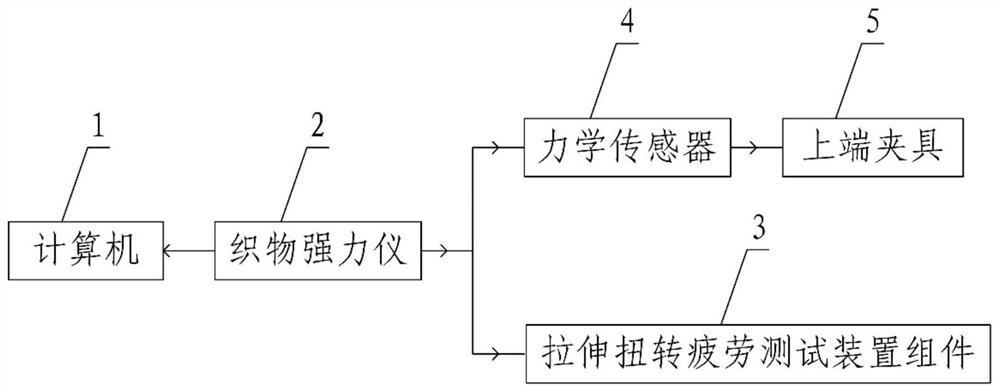

Artificial anterior cruciate ligament tensile torsion composite load fatigue simulation device and its test method

A technology of anterior cruciate ligament and composite load, which is applied in the field of biomechanical property testing devices for biomedical textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example records a fatigue simulation test method of artificial anterior cruciate ligament tensile torsion combined load, the specific test steps are as follows:

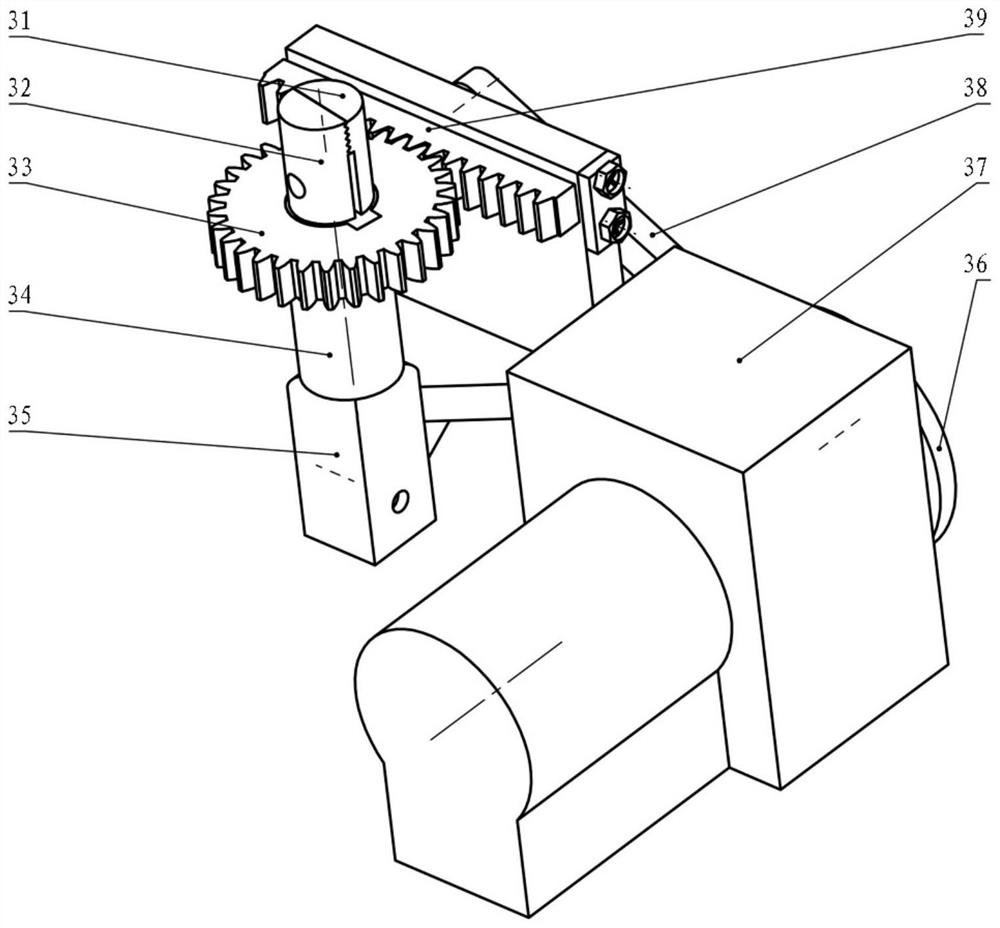

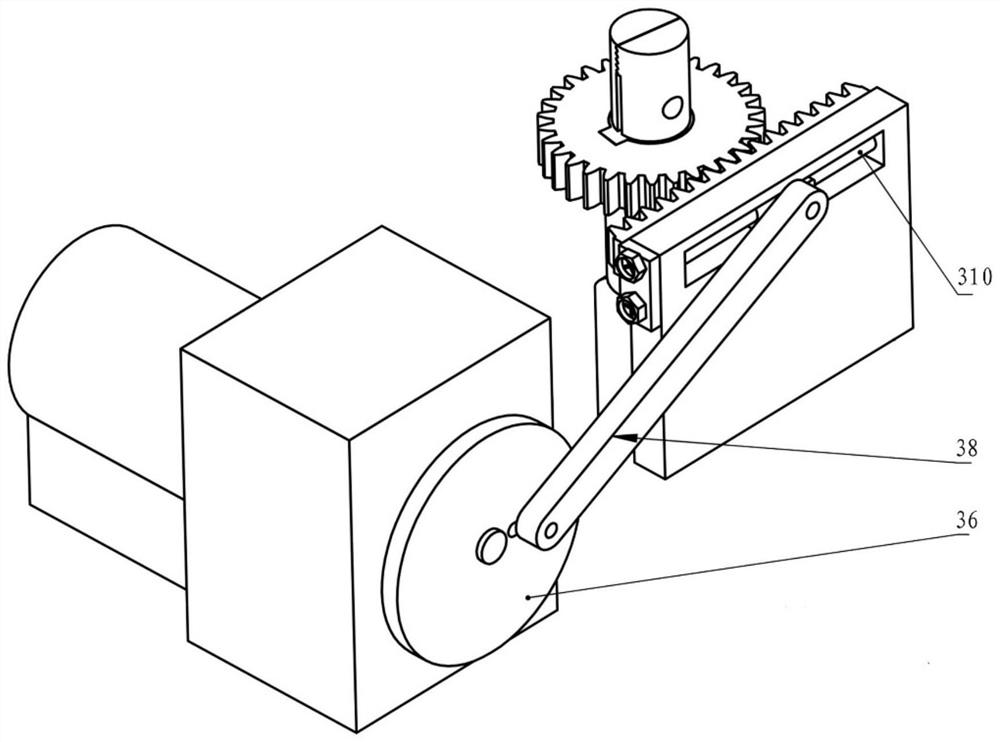

[0031] Step 1: Prepare experimental materials: prepare a servo motor 37 with a frequency range of 0.5-10 Hz, prepare a turntable 36 with a radius of 30 mm, prepare a connecting rod 38 with a length of 100 mm, prepare a reciprocating linear rack 39 with a length of 100 mm, prepare a diameter of 25mm torsion gear 33, prepare artificial anterior cruciate ligament sample A, length L1 is 80mm, diameter D1 is 6mm, has been coated with fibrinogen.

[0032] Step 2: Inspection and adjustment: place the connecting mechanism on the base of the fabric strength meter 2, fix the torsion test connection base 35 of the fabric strength meter and the base of the fabric strength meter 2 with a pin with a head, and adjust the initial position of the reciprocating linear rack 39 to The position of the center point of the chut...

Embodiment 2

[0040] This example records a fatigue simulation test method of artificial anterior cruciate ligament tensile torsion combined load, the specific test steps are as follows:

[0041] Step 1: prepare experimental materials: prepare a servo motor 37 with a frequency range of 0.5-10 Hz, prepare a turntable 36 with a radius of 40 mm, prepare a connecting rod 38 with a length of 120 mm, prepare a reciprocating linear rack 39 with a length of 120 mm, prepare a diameter of A 30mm twisted gear 33 was used to prepare an artificial anterior cruciate ligament sample A with a length L2 of 100mm and a diameter D2 of 10mm, which had been coated with fibrinogen.

[0042] Step 2: Inspection and adjustment: place the connecting mechanism on the base of the fabric strength meter 2, fix the torsion test connection base 35 of the fabric strength meter and the base of the fabric strength meter 2 with a pin with a head, and adjust the initial position of the reciprocating linear rack 39 to The posit...

Embodiment 3

[0050] This example records a fatigue simulation test method of artificial anterior cruciate ligament tensile torsion combined load, the specific test steps are as follows:

[0051] Step 1: prepare experimental materials: prepare a servo motor 37 with a frequency range of 0.5-10 Hz, prepare a turntable 36 with a radius of 50 mm, prepare a connecting rod 38 with a length of 140 mm, prepare a reciprocating linear rack 39 with a length of 120 mm, prepare a diameter of A 45 mm twisted gear 33 was prepared to prepare an artificial anterior cruciate ligament specimen A with a length L3 of 60 mm and a diameter D3 of 12 mm, which had been coated with fibrinogen.

[0052]Step 2: Inspection and adjustment: place the connecting mechanism on the base of the fabric strength meter 2, fix the torsion test connection base 35 of the fabric strength meter and the base of the fabric strength meter 2 with a pin with a head, and adjust the initial position of the reciprocating linear rack 39 to Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com