Hydraulic control circuit and method used for injection machine and capable of realizing high-speed and high-precision injection

A control circuit and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of limited flow rate of a single plate servo valve, poor return accuracy of the circuit, high response requirements, etc., to achieve improved brake response, fast injection response, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the invention is not limited to these embodiments.

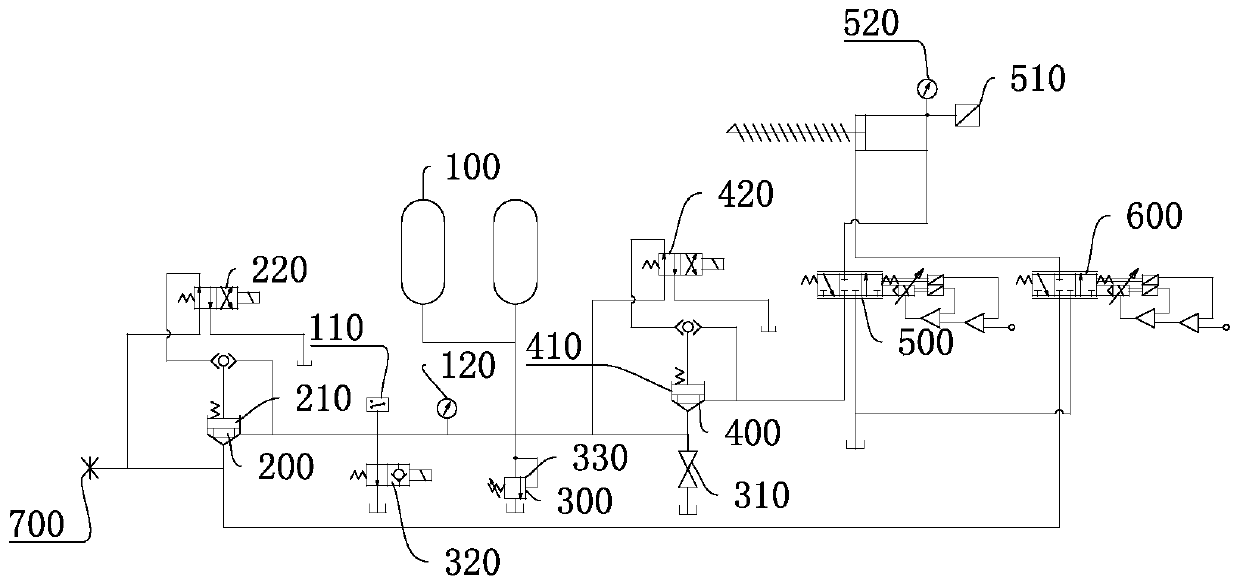

[0021] Such as figure 1 As shown, a high-speed and high-precision injection molding machine hydraulic control circuit is characterized in that it includes: an accumulator 100, a liquid filling control valve group 200, a pressure relief valve group 300, a liquid discharge control valve group 400, and a control valve for the injection molding machine. The first servo valve 500 for the injection cavity and the second servo valve 600 for controlling the ejection cavity of the injection molding machine, and the pressure relief valve group 300 are used to release the pressure of the accumulator during the working process and after it stops working to prevent its pressure from being too high When a dangerous event occurs, the filling con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com