Smelting burdening method based on optimized ecological niche genetic algorithm

A genetic algorithm and niche technology, applied in the field of smelting ingredients based on optimized niche genetic algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

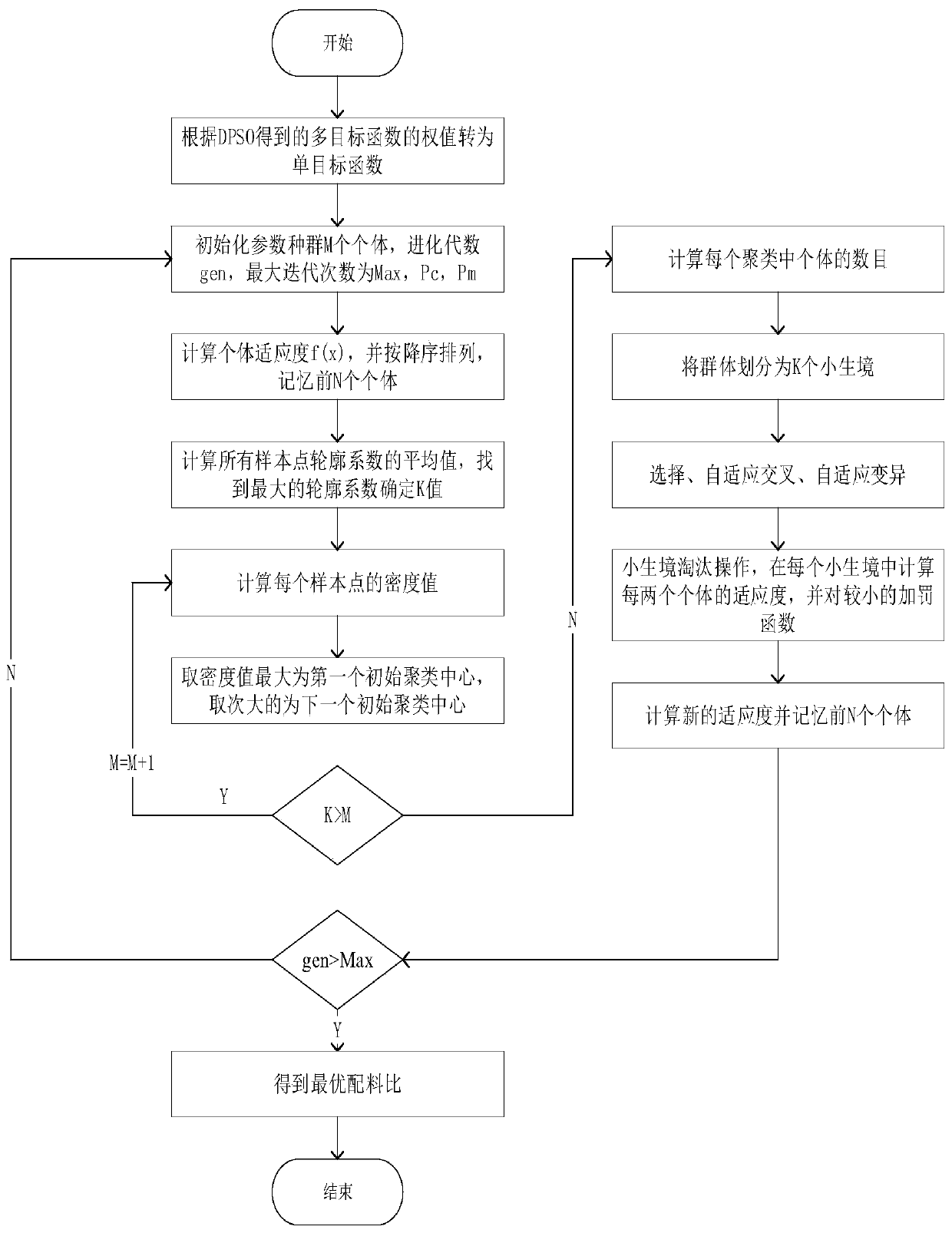

[0070] The present invention takes batching optimization as the carrier, and uses the INGA algorithm as the main algorithm framework, and its flow chart is as follows figure 1 shown, including the following steps:

[0071] S1. The multi-objective function of production cost, raw material consumption and product quality is established, and the indicators of various parameters in the production process are proposed as multi-constraint conditions, and a mathematical model for batching optimization is established.

[0072] Test verification of the present invention has built batching optimization mathematical model, and objective function is raw material cost, and formula is as follows:

[0073]

[0074] Among them, F represents the cost of raw materials used, c i Indicates the unit price of raw materials for the i-th production prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com