An automatic connection device for oil and gas pipelines for automatic fixtures of machine tools

An automatic connection, oil and gas pipe technology, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of chaotic distribution of driving pipelines of automatic fixtures, affecting the working performance of machine tools, hidden safety hazards, etc., to reduce the cost of transformation and The risk of failure, the appearance arrangement is clean and tidy, and the effect of avoiding damage and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

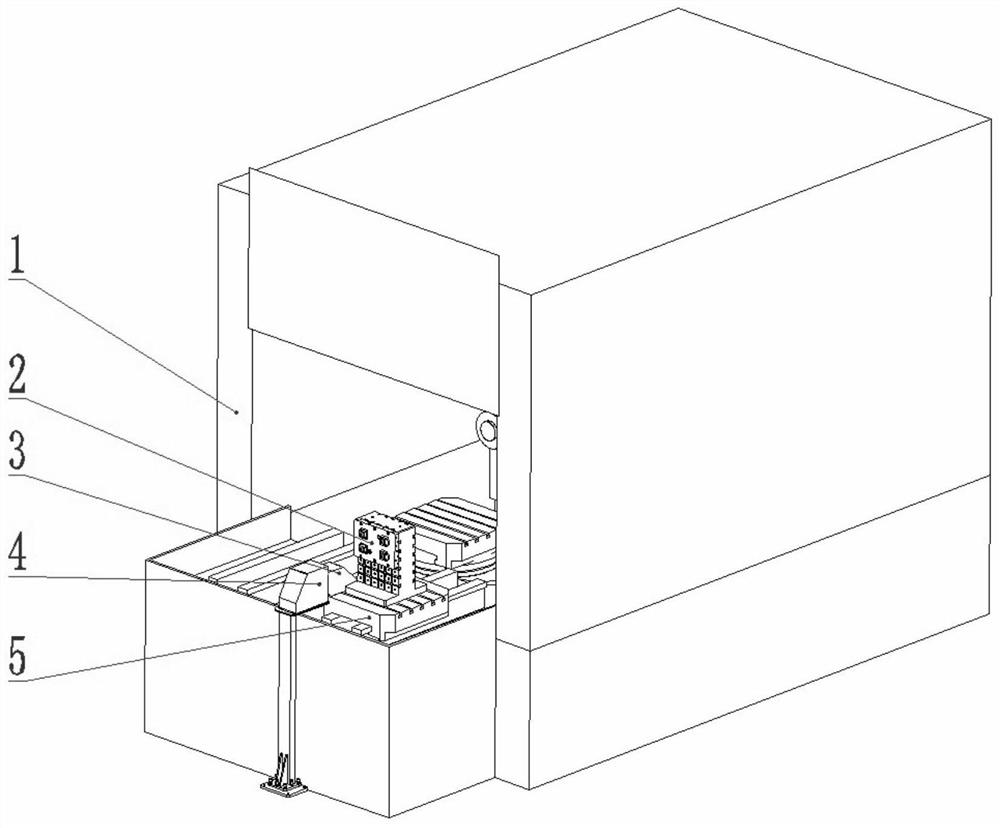

[0025] Such as figure 1 As shown, the present invention is used for the automatic connection of the oil and gas pipelines of the automatic fixture 2 of the machine tool. In this embodiment, the machine tool 1 is a four-axis horizontal machining center with double exchange tables, and the running slideway of the machine tool 1 is provided with A workbench 5, the automatic fixture 2 of the machine tool is set at the center of the workbench 5. The machine tool 1 is a technology known in the art.

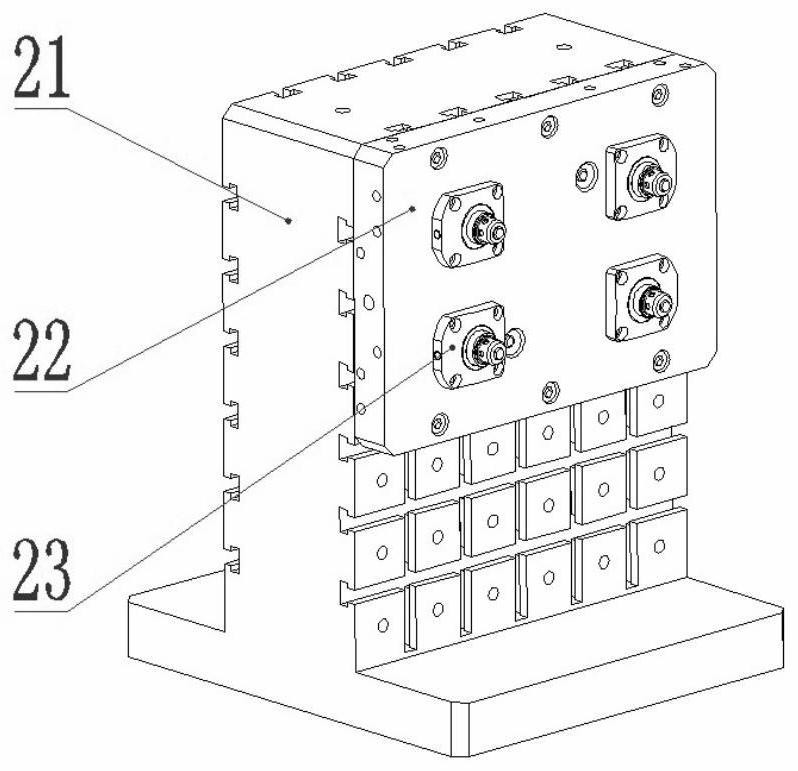

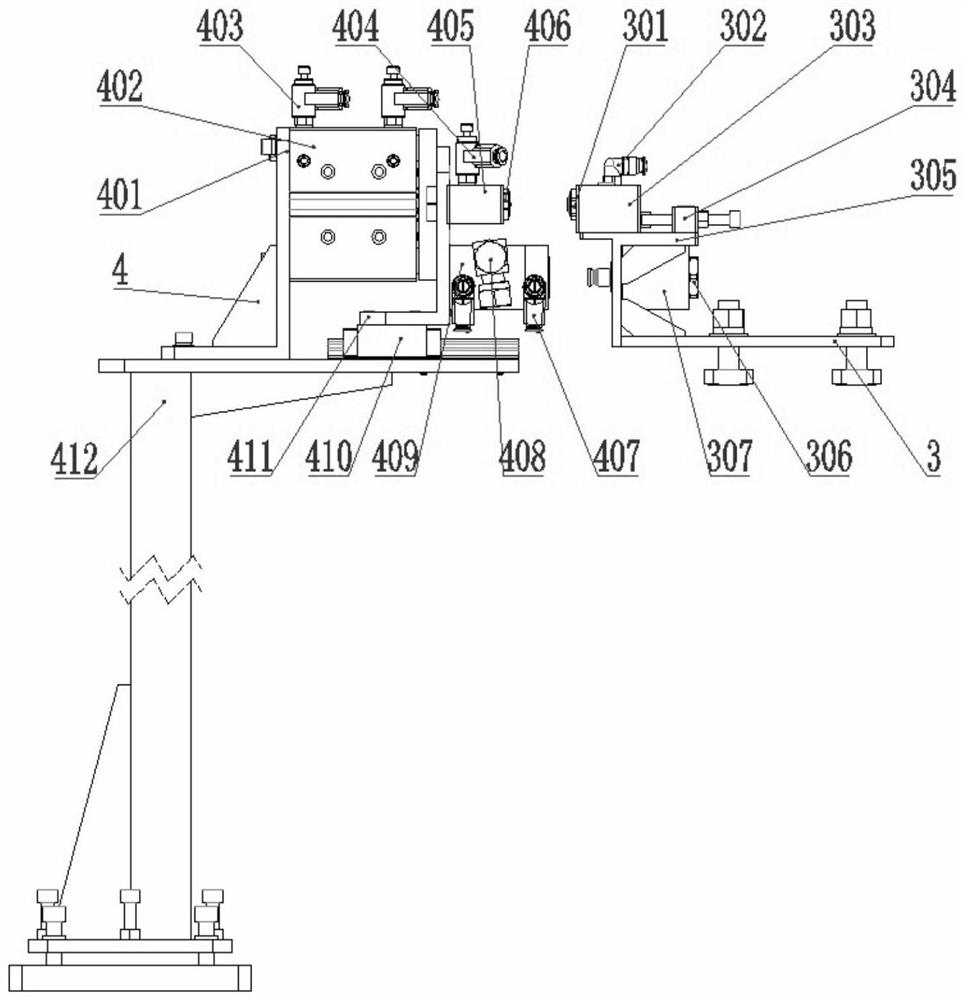

[0026] Such as Figure 1~4 As shown, the present invention includes an internal quick-insert assembly 3 and an external quick-insert assembly 4, wherein the internal quick-insert assembly 3 is fixed on the worktable 5, and the quick-insert direction is parallel to the moving direction of the workbench 5, and the external quick-insert assembly The assembly 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com