Leather grinding and dust-removing equipment

A kind of dust removal equipment and leather technology, which is applied in the field of leather processing, can solve the problems of no dust removal function, uneven skin grinding, and easy falling of debris on the surface of leather, etc., to achieve low manufacturing cost, improve grinding quality, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

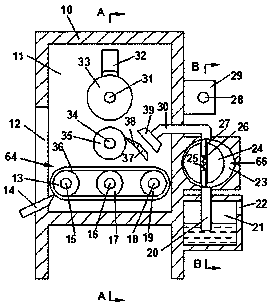

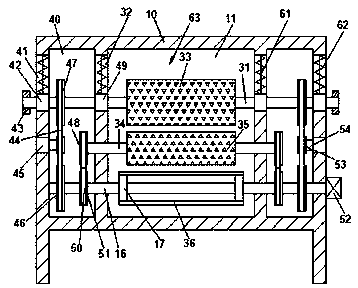

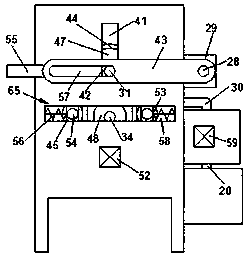

[0016] Combine below Figure 1-4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] refer to Figure 1-4 , according to an embodiment of the present invention, a kind of leather grinding and dedusting equipment includes a body 10, a working chamber 11 is arranged in the body 10, and a transmission chamber 40 is arranged symmetrically on the front and rear sides of the working chamber 11, and the transmission chamber Between 40 and the working chamber 11, there is a guide groove 1 32 communicating with each other, and the transmission chamber 40 is located on the side wall opposite to the guide groove 1 32, and a guide groove 2 communicating with the outside of the body 10 is opened. 41. The working chamber 11 is provided with a grinding device 63 for smoothing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap