A Microjet Method for Controlling Flow Separation of Suction Surface of Compressor/Fan Stator Blades

A fan stator and flow separation technology, applied in the direction of machines/engines, blade support components, pump control, etc., can solve problems such as weak flow control on the suction surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

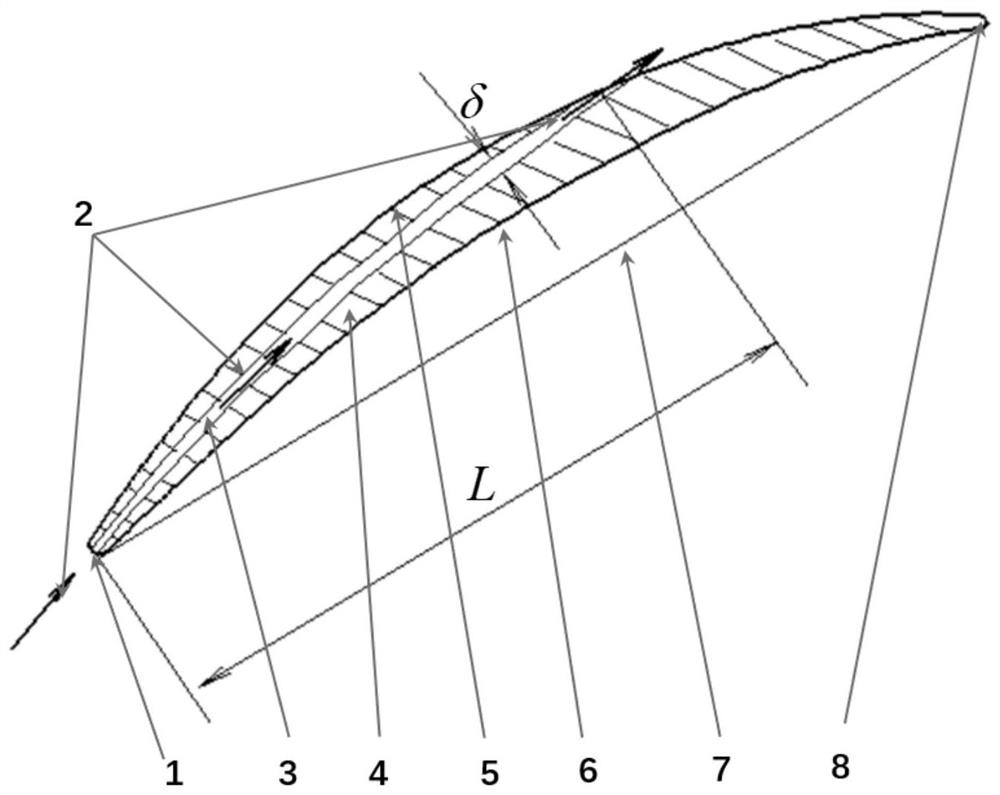

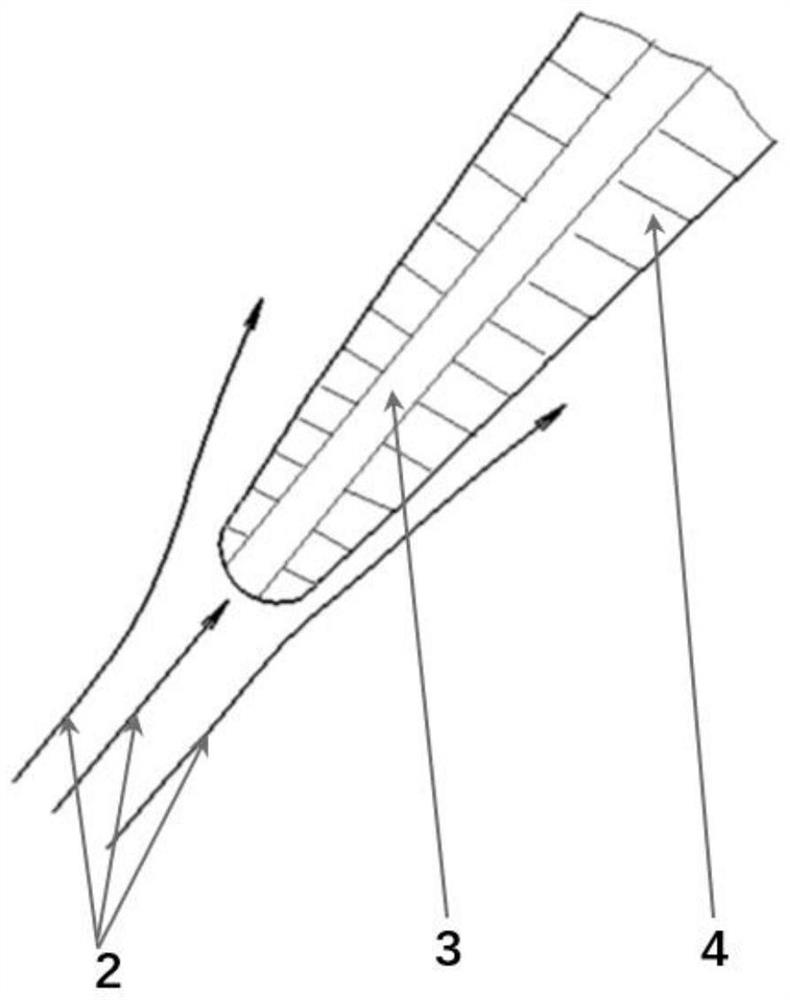

[0016] following by figure 1 The implementation method of the present invention using velocity impulse to form micro-jet control compressor stator suction surface boundary layer is illustrated.

[0017] Axial flow compressor / fan stator blades are formed by stacking several airfoils along the radial direction according to a certain stacking rule, using the airfoil as the skeleton and covering the skeleton with a spline surface. Therefore, the airfoil is the basic element of the blade, and the aerodynamic performance of the blade depends on the airfoil. The present invention is characterized in that: the compressor / fan stator blades are hollow, and the hollow blades are composed of slotted blade profiles, that is, blade profiles (4). One end of the airfoil slit (3) opened on the airfoil (4) is located at the leading edge (1) of the airfoil; the other end is located at the position where the airfoil suction surface (5) needs to be blown off of the boundary layer. When the airfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com