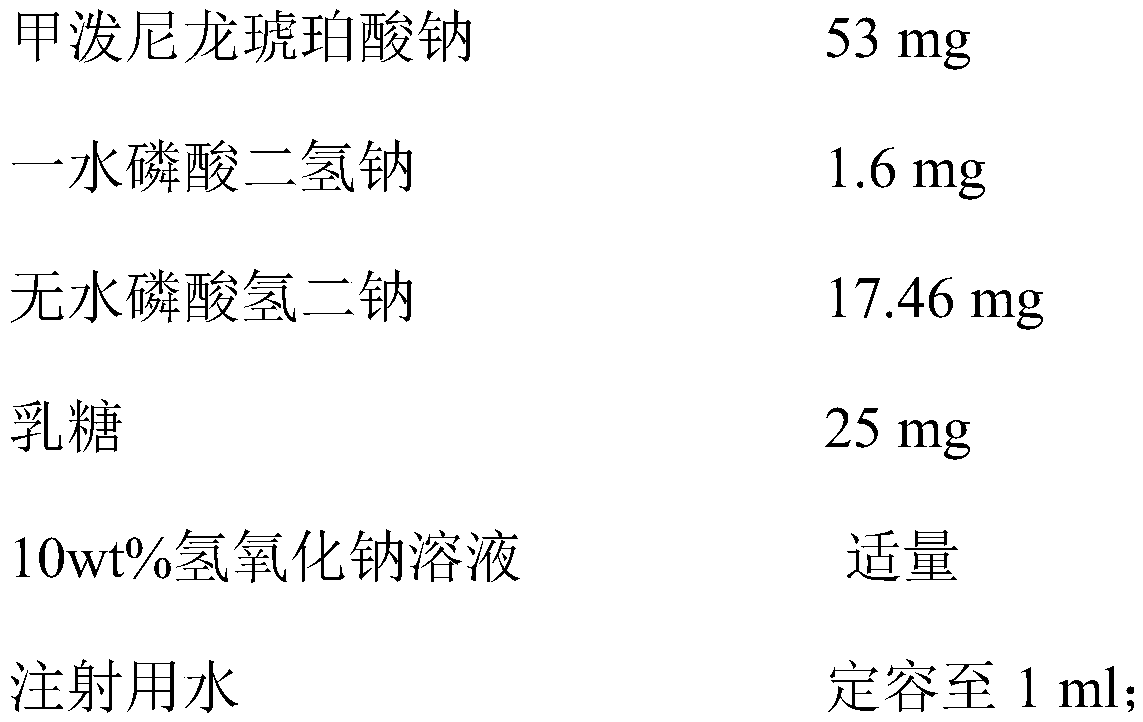

[0065] The specification of the methylprednisolone sodium succinate freeze-dried powder for injection provided in this example is 40 mg / bottle, and its raw and auxiliary material formula is composed as follows:

[0066]

[0067]

[0068] Its preparation method is as follows:

[0069] (1) Weigh 5.3 g of methylprednisolone sodium succinate, 0.16 g of sodium dihydrogen phosphate monohydrate, 1.746 g of anhydrous disodium hydrogen phosphate and 2.5 g of lactose, and dissolve them with 50 ml of water for injection in a 40°C water bath with magnetic stirring, stirring The speed is 280rpm. After clarification, the pH is adjusted to 7.6 with 10% sodium hydroxide solution, and the volume is adjusted to 100ml with water for injection.

[0070] (2) Filter the solution obtained in step (1) successively through 0.45 μm and 0.22 μm microporous membranes, then divide into vials, 1 ml in each bottle, and half stopper.

[0071] (3) The subpackaged solution in step (2) is freeze-dried ac...

Embodiment 3

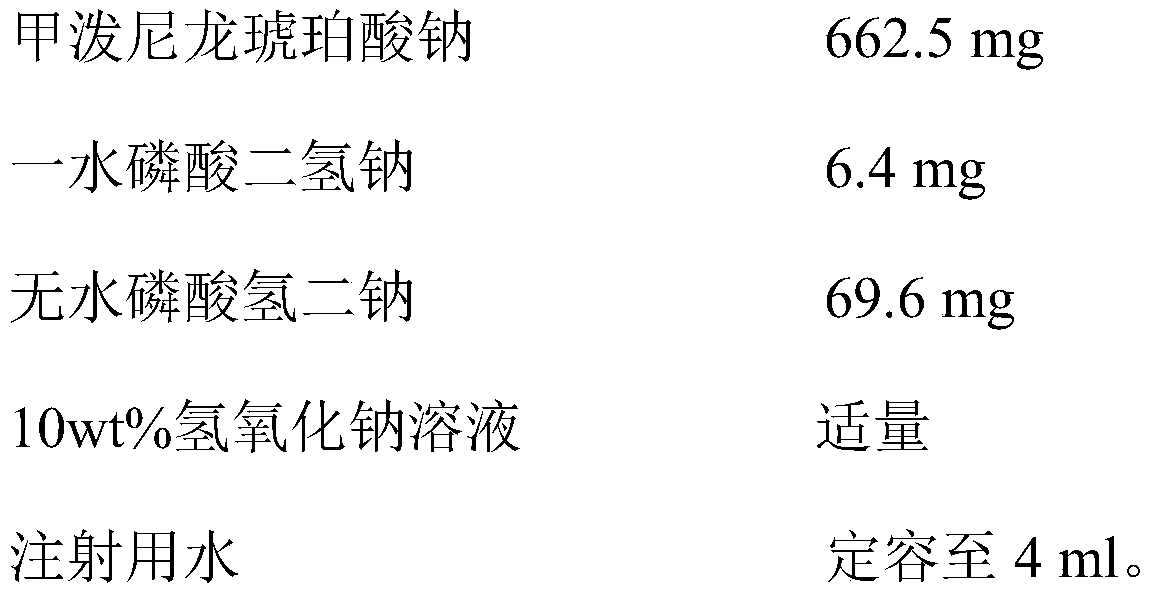

[0073] The specification of the methylprednisolone sodium succinate freeze-dried powder for injection provided in this example is 500 mg / bottle, and its raw and auxiliary material formula is composed as follows:

[0074]

[0075] Its preparation method is as follows:

[0076] (1) Weigh 16.56g of methylprednisolone sodium succinate, 0.16g of sodium dihydrogen phosphate monohydrate, and 1.74g of anhydrous disodium hydrogen phosphate, and dissolve them with 60ml of water for injection with magnetic stirring in a water bath at 10°C at a stirring speed of 280rpm. Finally, adjust the pH to 7.6 with 10% sodium hydroxide solution, and dilute to 100 ml with water for injection.

[0077] (2) Filter the solution obtained in step (1) successively through 0.45 μm and 0.22 μm microporous membranes, and then divide into vials, 4 ml in each bottle, and half stopper.

[0078] (3) The subpackaged solution in step (2) is freeze-dried according to the freeze-drying curve (see Table 1), plugge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com