Two-stage green coffee bean baking method

A technology of green coffee beans and roasting methods, which is applied to the methods of roasting coffee, coffee, processing roasted coffee, etc. It can solve the problems that the fruity, floral, sweet and full-bodied coffee cannot be fully displayed, and achieve the best roasting operation. Simple and convenient, enhance the flavor and taste, and the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

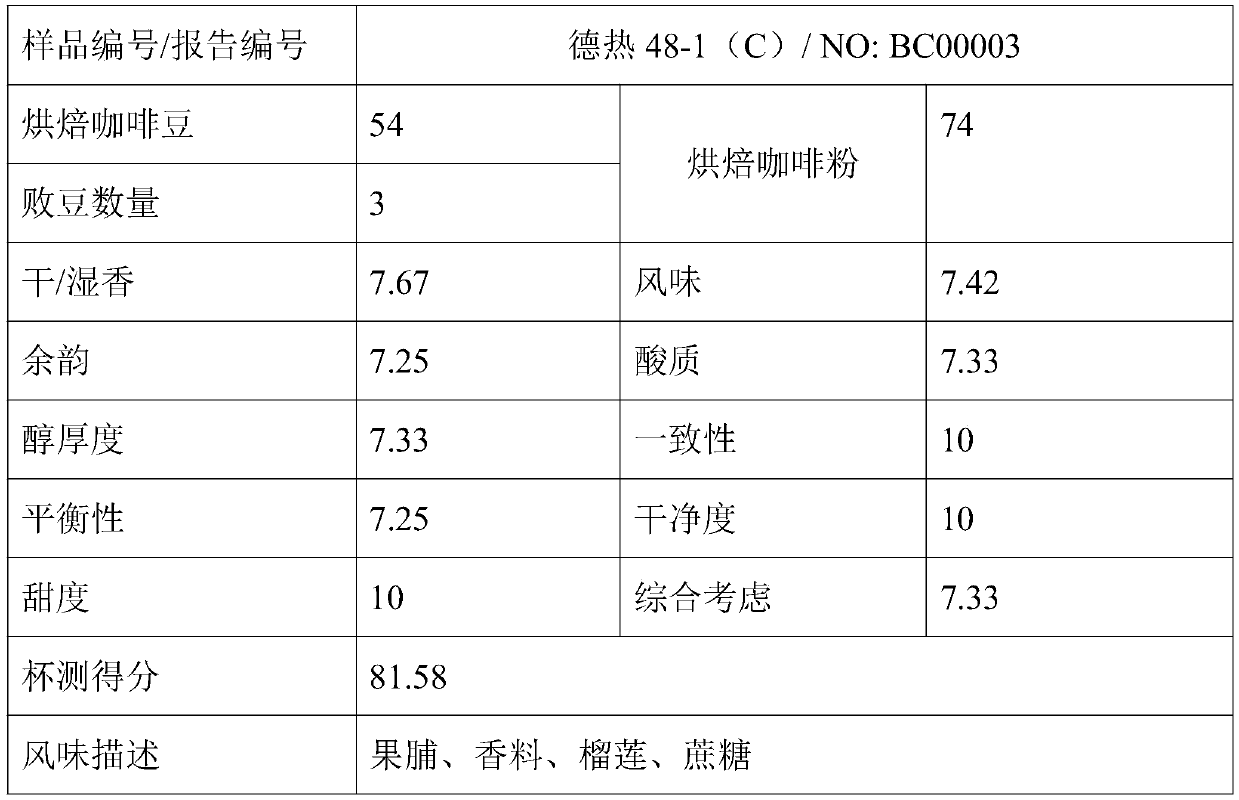

[0036] Embodiment 1 (corresponding to C in the test report)

[0037] A two-stage method for roasting green coffee beans, comprising the following steps:

[0038] S 11 The first stage of roasting: the green coffee beans are roasted in the first stage to obtain roasted beans. The temperature of the first stage of roasting is 170°C, and the time of the first stage of roasting is 8.

[0039] The green coffee beans are the green coffee beans obtained by blast-drying the picked coffee berries.

[0040] S 12 Cooling: Take out the roasted beans of S1 and let it stand for 10 seconds.

[0041] S 13 The second stage of roasting: the cooled roasted beans are subjected to the second stage of roasting to obtain roasted beans, the temperature of the second stage of roasting is 210° C., and the time of the second stage of roasting is 6 minutes.

[0042] S 14 Cooling and waking up the beans: remove the silver skin from the roasted beans of S3, cool to room temperature, and let stand for 3 da...

Embodiment 2

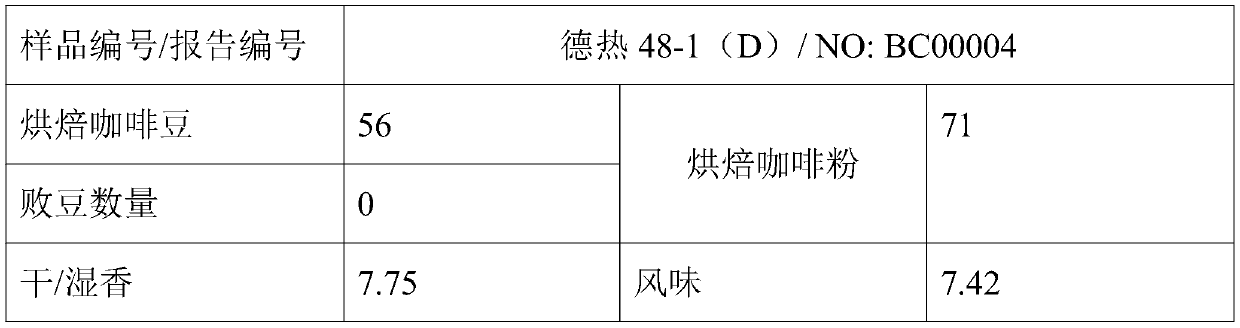

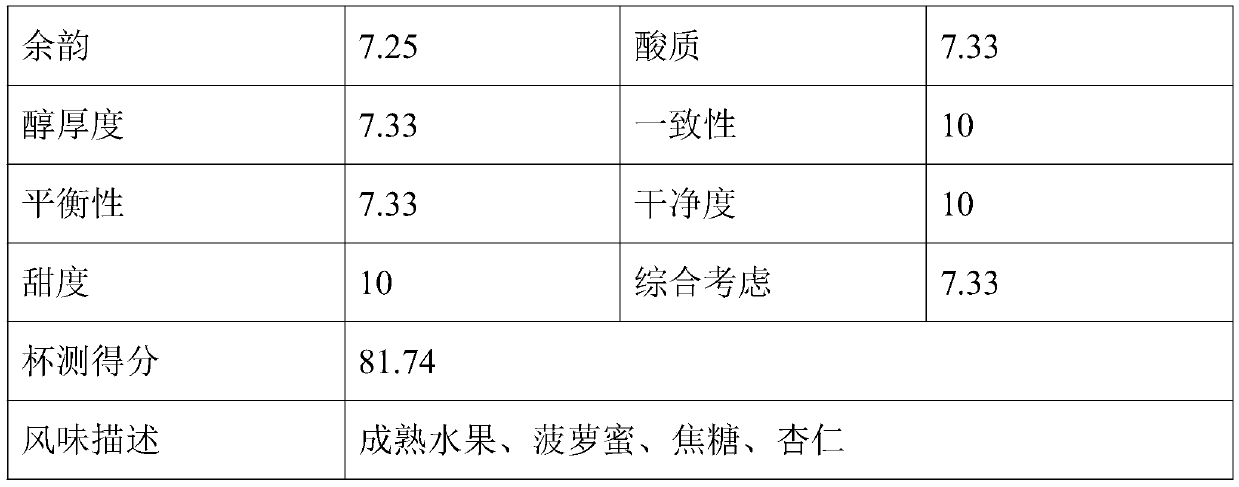

[0044] Embodiment 2 (corresponding to D in the test report)

[0045] A two-stage method for roasting green coffee beans, comprising the following steps:

[0046] S 21 The first stage of roasting: the green coffee beans are roasted for the first stage to obtain roasted beans, the temperature of the first stage of roasting is 180°C, and the time of the first stage of roasting is 10 minutes.

[0047] The green coffee beans are the green coffee beans obtained by blast-drying the picked coffee berries.

[0048] S22 Cooling: Take out the roasted beans of S1 and let it stand for 15 seconds.

[0049] S 23 The second stage of roasting: the cooled roasted beans are subjected to the second stage of roasting to obtain roasted beans, the temperature of the second stage of roasting is 220° C., and the time of the second stage of roasting is 8 minutes.

[0050] S 24 Cooling and waking up the beans: remove the silver skin from the roasted beans of S3, cool to room temperature, and let stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com