Efficient rolling-type pineapple harvesting machine

A rolling harvester technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of difficult operation and high cost, and achieve the effect of low operation difficulty, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

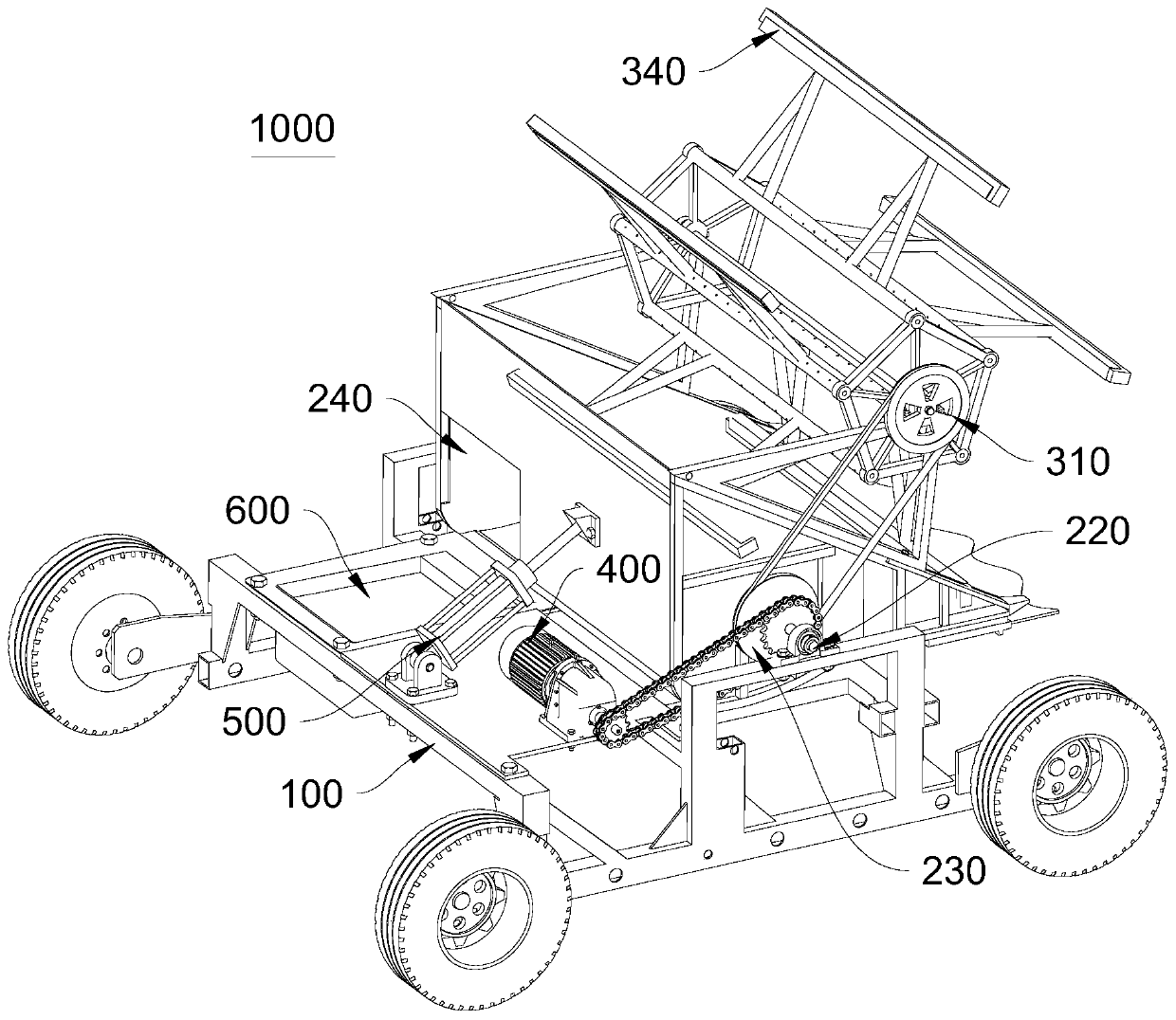

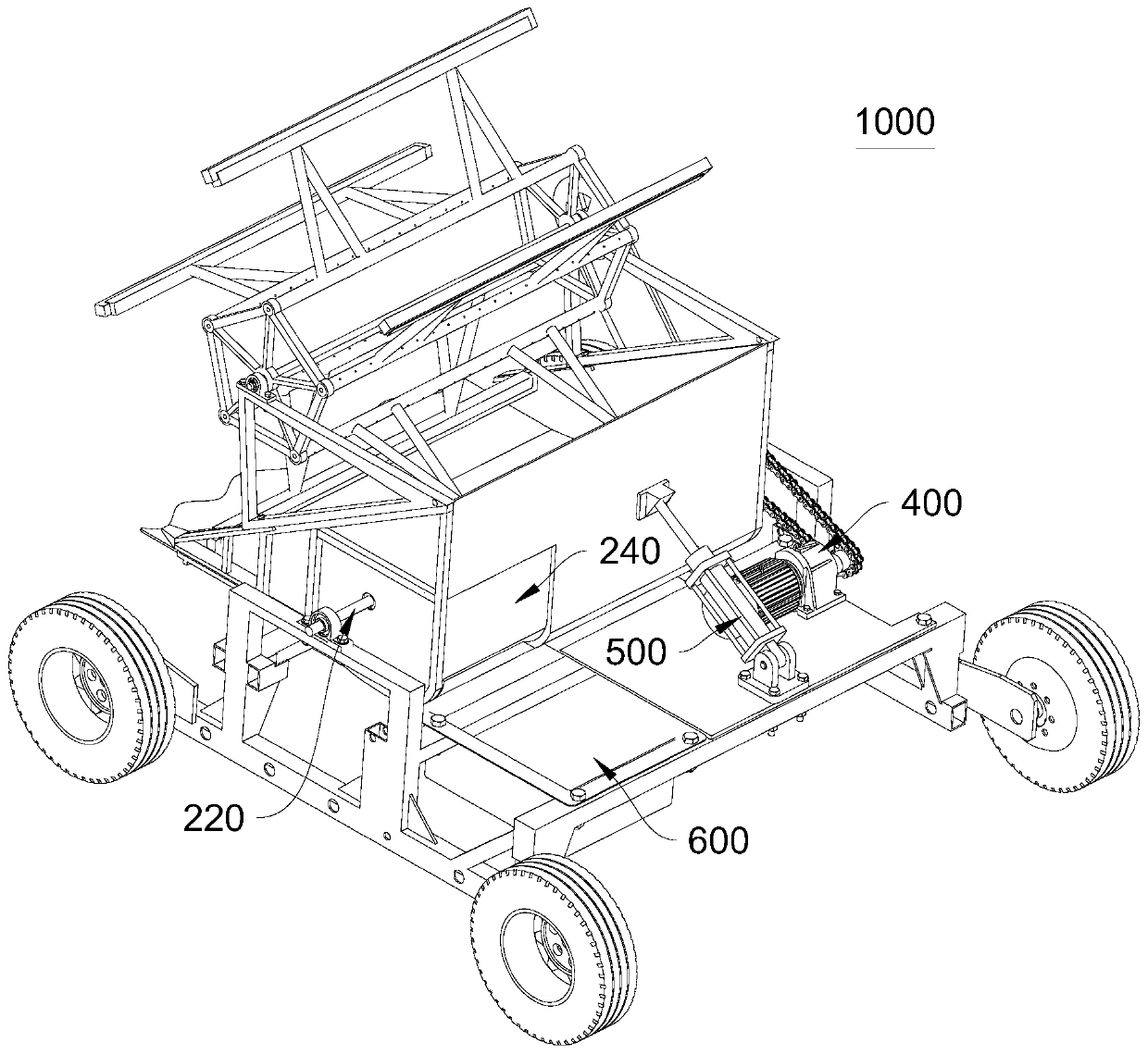

[0032] Please refer to Figure 1~3 , this embodiment provides an efficient rolling pineapple harvester 1000 , the rolling pineapple harvester 1000 includes: a base 100 , a harvesting bucket 200 and a rolling assembly 300 .

[0033] The harvesting bucket 200 is installed on the base 100, and the opening edge of the harvesting bucket 200 is provided with a stop plate 210 for abutting against the pineapple plant.

[0034] The rolling assembly 300 includes a rotating shaft 310 , an extension rod 330 and a push rod 340 . The rotating shaft 310 is rotatably mounted on the opening of the harvesting bucket 200, and the push rod 340 is arranged in parallel with the rotating shaft 310 at intervals. The extension rod 330 is connected between the rotating shaft 310 and the push rod 340, so that when the rotating shaft 310 is driven, the push rod 340 can push the fruit of the pineapple plant abutting against the edge of the stop plate 210 into the harvesting bucket 200 .

[0035] During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com