Concrete pouring method for large-slope inclined plane

A concrete and large-slope technology, which is applied in the construction, building structure, construction material processing and other directions, can solve the problems of insufficient compaction treatment, affecting the quality of concrete pouring on large-slope slopes, uneven concrete compaction, etc., to ensure the degree of compaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

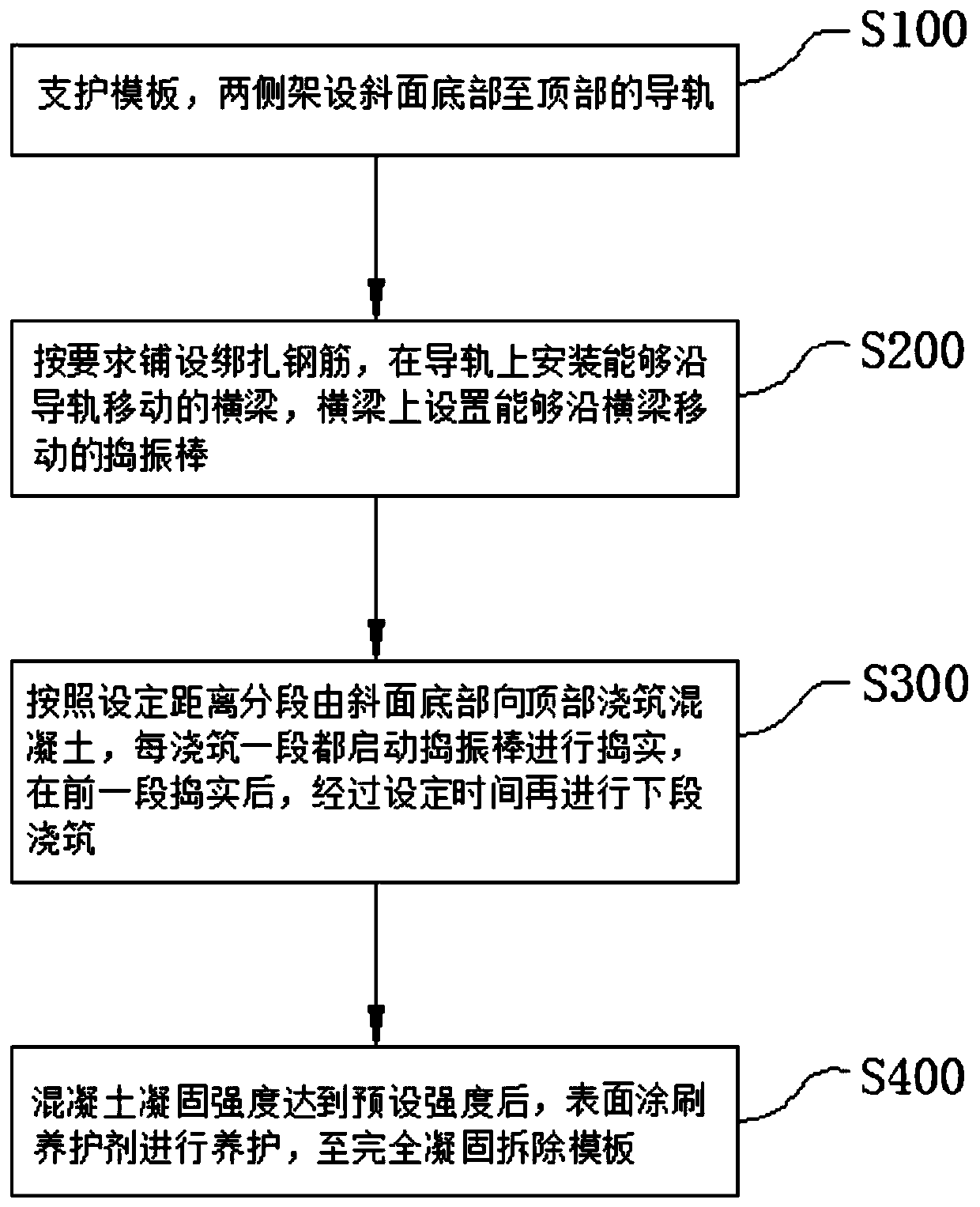

[0047] Such as figure 1 The flow process of the optional embodiment of the concrete pouring method of the shown large-slope slope of the present invention includes the following steps:

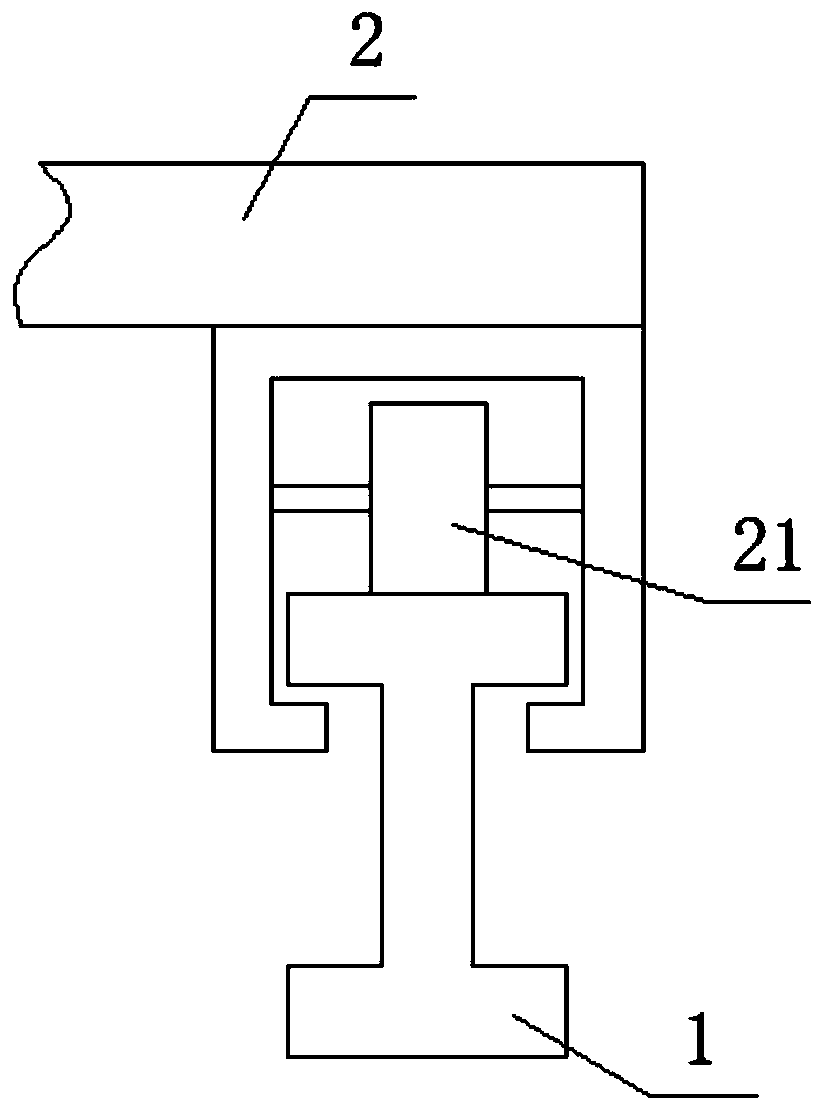

[0048] S100: supporting formwork, erecting parallel guide rails from the bottom to the top of the slope on both sides; figure 2 As shown, the guide rail 1 can be made of I-beam;

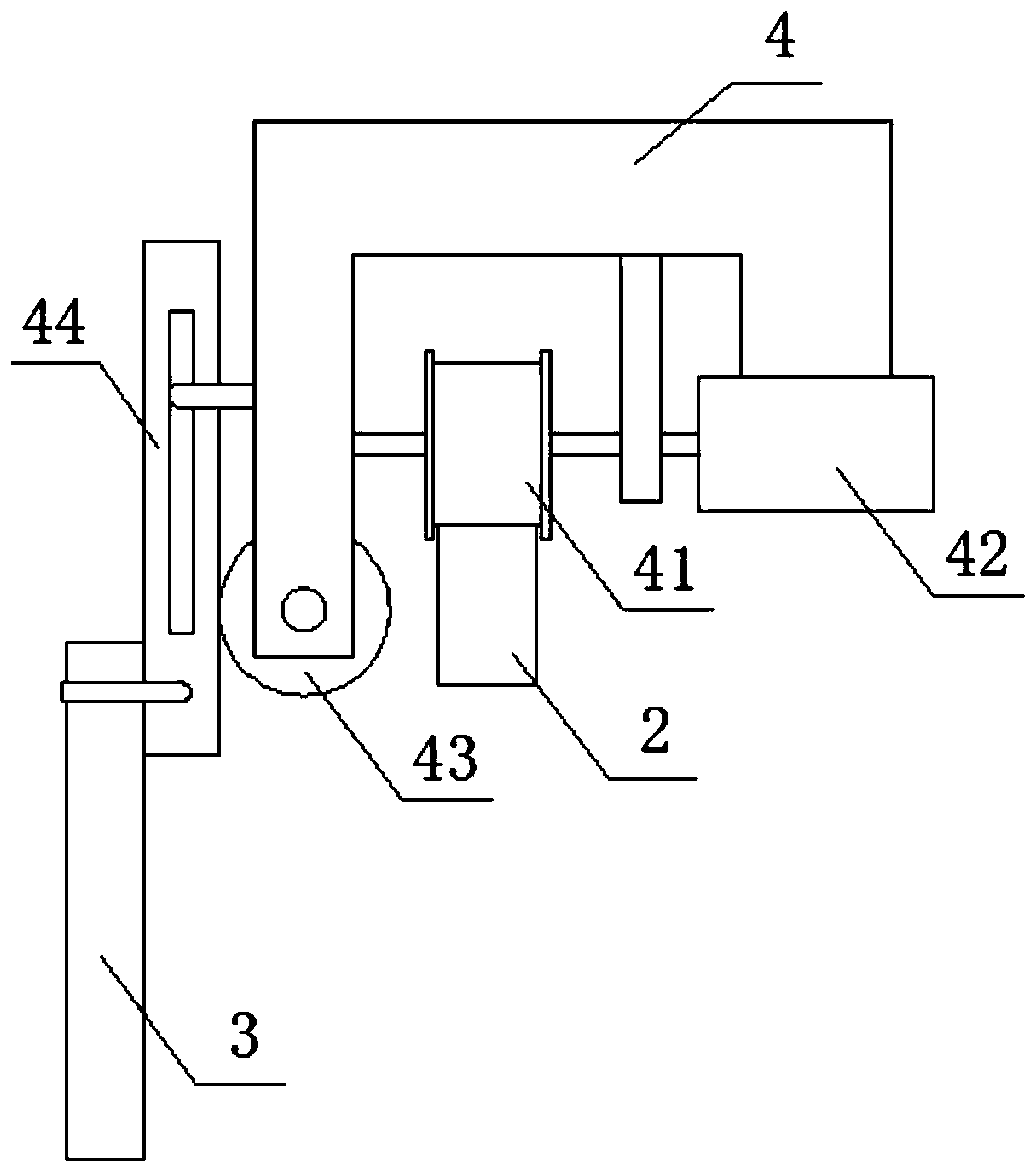

[0049] S200: Lay binding steel bars as required, such as figure 2 As shown, a crossbeam 2 capable of moving along the guide rail 1 is installed on the guide rail 1, and the crossbeam 2 is in contact with the upper end surface of the guide rail 1 with rollers 21; image 3 The vehicle frame 4 that can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com