Patents

Literature

30results about How to "Keep fruity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for performing microwave drying on grosvener siraitia and grosvener siraitia dried by same

ActiveCN102125248ARegular shapeFruit shape is beautifulDigestive systemRespiratory disorderNavelMogroside V

The invention discloses a method for performing microwave drying on grosvener siraitia and the grosvener siraitia dried by the same. The method comprises the following steps of: washing the grosvener siraitia completely and performing green-removing; punching a small hole on the top of the grosvener siraitia and the corresponding fruit navel at the bottom of the grosvener siraitia respectively; placing the punched grosvener siraitia into microwave drying equipment to dry for 8 to 10 minutes under the conditions of 2,400 to 2,500 MHz or 915 MHz and the temperature of between 50 and 60 DEG C; taking out the grosvener siraitia; placing the grosvener siraitia into the microwave drying equipment to dry for 8 to 10 minutes under the same conditions; taking out; cooling the grosvener siraitia at the temperature of between 0 and 4 DEG C for 3 to 5 minutes; and repeating the drying and cooling processes for 5 to 6 times to obtain grosvener siraitia. Compared with the prior art, the method has the advantages of simple and easily controlled process, short drying time and low energy consumption. The obtained dried grosvener siraitia has a complete and attractive fruit shape, green color, good mouthfeel and high retention rate of mogrosides V.

Owner:GUILIN NATURAL INGREDIENTS CORP

Drying method of momordica grosvenori and momordica grosvenori obtained by using same

ActiveCN102125249ARegular shapeFruit shape is beautifulDigestive systemRespiratory disorderGlycosideMomordica

The invention discloses a drying method of momordica grosvenori and the momordica grosvenori obtained by using the same. The drying method comprises the steps of: cleaning the fresh momordica grosvenori, deactivating enzyme, putting the enzyme-deactivated momordica grosvenori into a freeze dryer, reducing the temperature from -40 DEG C to -60 DEG C, controlling a temperature reducing process within 1-3h, rising the temperature to -25 DEG C to -15 DEG C by the temperature rising speed rate of 1.2-7.5 DEG C / h, rising the temperature to 20-25 DEG C by the temperature rising speed rate of 3.5-10 DEG C / h, and keeping the temperature for 4-8 hours. Compared with the prior art, the enzyme of the fresh momordica grosvenori is deactivated to restrain the activity in the enzyme, and the momordica grosvenori is dried in a freezing way under a special temperature condition to obtain the dried momordica grosvenori which is integrated in shape and beautiful, and has the same color and luster as the fresh momordica grosvenori; the momordica grosvenori is good in mouthfeel, the special fruity of the fresh momordica grosvenori is kept, and the conservation rate of the momordica glycosides V in the dried momordica grosvenori is high; and the invention is simple and controllable in technology, low in energy consumption, and less in the loss of nutrition constituents in the fresh momordica grosvenori.

Owner:GUILIN NATURAL INGREDIENTS CORP

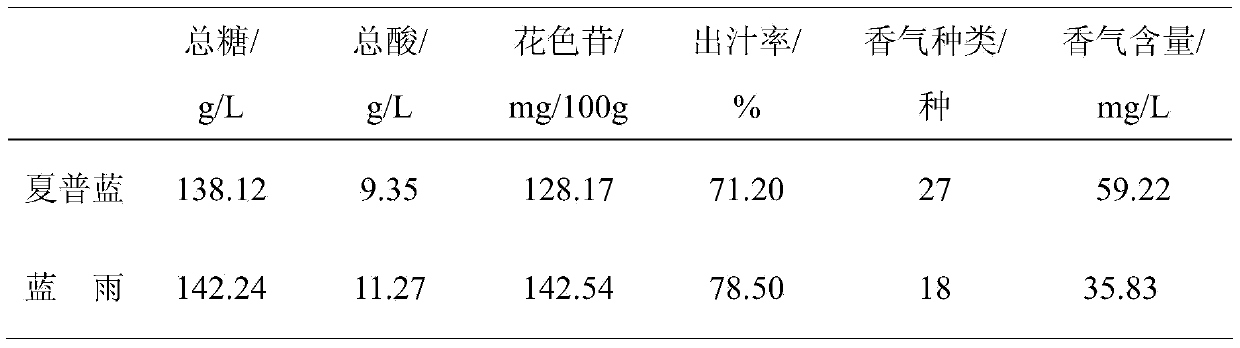

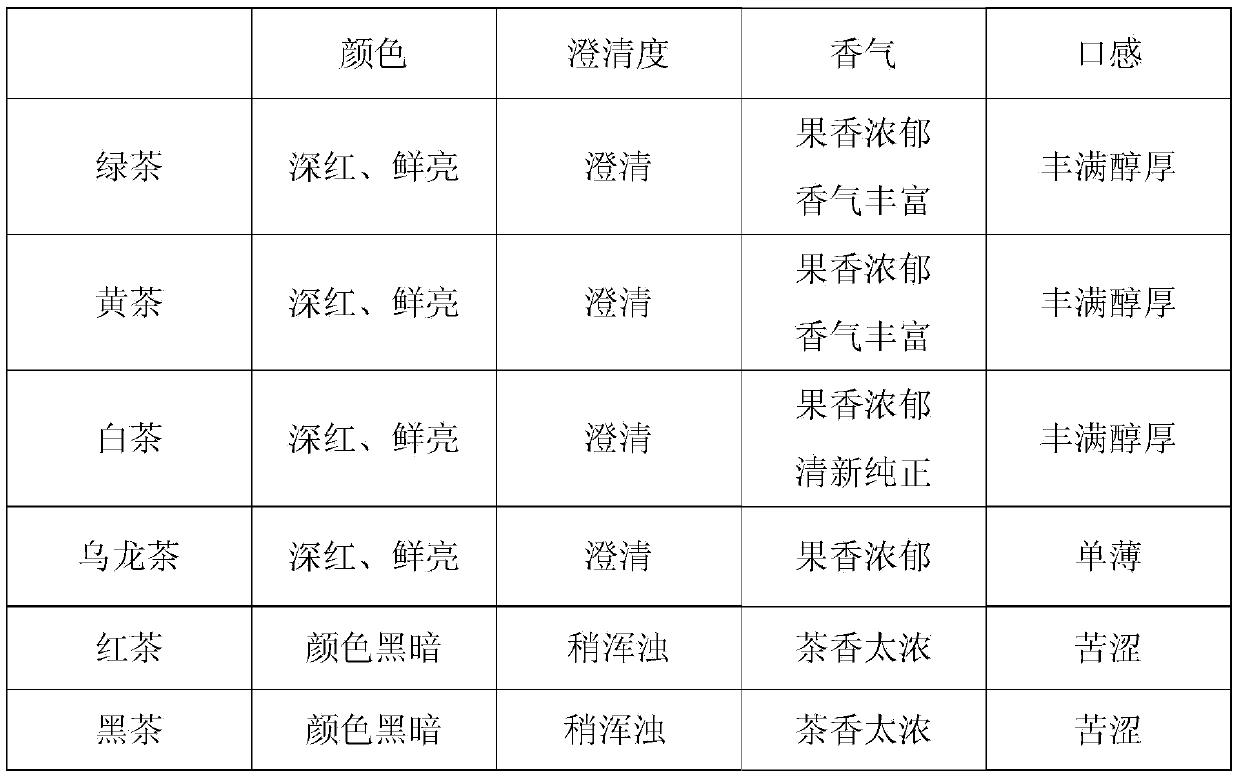

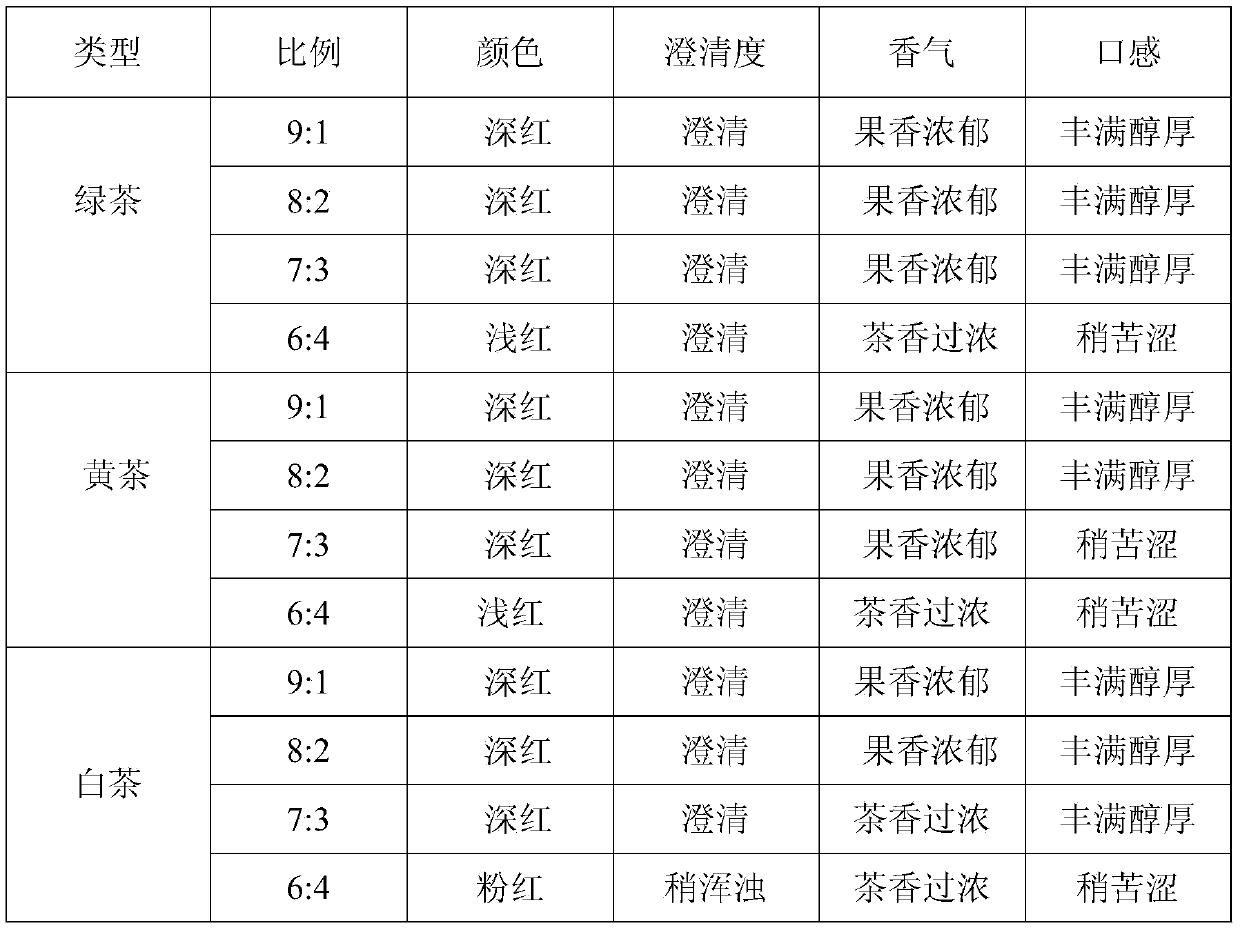

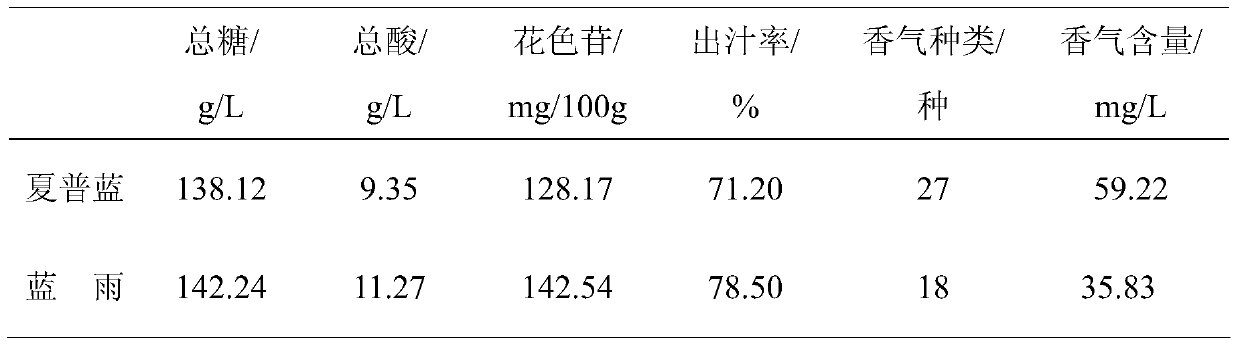

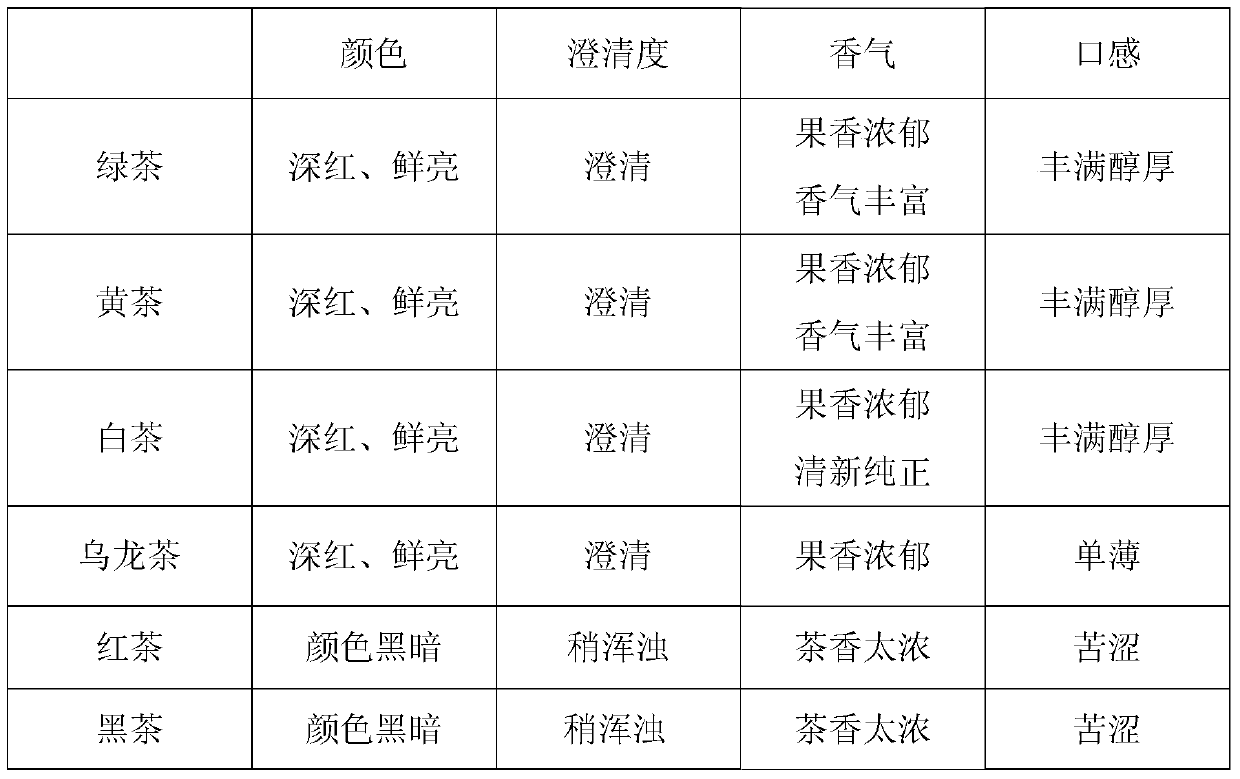

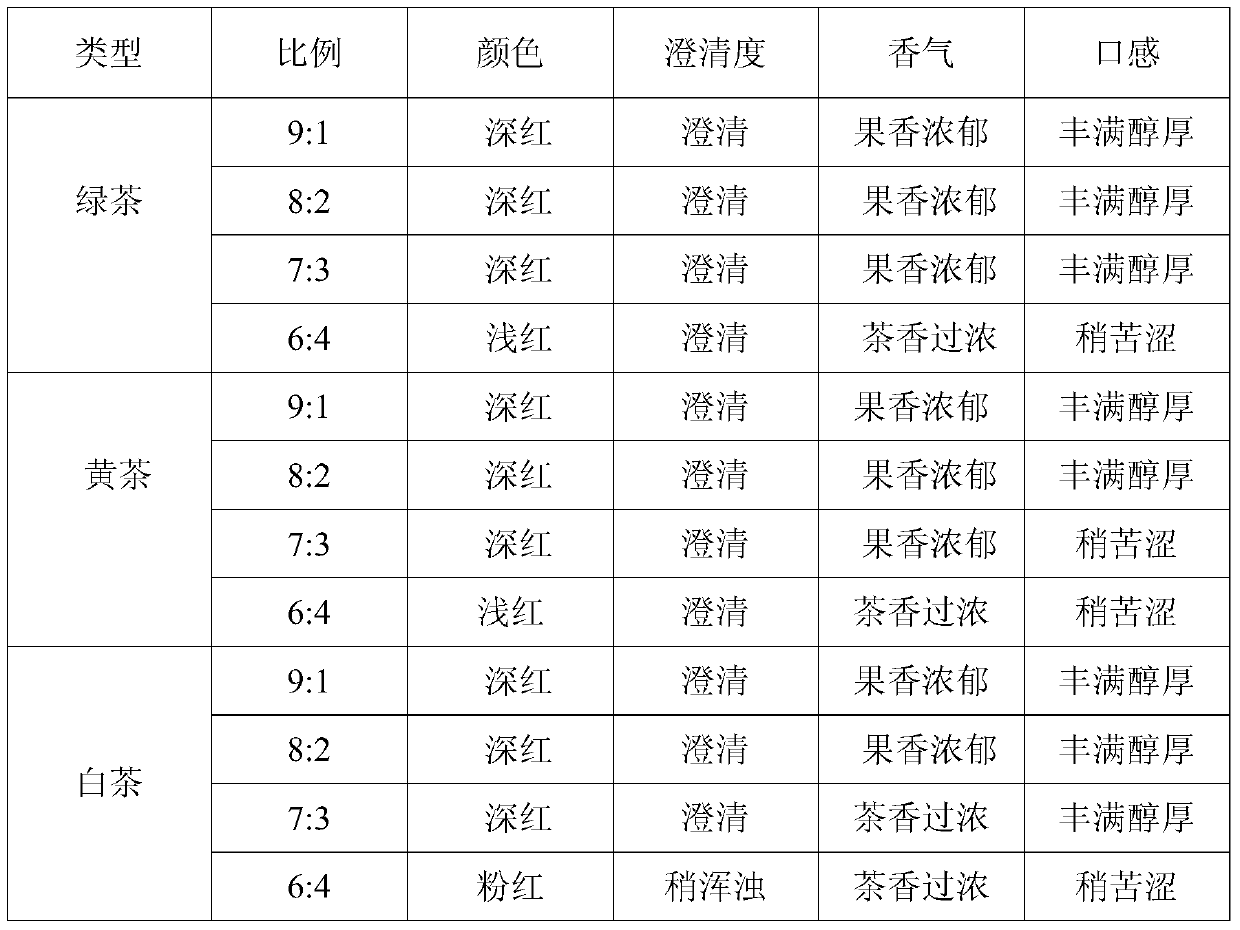

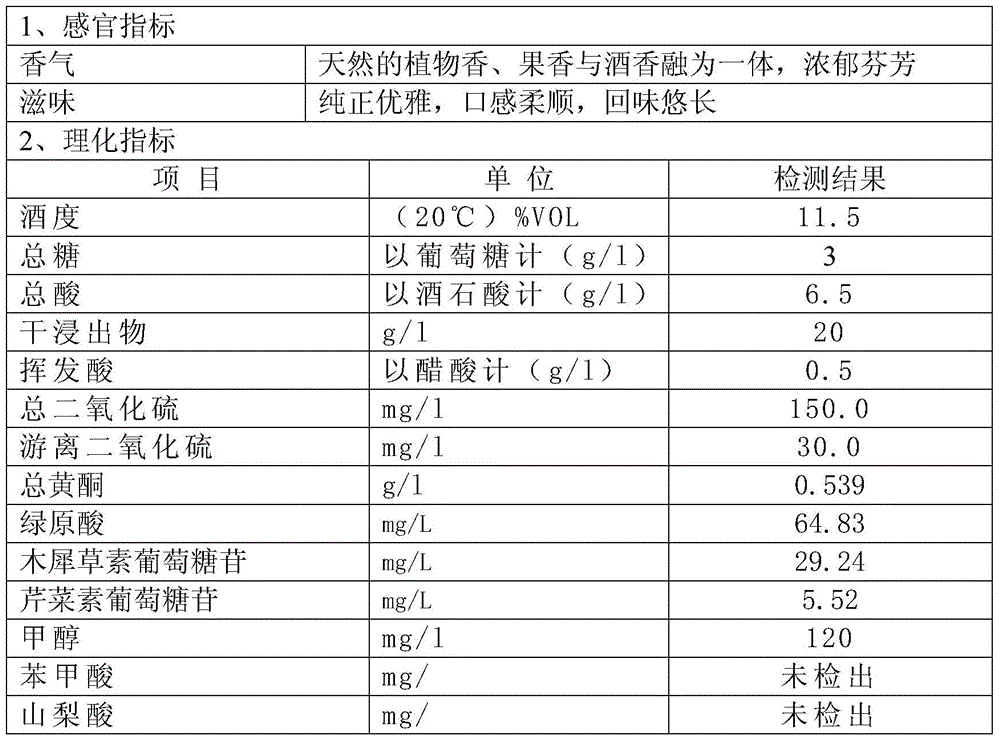

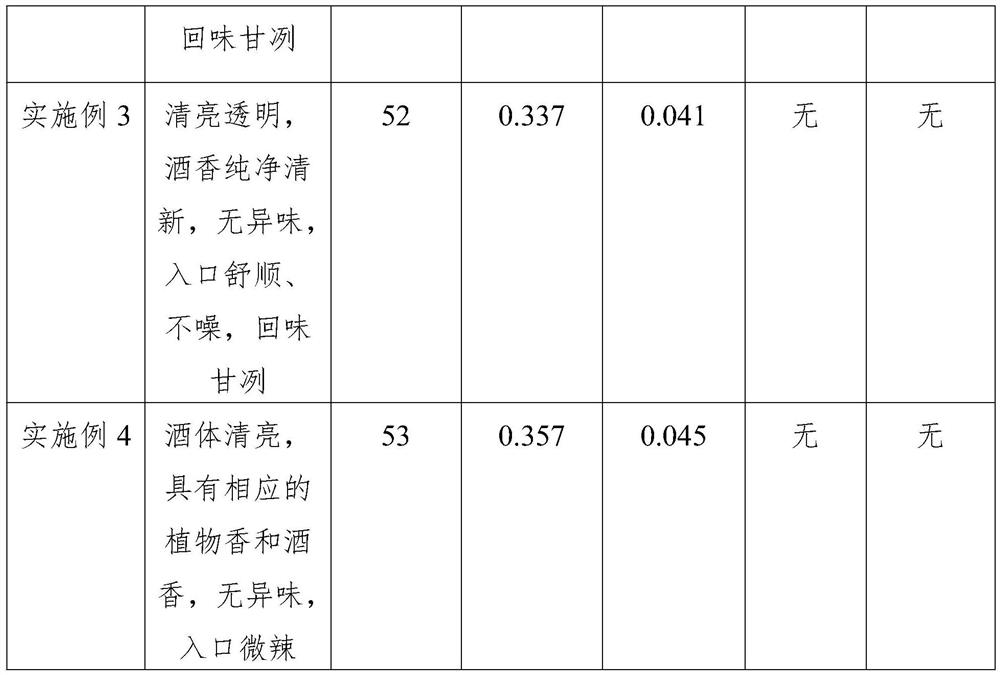

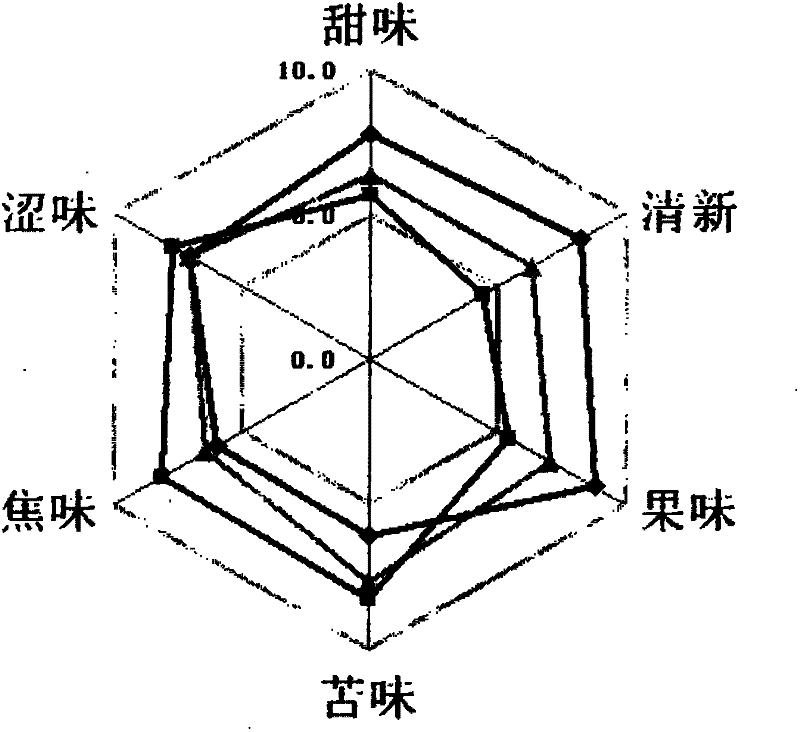

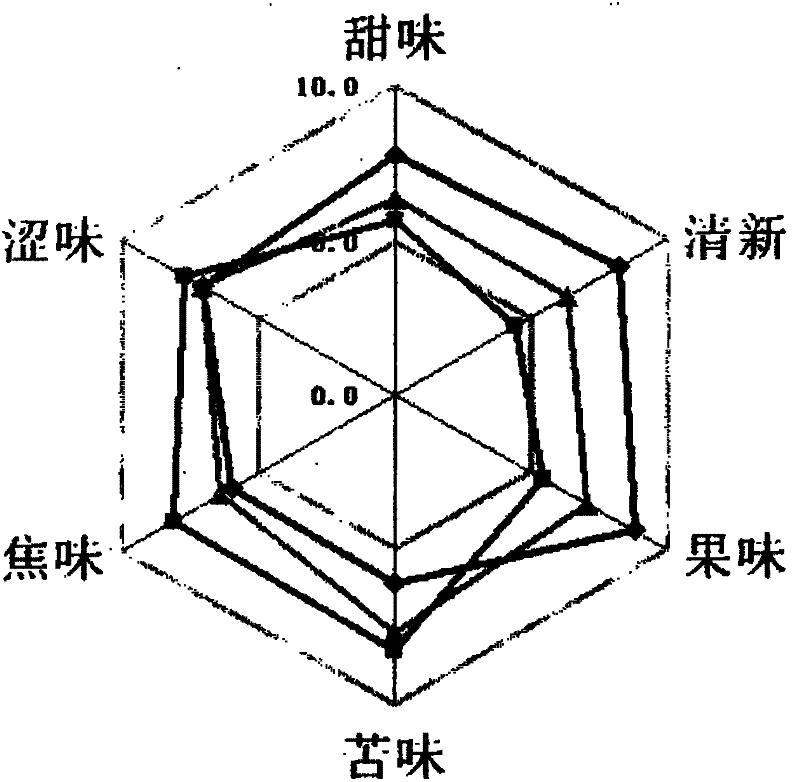

Brewing method of lower-alcohol blueberry health-care wine

ActiveCN105368631ADeep colorStrong aromaAlcoholic beverage preparationMicroorganism based processesFruit wineStable state

The invention discloses a brewing method of lower-alcohol blueberry health-care wine. The method comprises the steps of blueberry selection and processing, tea preprocessing, raw material blending, ethanol fermentation, ageing, clarification stabilizing processing and the like. The method uses an optimized blue rain variety of blueberries as raw materials, and meanwhile tea leaching liquid, prebiotics and soluble dietary fibers are added; the lower-alcohol blueberry wine is obtained through raw pulp steeping, high-temperature enzymolysis, high-temperature start, mixed-bacteria synergy and low-temperature long-time fermentation; low-temperature ageing is assisted by microwaves to accelerate wine body mature, and the quality of the fruit wine is improved; a wine body is higher in clarity and is kept in a stable state for a long period of time through clarification stabilizing processing; the taste of the wine is improved and meanwhile a health-care function is increased for the wine by adding a functional sweetener. By the adoption of the process, the high-quality lower-alcohol blueberry wine having good color, fragrance and taste and integrating nutrition and health care can be obtained.

Owner:HUANGSHAN BLUEBERRY ECOLOGICAL PARK CO LTD

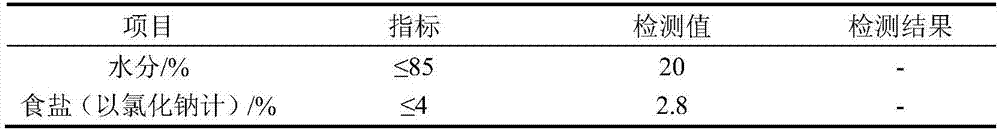

Preparation method of accompaniment pomelo peel and red jujube health-care dish

InactiveCN107568653APrevent fat oxidationPreserve nutritional value and health functionFood scienceZiziphus jujubaFlavor

The invention relates to a preparation method of an accompaniment pomelo peel and red jujube health-care dish. The preparation method comprises the following steps: raw material pretreatment: treatingpeanuts and pomelo peel; performing efficient pickling under pulse transformation; then, performing anaerobic fermentation, and adding lactic acid bacteria and a fermentation aid; and finally, performing cooling, post-curing and drying to form the product. The pomelo peel is adopted instead of condiments so as to prevent oxidation among flavor substances. Aroma substances such as limonene, myrcene, beta-pinene, alpha-Panasinsen and germacrene D in the pomelo peel can cover up unpleasant flavor substances and inhibit combination reaction among various smells, so that the dish can keep a fruitysmell for a long term.

Owner:NINGXIA ZHONGXI JUJUBE IND LTD LTD

Movable suspension multifunction roast duck oven using coke

A movable suspending-type multifunctional coke over for roasting duck is composed of oven, coke stove, rotary hanger, oil collector, temp display, observing lamp, blower and moving unit. Its advantages are small size of oven, light weight, and good thermal insulation property, using coke as fuel, no smoke and harmful gas generation, no pollution, and high quality of roast duck.

Owner:张黑喜

Preparation method for low alcohol litchi fruit wine beverage

InactiveCN103710201AMask sour and astringent tasteKeep fruityAlcoholic beverage preparationLitchi fruitYeast

The invention discloses a preparation method for low alcohol litchi fruit wine beverage, and belongs to the food processing field. The preparation method comprises the steps of pulping fresh litchi fruit into pulp; adding a distiller's yeast; fermenting at a low temperature; centrifuging and filtering; seasoning; sterilizing and canning to obtain the low alcohol litchi fruit wine beverage. The low alcohol litchi fruit wine beverage retains fruit fragrance of the litchi and mellow of the wine, has sweet and sour taste popular by publics, and is a fruit wine beverage suitable to people of all ages.

Owner:陈英

Method for making raspberry fruit wine by using staged fermentation

The invention discloses a method for making raspberry fruit wine by using a staged fermentation process. Fermentation characteristics of raspberry are fully taken into account in the making process; firstly the raspberry is preliminarily decomposed under the action of pectinase so as to provide a good environment for mixture system fermentation; then natural fermentation is performed by utilizingrich yeast in the raspberry fruits so as to reduce the acidity of mash and to fully exert unique flavor of raspberry fruit wine; and then residual sugar fermentation is performed through secondary fermentation utilizing yeast and a yeast nutrient to obtain the raspberry fruit wine. The method greatly preserves the fruity aroma of fresh fruits, and the fruit wine has rich and lingering fruit aroma,fully exerts characteristics of the fresh fruits, and perfectly preserves the nutrition of the fresh fruits. The quality of the fruit wine is improved and development of the fruit wine market is further promoted.

Owner:NORTHWEST NORMAL UNIVERSITY

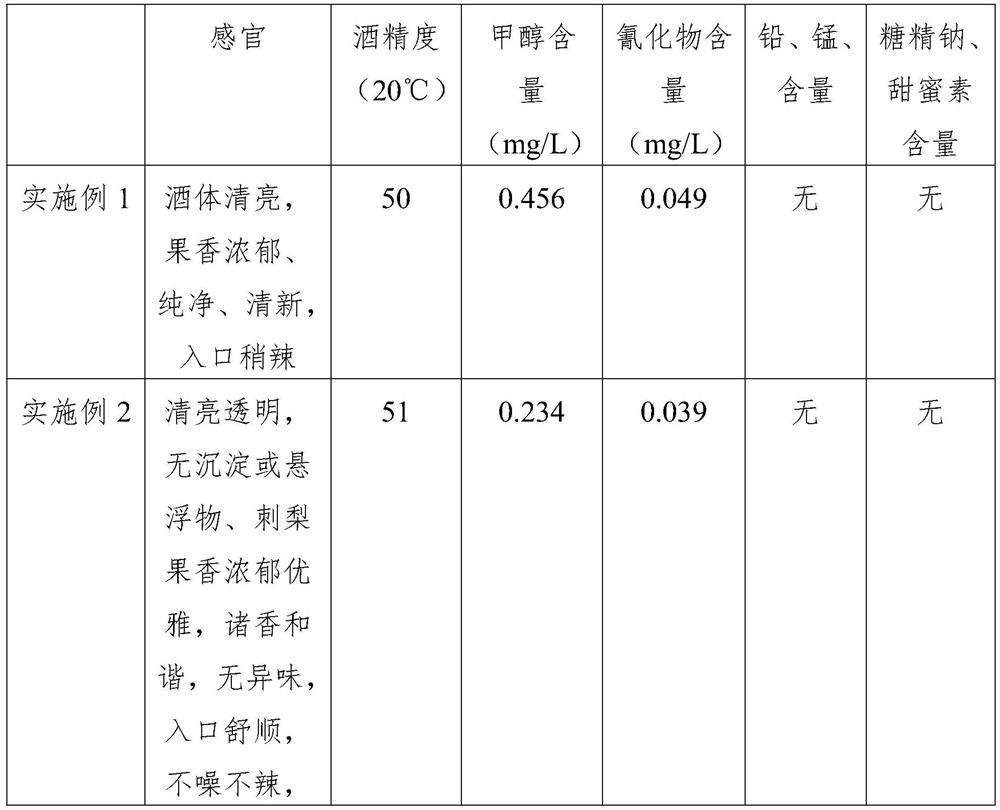

Making method of red date and rosa roxbunghii wine

The invention provides a making method of a red date and rosa roxbunghii wine, and relates to the technical field of fruit wine making. The red date and rosa roxbunghii wine is made through the production technology of sifting and cleaning, juice taking, low-temperature enzymolysis for impregnation clarification, component adjustment, low-temperature fermentation; colloid discharging for clarification, detection of cold and hot stability, and sterilization, filtration and packaging. Fresh fruits of rosa roxbunghii and dry fruits of red dates are prepared into clarified fermentation juice according to the weight ratio of 5:1 through pectinase with low yield of methyl alcohol, low-temperature fermentation is conducted to reserve the fruit aroma to the greatest extent, and mixing colloid discharging clarification treatment is conducted to obtain the largest clarification degree and reduce the browning risk of the finished product. The made red date and rosa roxbunghii wine is rich in various nutritive elements, has the fruit aroma and sweet aroma of the rosa roxbunghii and red dates, and is free of bitter taste; besides, the liquor body is light brown in color and luster, clarified and transparent, and high in stability.

Owner:MOUTAI INST

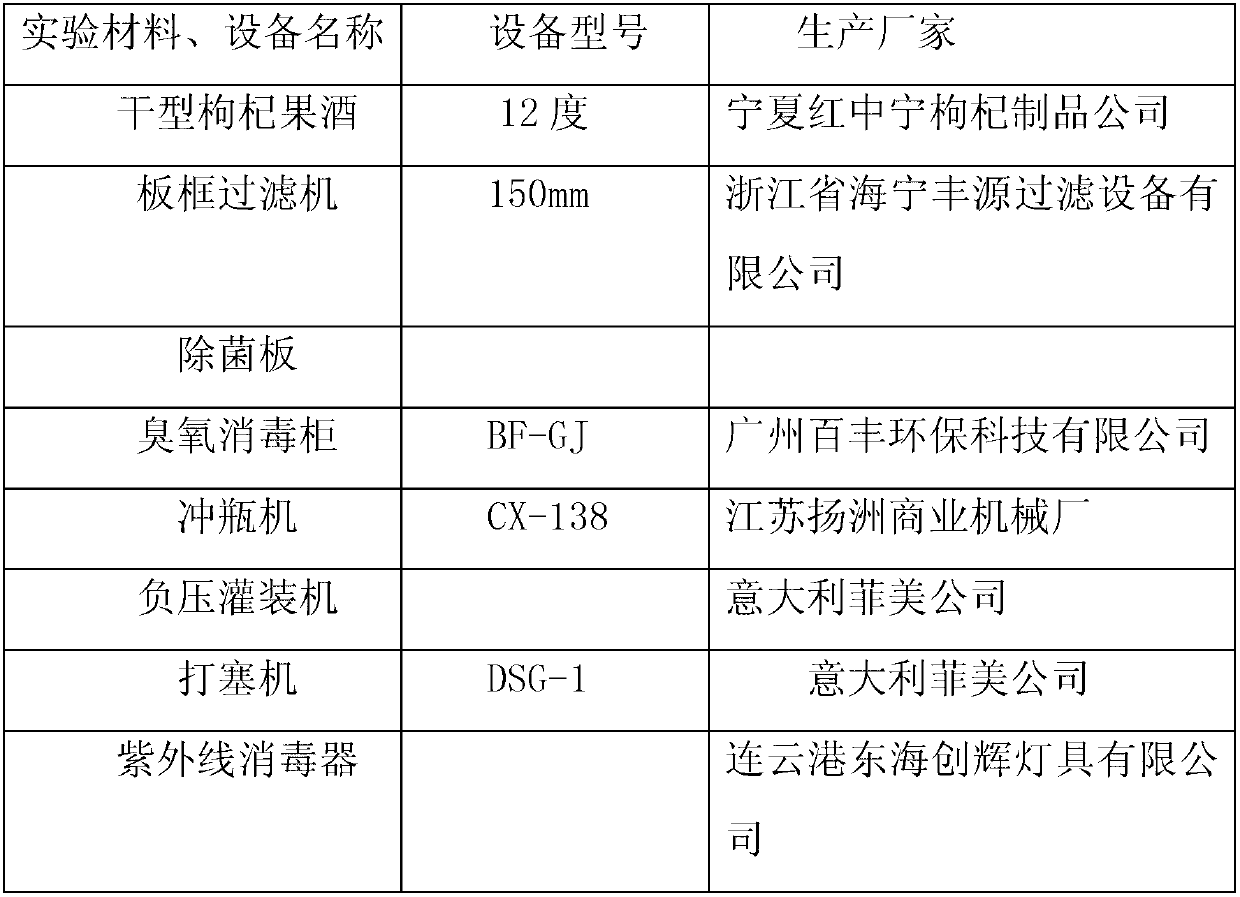

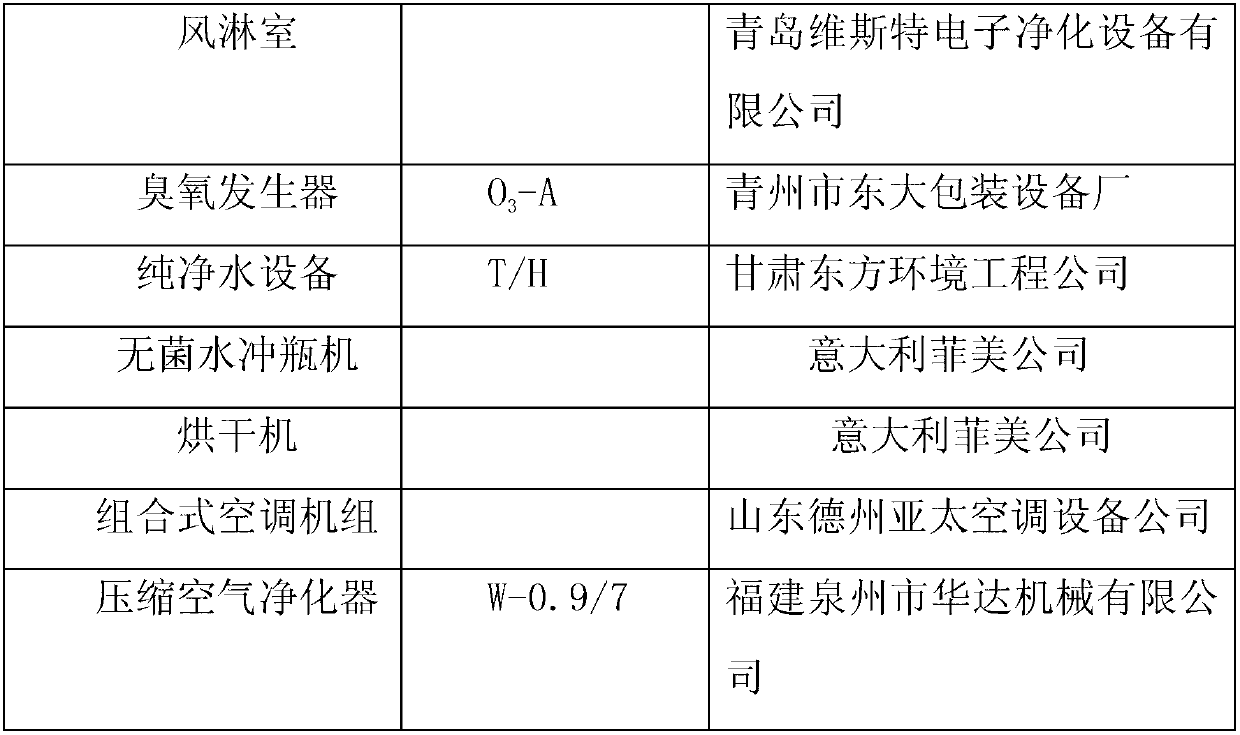

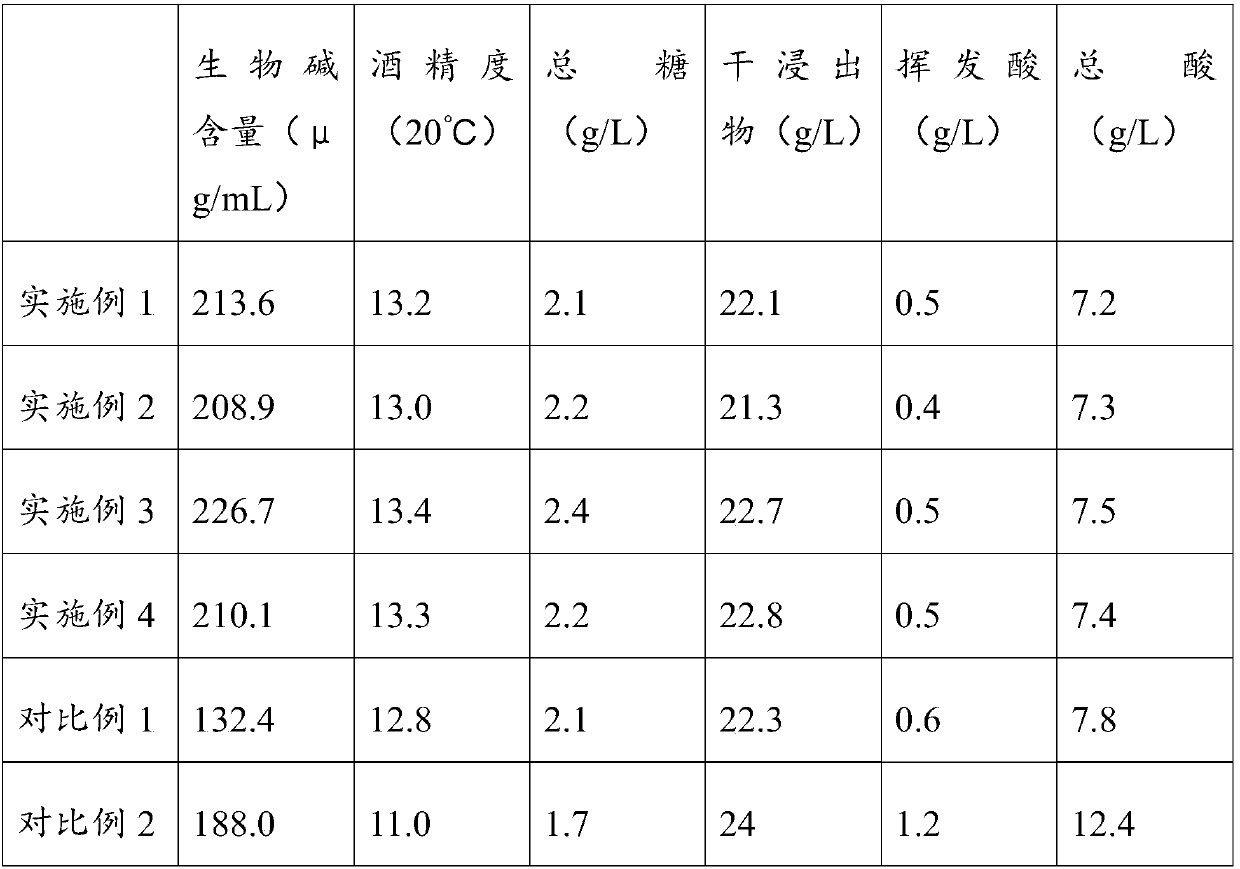

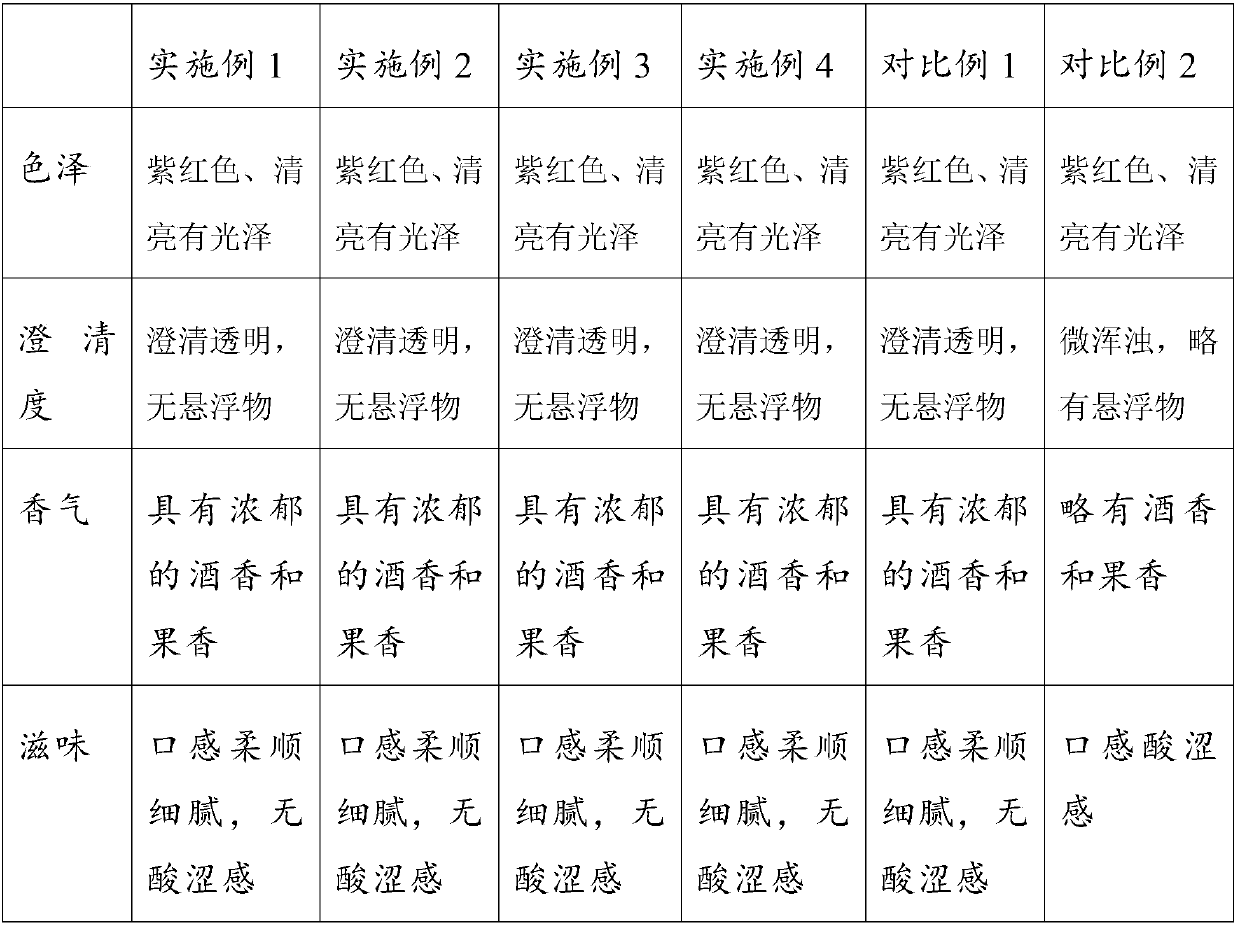

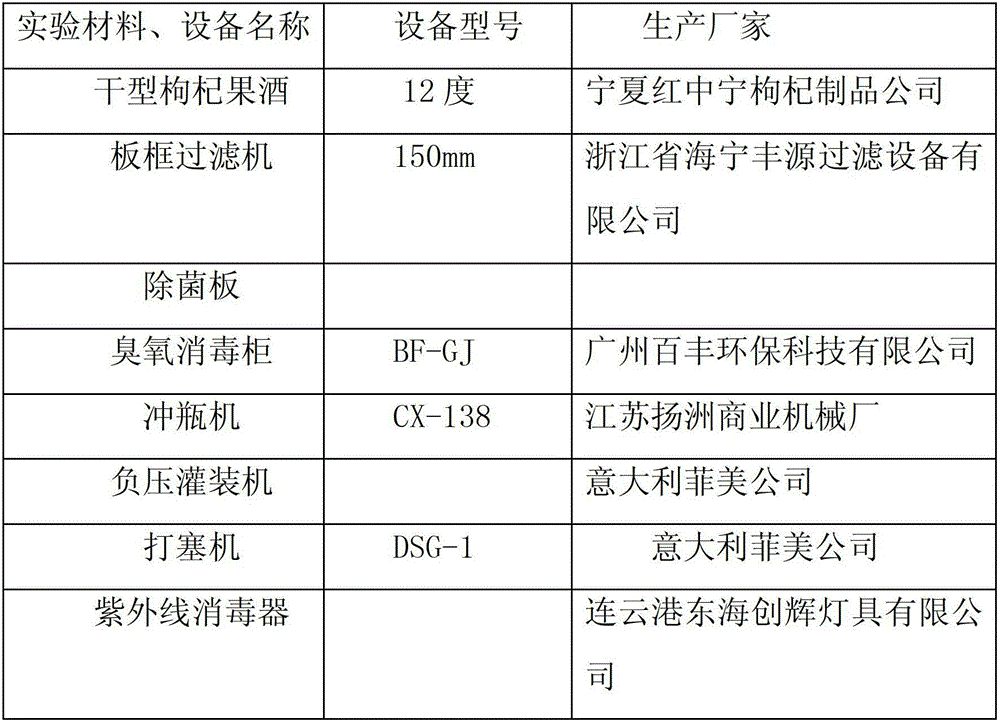

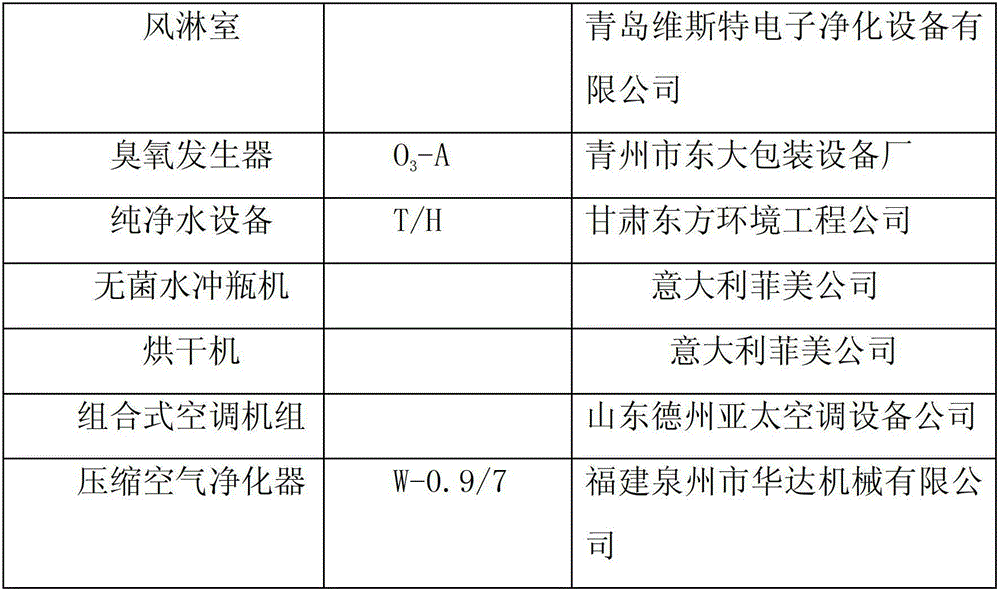

Sterile cold-filling method of dry type goji berry fruit wine

The invention relates to a sterile cold-filling method of dry type goji berry fruit wine. The method is characterized by comprising the following steps: disinfecting and sterilizing all the devices and apparatuses contacted by dry type goji berry fruit wine in the process of filling firstly, then degerming and filtering the dry type goji berry fruit wine and finally completing processes of filling, corking and sealing of the wine liquid in a sterile and clean space, and thus completing sterile cold-filling. The invention provides a sterile cold-filling method of dry type goji berry fruit wine; the quality of the product is ensured by the sterile cold-filling; the wine is filled under a normal-temperature aseptic condition in cold-filling, so that the intrinsic colour and luster, fruity flavor, taste and nutritional ingredient are maintained at a maximum extent; the requirement on the bottle in the cold filling is low, so that the bottle body is prevented from bearing hot and cold shock; and consumption a great amount of steam is not needed in the cold filling, and only the normal-temperature filling is needed.

Owner:宁夏红枸杞产业有限公司

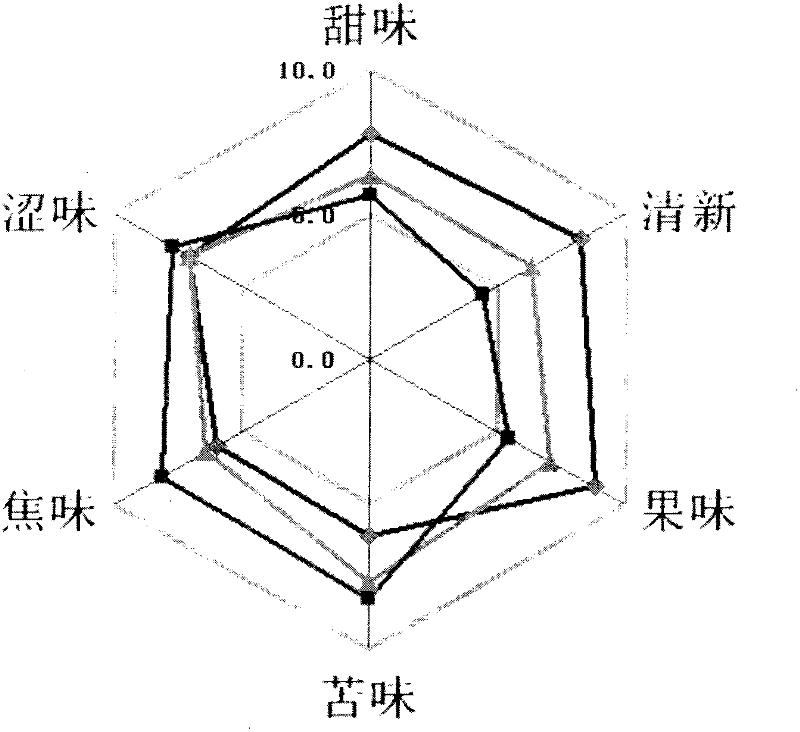

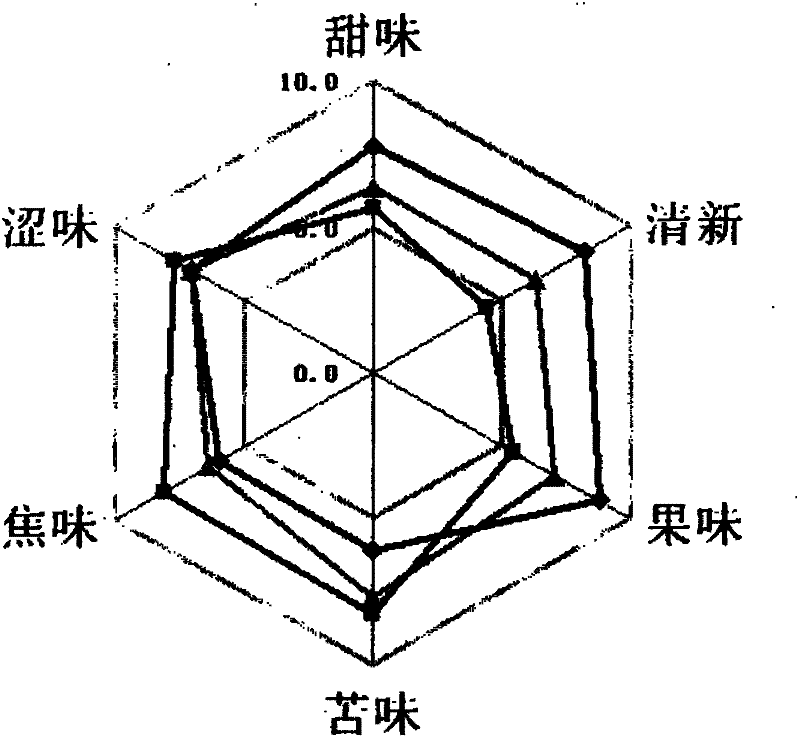

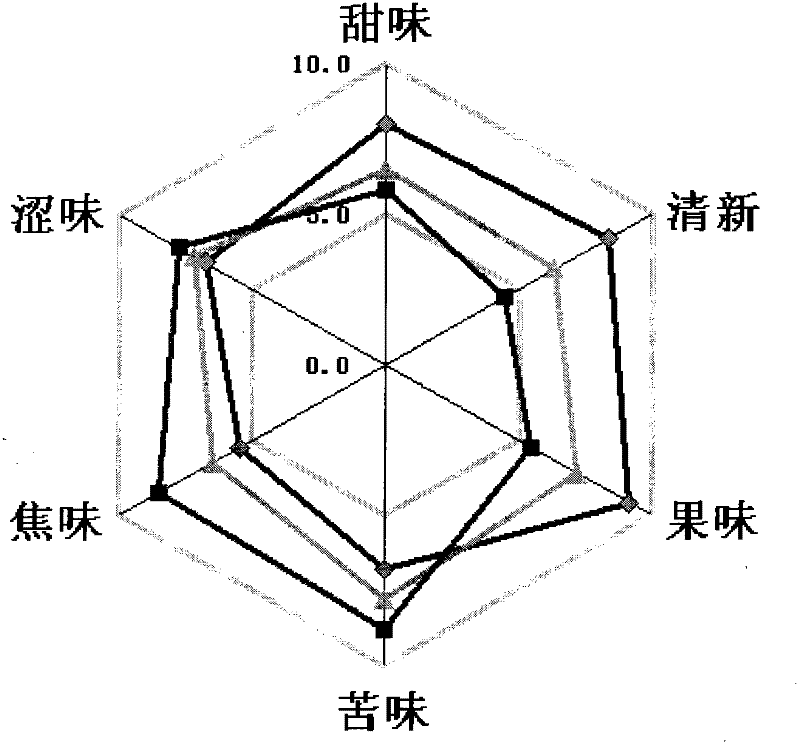

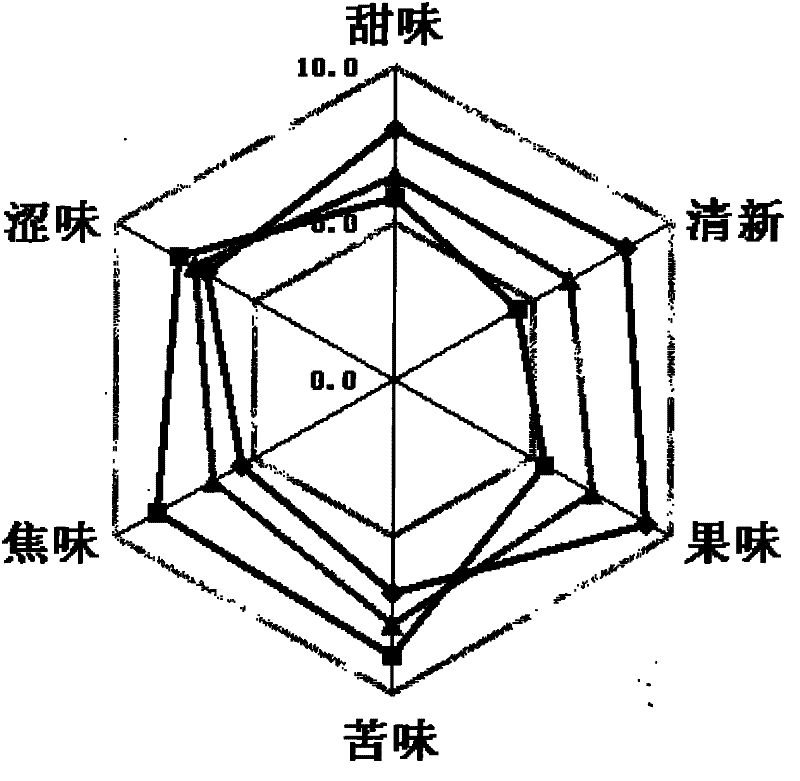

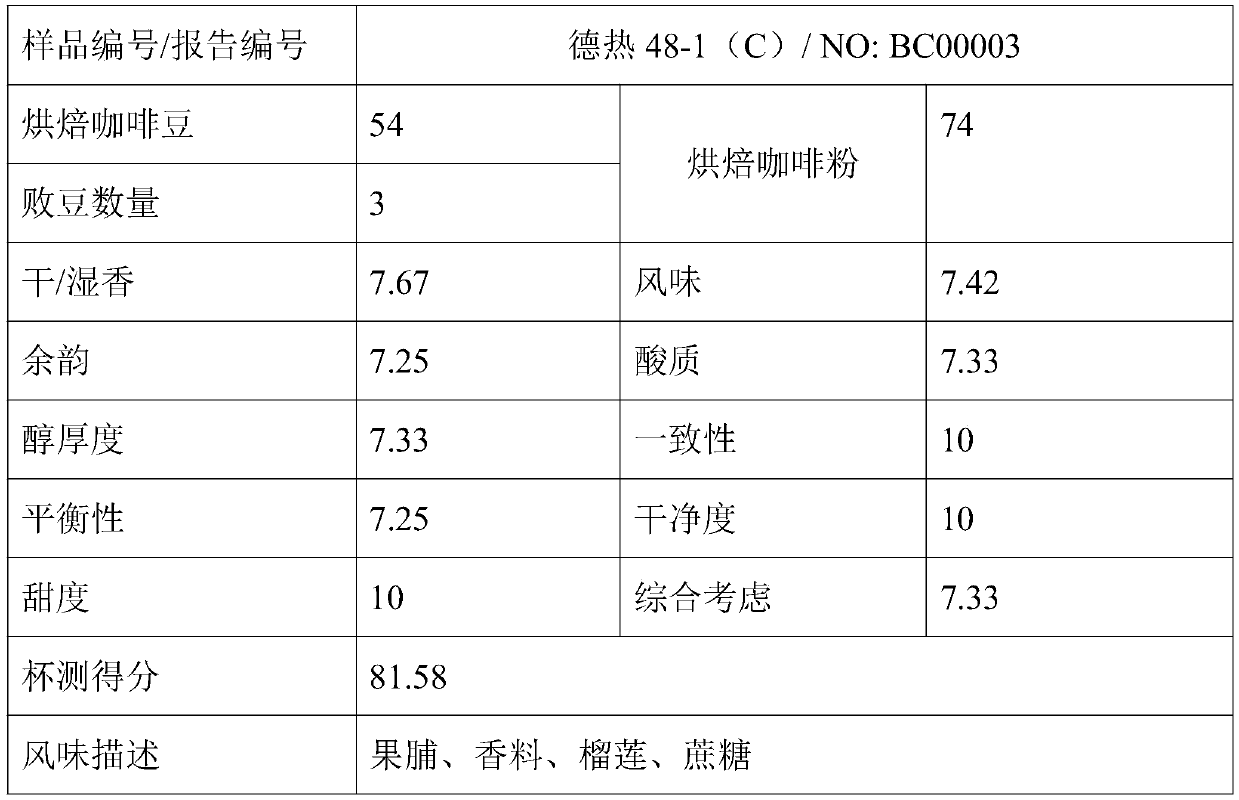

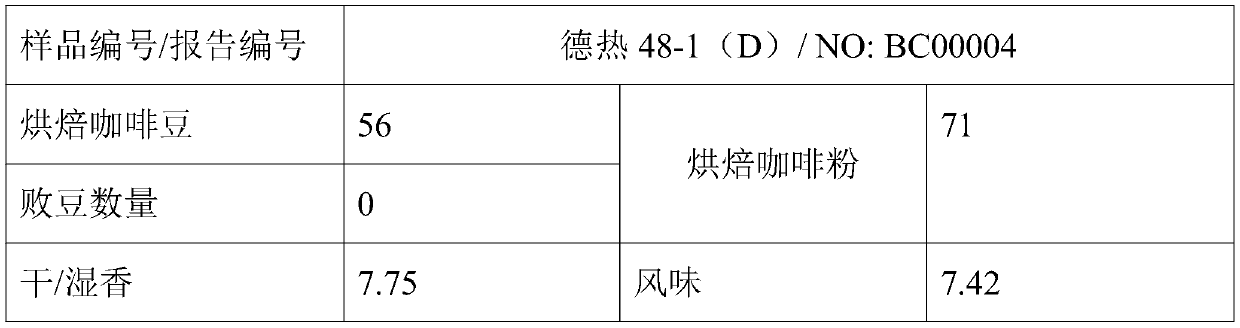

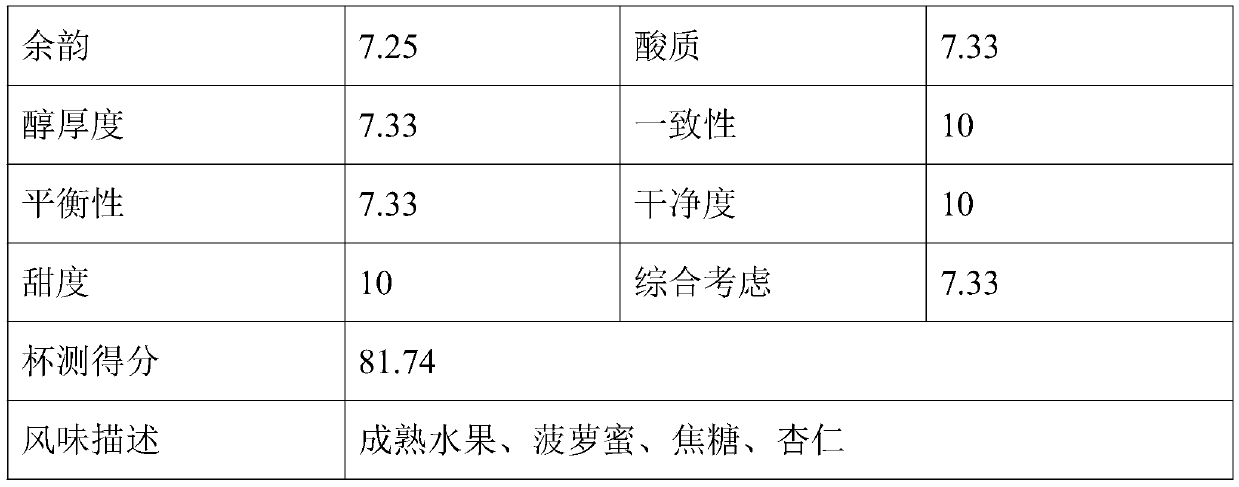

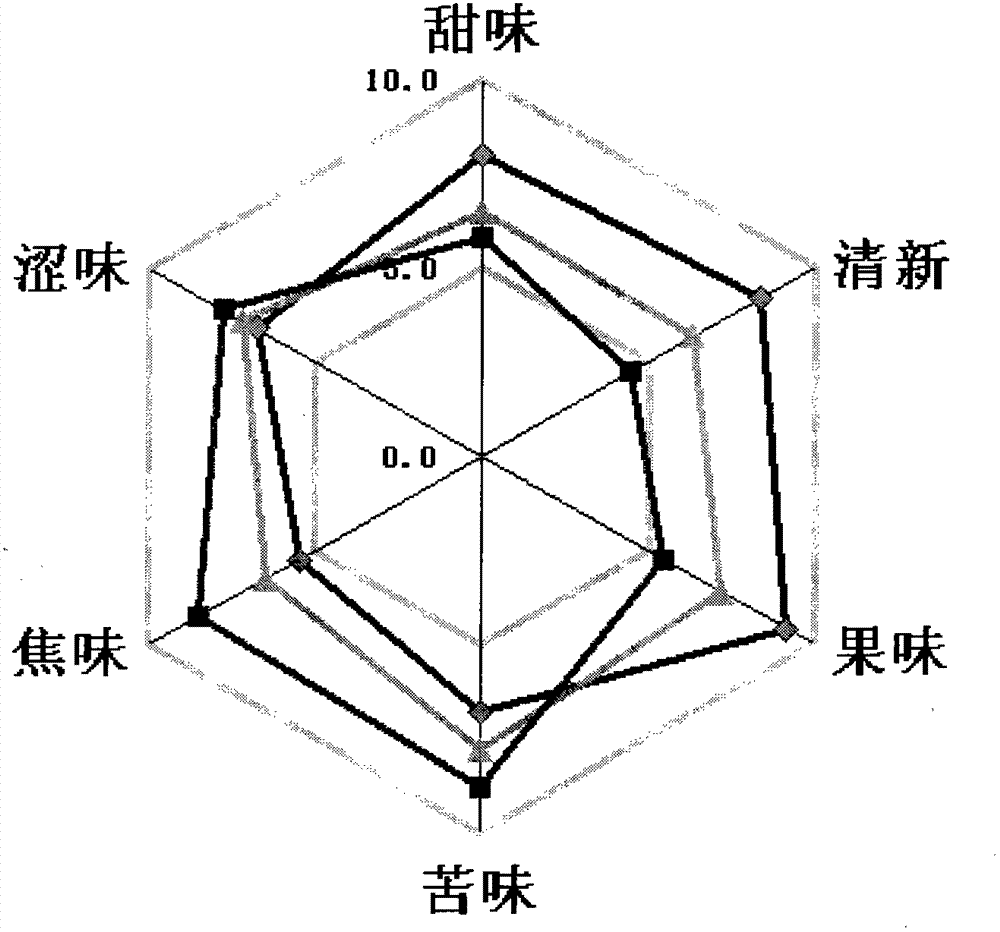

Two-stage green coffee bean baking method

PendingCN111264660AEasy to keepGood bodyCoffee roasting methodsRoasted coffee treatmentEngineeringGreen coffee

The invention discloses a two-stage green coffee bean baking method. The method comprises the following steps: S01, first-stage baking: performing first-stage baking on green coffee beans at a temperature close to a bean explosion temperature to obtain baked beans, wherein a first-stage baking temperature is 170-180 DEG C, and first-stage baking time is 8-10 minutes; S02, cooling: taking out the baked beans in the step S1, and allowing the baked beans to stand; S03, carrying out second-stage baking: carrying out second-stage baking on the cooled baked beans at 210-220 DEG C for 6-8 minutes toobtain roasted beans; S04, cooling and bean waking; and S05, packaging. The roasted beans obtained by the method have less acerbity and less other foreign flavors generated during primary processing,better retain original flower fragrance, fruit fragrance and sweet aftertaste of coffee, and are better in mellowness and more popular with the public in mouth feel.

Owner:YUNNAN DEHONG TROPICAL AGRI RES INST

Lactic acid fermentation broth of loquat juice and preparation method thereof

InactiveCN101606739BSolve the technical problems of easy browningPrevent discolorationFood preparationLactobacillusFruit juice

The invention provides a lactic acid fermentation broth of loquat juice and a preparation method thereof, comprising lactic acid fermentation broth of loquat juice which is not added with milk powder and is fermented directly by using the lactic acid bacteria and a preparation method thereof. The invention solves the defects that in the prior art, the juice of the loquat product has poor fruity, single flavor and defects that health care function and the nutrient components can not be absorbed fully by the body and the like, adopts loquat juice as raw material, adds the lactic acid bacteria fermenting agent, adjusts and controls fermentation conditions, carries out fermentation under moderate temperature condition and prepares the lactic acid fermentation broth with lactic acid fermentation flavor. The invention does not need to add milk powder, maintains inherent nutrient components of loquat, endows the loquat juice of the lactic acid fermentation broth with unique nutrition and flavor, is a high-quality novel loquat juice fermenting beverage and enriches the varieties of the lactic acid fermentation beverage.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Unadulterated raspberry wine and production method thereof

InactiveCN106281865ARetain natural colorFruityDigestive systemAlcoholic beverage preparationFiltrationOfficinalis

The invention discloses unadulterated raspberry wine and a production method thereof. The unadulterated raspberry wine is prepared from the following effective components in parts by weight: 84000 -86000 parts of raspberry fruits, 14000-15000 parts of honey, 40-100 parts of fructus schisandrae chinensis and 40-100 parts of mangnolia officinalis. The brewing method comprises the steps of removing stems of screened raspberry berries, crushing, squeezing, and pouring into a fermentation tank, carrying out alcoholic fermentation at low temperature, clarifying to remove sediments, carrying out membrane filtration at low temperature, blending honey and traditional Chinese medicines, carrying out secondary clarification and filtration, packaging and sterilizing to finally obtain the unadulterated raspberry wine. According to the unadulterated raspberry wine and the production method disclosed by the method, the honey and traditional Chinese medicines are blended and added, and a special fermentation means is utilized, so that the unadulterated raspberry wine has pure flavor and strong fruit taste, and people can absorb various nutrient substances in the raspberry more easily.

Owner:河北祥佰瑞树莓酒业有限公司

Drying method of momordica grosvenori and momordica grosvenori obtained by using same

ActiveCN102125249BRegular shapeFruit shape is beautifulDigestive systemRespiratory disorderMomordicaGlycoside formation

The invention discloses a drying method of momordica grosvenori and the momordica grosvenori obtained by using the same. The drying method comprises the steps of: cleaning the fresh momordica grosvenori, deactivating enzyme, putting the enzyme-deactivated momordica grosvenori into a freeze dryer, reducing the temperature from -40 DEG C to -60 DEG C, controlling a temperature reducing process within 1-3h, rising the temperature to -25 DEG C to -15 DEG C by the temperature rising speed rate of 1.2-7.5 DEG C / h, rising the temperature to 20-25 DEG C by the temperature rising speed rate of 3.5-10 DEG C / h, and keeping the temperature for 4-8 hours. Compared with the prior art, the enzyme of the fresh momordica grosvenori is deactivated to restrain the activity in the enzyme, and the momordica grosvenori is dried in a freezing way under a special temperature condition to obtain the dried momordica grosvenori which is integrated in shape and beautiful, and has the same color and luster as thefresh momordica grosvenori; the momordica grosvenori is good in mouthfeel, the special fruity of the fresh momordica grosvenori is kept, and the conservation rate of the momordica glycosides V in thedried momordica grosvenori is high; and the invention is simple and controllable in technology, low in energy consumption, and less in the loss of nutrition constituents in the fresh momordica grosvenori.

Owner:GUILIN NATURAL INGREDIENTS CORP

Persimmon enzyme alcoholic drink mixed with fruit juice and preparation method thereof

The invention discloses persimmon enzyme alcoholic drink mixed with fruit juice, belongs to the technical field of processing of fruit wine, and solves the problem that the flavor and nutritive valueof persimmon wine are affected by persimmon wine brewing in the prior art. According to the technical scheme, the persimmon enzyme alcoholic drink mixed with fruit juice comprises the following raw materials: persimmon, pectin, enzyme compound bacteria, a tartaric acid solution, pectase, citric acid and honey. The persimmon enzyme alcoholic drink mixed with fruit juice prepared by the preparationmethod is high in yield, the fermented persimmon wine is full-bodied in taste, the taste of the wine is improved by honey fermentation and conversion, the produced persimmon wine is full-bodied in taste, a secondary fermentation temperature is controlled to be 25-28 DEG C, the fruity of the persimmon is maintained favorably, meanwhile, the fermentation time is prolonged, the persimmon wine tastesabundantly, and is prepared from persimmons, honey and the like as auxiliary materials, and the persimmon enzyme alcoholic drink mixed with fruit juice contains vitamin, amino acid, polysaccharide substances and microelement such as iodine, zinc, iron and calcium, and has quite high economic value and nutritive value.

Owner:山东恒糅酒业有限公司

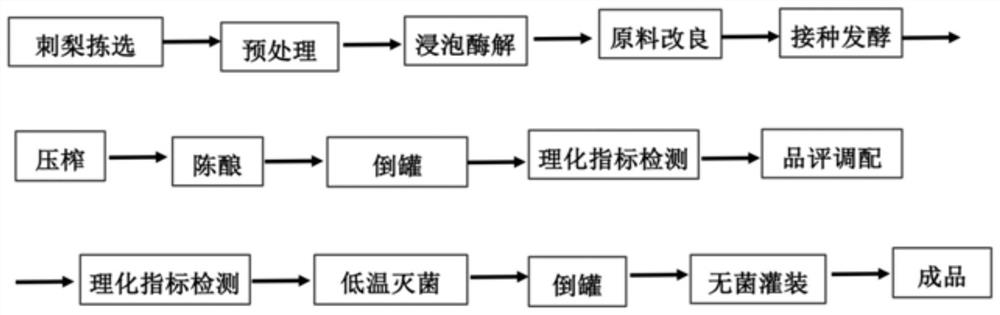

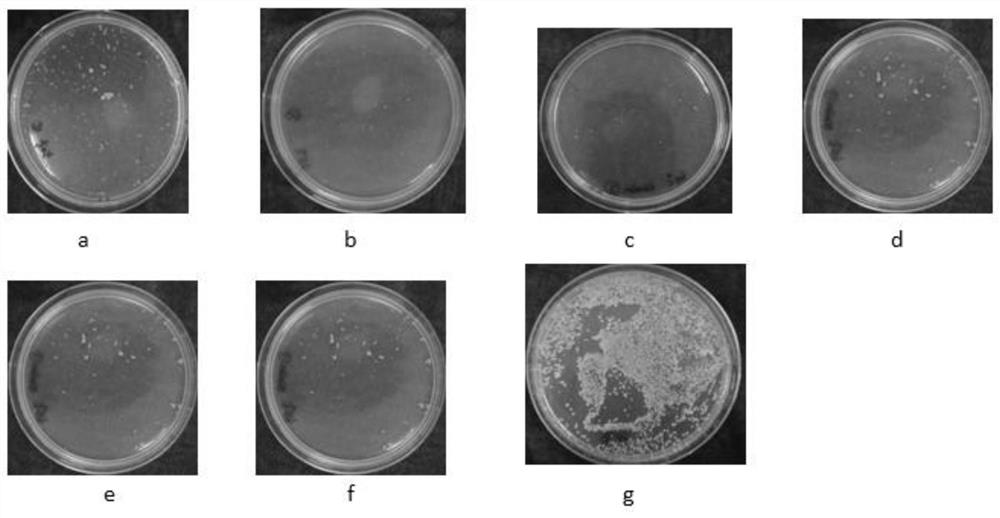

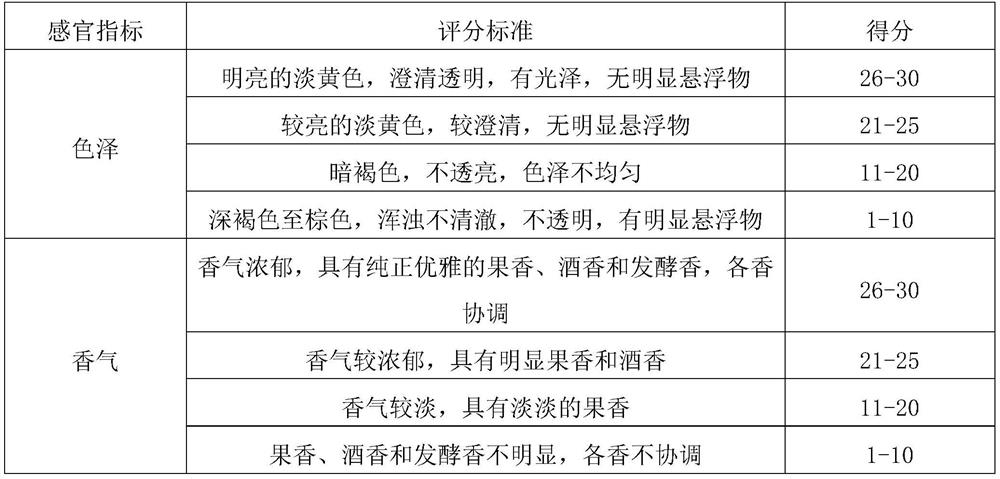

Low-temperature preparation method of roxburgh rose fermented wine

InactiveCN113549517AThe wine is clear and transparentFruityAlcoholic beverage preparationMicroorganism based processesBiotechnologyFruit wine

The invention discloses a low-temperature preparation method of roxburgh rose fermented wine, and belongs to the technical field of wine brewing. The method comprises the following steps of (1) preparing roxburgh rose leachate; (2) improving the roxburgh rose leachate; (3) performing inoculating and fermenting; (4) performing low-temperature fermentation; (5) monitoring specific gravity; (6) stopping fermentation; and (7) sterilizing. The roxburgh rose fruit wine prepared by the method is transparent yellow, clear and transparent in wine liquid, rich in fruit fragrance, rich in fermentation fragrance, full in wine body, balanced in acerbity, rich in nutrition, simple in brewing method, low in cost and easy to industrialize.

Owner:GUIZHOU INST OF TECH

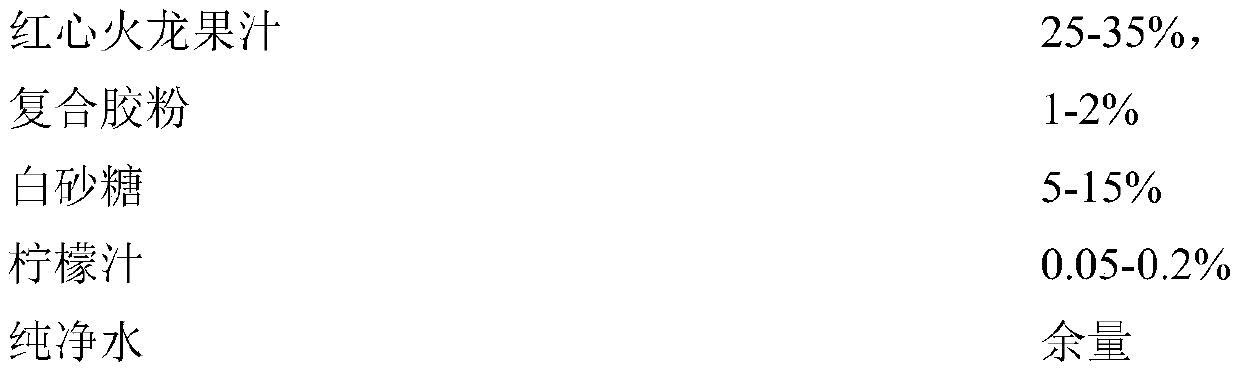

Red pitaya jelly and preparation method thereof

The invention relates to red pitaya jelly and a preparation method thereof. The jelly is characterized by being prepared from the following components by weight, wherein the composite gelatin powder is a mixture of carrageenan and sodium alginate in a weight ratio of 7:3. The preparation method of the red pitaya jelly comprises the following steps: cleaning red pitaya, draining water, freezing thewhole fruit at subzero 18- 20 DEG C for 24 hours or longer, taking out the red pitaya after the red pitaya is frozen in a hard state, placing the red pitaya in a stainless steel tank, and performingheating in water bath at 65-70 DEG C for unfreezing; performing filtering to remove peel and residues to obtain red pitaya juice.

Owner:ZHEJIANG WANLI UNIV

Preparation method of fried dried apples

InactiveCN104605282ACrispy tasteSimple production processFood ingredient functionsFood preparationProcess engineeringCitric acid

The invention relates to a preparation method of fried dried apples. The method is characterized by comprising the following steps: (1) selecting fresh apples, soaking the apples into clear water, and then cleaning the surfaces of the apples with water; (2) removing the peels of the apples, removing pulp, and cutting the apples into slices with uniform sizes; (3) blanching the slices with hot water with the temperature of 95 DEG C for 35 minutes, then cooling in time, and draining off the water; (4) preheating a frying pan up to 110 DEG C, and sealing and exhausting after a raw material basket is put into the frying pan; maintaining the temperature to be 90-100 DEG C, gradually increasing the vacuum degree to 0.09Mpa from 0.06Mpa, and maintaining for 10 minutes; maintaining the rotation of the basket during frying; (5) controlling the rotating speed to be 1000-1200 revolutions / minute under the condition that the vacuum degree is 0.06Mpa for 2 minutes; (6) spraying the mixed liquid of citric acid and sugar onto the crisp slices to improve the flavor; and (7) drying in the air and bagging.

Owner:袁晓健

Movable suspending type three purpose duck roasting oven of coke, fuel oil and gas

InactiveCN1586208ASwivel operation is convenientUniform donenessBaking ovenProcess engineeringFuel oil

The movable duck roasting oven consists of ten parts of temperature maintaining roaster, three-purpose oven, rotary duck hanger, oil accepting sump, temperature display, lighting lamp, blower, moving unit, electronic igniting switch and high pressure oil gas controlling valve. The three-purpose oven is used to burn coke, diesel oil, natural gas or coal gas to replace fruit wood, and the roaster is heated with the heat radiating cavity and the fume pipe of stainless steel. The present invention has the advantages of low cost, great heat amount, easy control, good look of the roasted duck, no fume pollution, etc. and may be also used in roasting sucking pig, whole sheep, etc.

Owner:张黑喜

A kind of brewing method of low-alcohol blueberry health wine

ActiveCN105368631BDeep colorStrong aromaAlcoholic beverage preparationMicroorganism based processesHydrolysisHigh heat

The invention discloses a brewing method of low-alcohol blueberry health wine. The method comprises the steps of selecting and processing blueberries, tea pretreatment, raw material blending, ethanol fermentation, aging, clarification and stabilization treatment and the like. The method uses the blueberry of the preferred Blue Rain variety as the raw material, and simultaneously adds tea extract, prebiotics and soluble dietary fiber; through impregnation of the original pulp, high-temperature enzymatic hydrolysis, high-temperature start-up, mixed bacteria synergy, and low-temperature long-term fermentation to obtain low-temperature Alcoholic blueberry wine; Microwave-assisted aging at low temperature accelerates wine body maturation and improves fruit wine quality; Through clarification and stabilization treatment, the wine body obtains higher clarity and maintains a stable state for a long time; Improves the taste of the wine by adding functional sweeteners, Increase its health care function at the same time. According to this process, a high-quality, low-alcohol blueberry fruit wine with good color, aroma and taste, which integrates nutrition and health care can be obtained.

Owner:HUANGSHAN BLUEBERRY ECOLOGICAL PARK CO LTD

Preservation method of Syzygium samarangense

ActiveCN103493880BImprove stress resistanceResist damageFruits/vegetable preservation by heatingBiotechnologyPreservative

The invention relates to a fresh-keeping method of lotus mist, which combines heat stress and a unique formula of lotus mist preservative, and the two cooperate with each other to achieve the effect of mutual promotion, which effectively prolongs the fresh-keeping period of lotus mist fruit. It reduces the occurrence of fruit rot during the fresh-keeping period, and can also well maintain sensory qualities such as fruity aroma, fruity taste, and skin gloss. The above effects are unexpected to those skilled in the art.

Owner:南通市通州区十总晨友农产品有限公司

Pickled compound fruit-flavored red jujube and manufacture method thereof

InactiveCN108606285AIncrease fruity aromaRich varietyFruit and vegetables preservationFood ingredient as taste affecting agentPEARPapaya family

The present invention discloses a pickled compound fruit-flavored red jujube. The pickled compound fruit-flavored red jujube comprises the following components in parts by weight: 70-80 parts of treated red jujubes, 20-25 parts of pear blocks, 15-20 parts of grapefruit peels, 15-20 parts of papaya strips, 10-15 parts of fruit-flavored pressure sensitive microcapsules, 5-8 parts of nutrient particles, 5-8 parts of compound non-metallic particles, 25-30 parts of honey, 10-15 parts of fruit vinegar and 10-15 parts of antiseptic microcapsules. The pickled compound fruit-flavored red jujube is richin nutrients, enriches the variety of food, and greatly meets needs of consumers.

Owner:ZHONGXI TIANJIN JUJUBE TECH ENG CENT

A brewing process of chrysanthemum dry white wine added with glutathione

ActiveCN104560487BImprove reducibilityAROMA CHARACTER PROTECTIONWine preparationVitis viniferaEmulsion

The invention discloses a process for brewing chrysanthemum dry white wine added with glutathione, and relates to the technical field of wine brewing. According to the process, the glutathione is added twice during the period from pickling grapes to forming a fine product; the glutathione is added for the first time in the clear grape juice fermentation process; the glutathione is added for the second time after apple emulsion fermentation is ended; and chrysanthemum is added in the clear grape juice fermentation process, so that the fruit aroma of the dry white wine is fully reserved; and the dry white wine has the efficacies of the chrysanthemum, and is relatively beneficial to human health.

Owner:HEBEI ACAD OF FORESTRY SCI

Brewing method of mulberry wine with low alcohol concentration

InactiveCN110760419AImprove accuracyStable and stableAlcoholic beverage preparationMicroorganism based processesBiotechnologyPectinase

The invention provides a brewing method of mulberry wine with low alcohol concentration. The brewing method of the mulberry wine with low alcohol concentration comprises the following steps: (1) selecting raw materials; (2) carrying out squeezing and crushing; (3) carrying out treatment with pectinase; (4) carrying out fermentation, and terminating the fermentation by adding a yeast inhibitor, namely cinnamic acid or potassium cinnamate, at a dosage of 200-880 mg / L or adding the yeast inhibitor in coordination with SO(2); (5) carrying out separating and squeezing; (6) adding gel so as to be subjected to clarification; (7) carrying out freezing; and (8) obtaining a finished product. The brewing method of the mulberry wine with low alcohol concentration is scientific, rational, simple in steps, and easily controllable in conditions. Moreover, a fermentation inhibition technology combining the cinnamic acid or the potassium cinnamate with low temperature is creatively adopted; and fresh mulberry fruits, rather than mulberry fruit concentration, are used without water, so that fermentation is carried out by adopting pure mulberry juice, thereby preserving nutrients, fruit aroma and taste of the mulberry fruits to a maximum extent. In addition, alcohol fermentation is carried out by completely using sugar in the mature mulberry fruits without addition of artificial sugar. The mulberry wine with low alcohol concentration brewed by the method has an alcohol concentration of 1-7% (v / v) and a total acid concentration of 4-10 g / L, and is brighly ruby in color, clear, transparent, free of suspension, free of precipitate, sour-sweet and palatable in taste, mellow in wine texture and suitable for various of populations, including the men, the women, the elderly and the children, todrink.

Owner:TIANJIN AGRICULTURE COLLEGE

Process for producing roxburgh rose distilled liquor

PendingCN112795454AEasy to makeEasy temperature controlDigestive systemAlcoholic beverage preparationBiotechnologyAcetic acid

The invention discloses a process for producing roxburgh rose distilled liquor, and particularly relates to the technical field of roxburgh rose distilled liquor production, which comprises the following specific steps: step 1, selecting raw materials; step 2, cleaning; step 3, crushing and canning; step 4, performing solid-liquid state fermentation; step 5, fermenting pure juice; step 6, fermenting and separating; and step 7, distilling. Beneficial substances such as roxburgh rose fruity aroma and polyphenol substances can be effectively extracted through solid-liquid state fermentation, the base wine with strong roxburgh rose fruity aroma and elegant fermentation aroma is obtained, the problem of abnormal fermentation such as acetic acid flavor is completely avoided, then pure juice fermentation is performed, freshness and elegance of fruity aroma are guaranteed, fruit aroma is thick and free of floating and impurity, and the output of methanol is greatly reduced, so that the methanol content is ensured to be within the national safety index; meanwhile, various superfluous higher alcohols which are not beneficial to aroma and taste are removed.

Owner:肖朝锋

Preparation method of aloe wine

InactiveCN100378212CAdapt to mild antibacterial biological propertiesHigh viscosityAlcoholic beverage preparationYeastFermentation

The present invention discloses a method for preparing aloe wine. Said method includes the following steps: peeling aloe, breaking and beating to obtain aloe pulp, adding compound enzyme to make degradation, regulating pH value, adding wine yeast to make fermentation, ageing, heat-insulating and filtering to obtain filtrate, so that an aloe wine can be made up.

Owner:广西亮亮食品集团有限公司

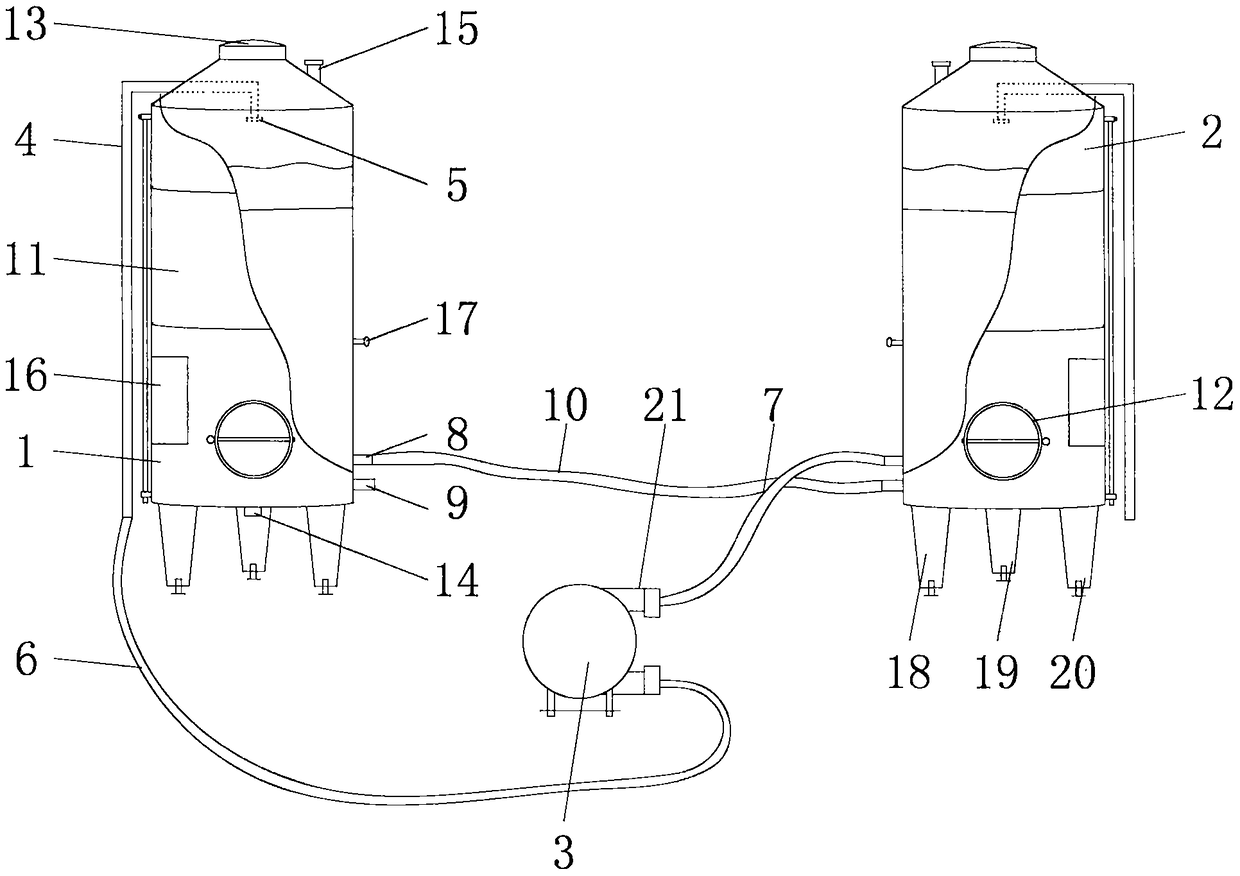

Red wine dual-temperature fermentation tank

The invention discloses a red wine dual-temperature fermentation tank, which comprises a first fermentation tank, a second fermentation tank and a peristaltic pump. The top of both the first fermentation tank and second fermentation tank is communicated with a circulating pipe. A sprayer is arranged inside both the first fermentation tank and second fermentation tank and is corresponding to the position of the respective circulating pipe. The first fermentation tank is communicated with the peristaltic pump through the corresponding circulating pipe and a first connecting pipe. The peristalticpump is communicated with the second fermentation tank through a second connecting pipe. The surface of both the first fermentation tank and second fermentation tank is provided with a clear juice opening and a cloudy juice opening. The peristaltic pump is communicated with the clear juice opening on the surface of the second fermentation tank through the second connecting pipe. According to theinvention, the tank capacity is fully utilized; automatic circulation is realized to reduce labor intensity; automatic production is achieved; higher quality wine is produced at lower cost; and the problem that utilization rate of fermentation tank capacity is low, labor intensity of operators is high and employment scale is high in the prior art is solved.

Owner:CHINA AGRI UNIV +1

Method for performing microwave drying on grosvener siraitia and grosvener siraitia dried by same

ActiveCN102125248BRegular shapeFruit shape is beautifulDigestive systemRespiratory disorderBiotechnologyEngineering

The invention discloses a method for performing microwave drying on grosvener siraitia and the grosvener siraitia dried by the same. The method comprises the following steps of: washing the grosvener siraitia completely and performing green-removing; punching a small hole on the top of the grosvener siraitia and the corresponding fruit navel at the bottom of the grosvener siraitia respectively; placing the punched grosvener siraitia into microwave drying equipment to dry for 8 to 10 minutes under the conditions of 2,400 to 2,500 MHz or 915 MHz and the temperature of between 50 and 60 DEG C; taking out the grosvener siraitia; placing the grosvener siraitia into the microwave drying equipment to dry for 8 to 10 minutes under the same conditions; taking out; cooling the grosvener siraitia atthe temperature of between 0 and 4 DEG C for 3 to 5 minutes; and repeating the drying and cooling processes for 5 to 6 times to obtain grosvener siraitia. Compared with the prior art, the method has the advantages of simple and easily controlled process, short drying time and low energy consumption. The obtained dried grosvener siraitia has a complete and attractive fruit shape, green color, goodmouthfeel and high retention rate of mogrosides V.

Owner:GUILIN NATURAL INGREDIENTS CORP

Fritillaria amur grape wine and preparation method thereof

InactiveCN107828578AMake up for the deficiency of low sugar contentGreat tasteMicroorganism based processesWine preparationFlavorGrape wine

The invention relates to fritillaria amur grape wine and a preparation method thereof. The preparation method includes following steps: preparing an amur grape fermentation matrix; preparing a fritillaria fermentation matrix; fermentating: a, well mixing the amur grape fermentation matrix and the fritillaria fermentation matrix according to a mass ratio of 150-250:1 to obtain a total fermentationmatrix; b, inoculating 15-30mg / L of brewer's yeast into the total fermentation matrix; c, allowing the total fermentation matrix to be in main fermentation at temperature below 23 DEG C for 10-15 days, and adding sugar accounting for 5-8% of mass of fermentation liquid during 6th-8th days of fermentation; d, after main fermentation is finished, filtering to remove residue to obtain fermented liquid, and performing post-fermentation and / or aging on the fermented liquid to obtain fritillaria amur grape wine. By the method, dissolving-out of active ingredients like alkaloid in fritillaria can beeffectively promoted, and taste and flavor of amur grape wine are improved.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Sterile cold-filling method of dry type goji berry fruit wine

ActiveCN102992254BScientificAvoid heat and cold shocksBottle-handling machinesFruit wineAdditive ingredient

The invention relates to a sterile cold-filling method of dry type goji berry fruit wine. The method is characterized by comprising the following steps: disinfecting and sterilizing all the devices and apparatuses contacted by dry type goji berry fruit wine in the process of filling firstly, then degerming and filtering the dry type goji berry fruit wine and finally completing processes of filling, corking and sealing of the wine liquid in a sterile and clean space, and thus completing sterile cold-filling. The invention provides a sterile cold-filling method of dry type goji berry fruit wine; the quality of the product is ensured by the sterile cold-filling; the wine is filled under a normal-temperature aseptic condition in cold-filling, so that the intrinsic colour and luster, fruity flavor, taste and nutritional ingredient are maintained at a maximum extent; the requirement on the bottle in the cold filling is low, so that the bottle body is prevented from bearing hot and cold shock; and consumption a great amount of steam is not needed in the cold filling, and only the normal-temperature filling is needed.

Owner:宁夏红枸杞产业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com