Low-temperature preparation method of roxburgh rose fermented wine

A technology for fermenting wine and prickly pear, which is applied in the field of wine making, and can solve problems such as unfavorable retention of functional components of prickly pear, unfavorable clarification of fermented wine in the later stage, and unfavorable industrial promotion, so as to achieve full body of wine, shorten fermentation cycle, and simple brewing method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

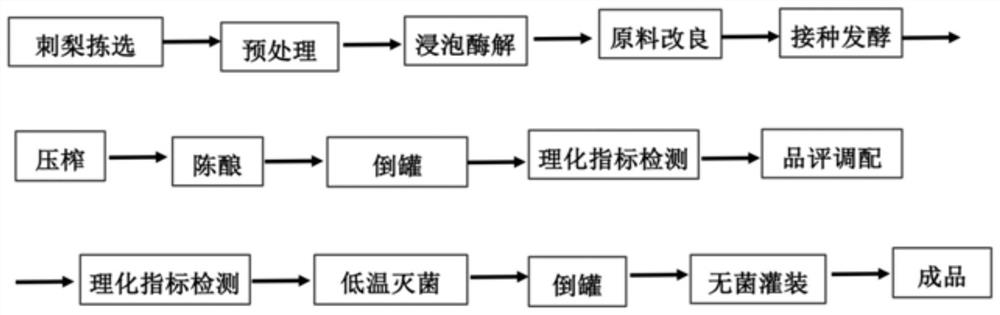

Method used

Image

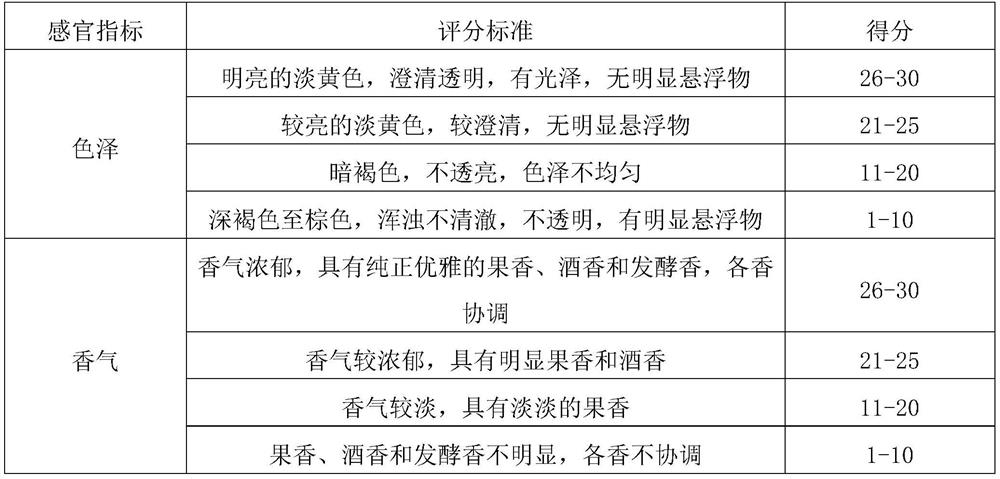

Examples

Embodiment 1

[0053] (1) Raw material selection: select nine-ripe roxburghii fruit;

[0054] (2) Raw material pretreatment: Add thorn pear and brewing water according to the mass ratio of 1:1, and use a screw press to crush the thorn pear to achieve the effect of breaking but not broken. Do not beat the pulp to obtain thorn pear juice, and Add pectinase to a concentration of 0.02g / L in the Rosa roxburghii juice, add potassium metabisulfite to a concentration of 50mg / L in the Rosa roxburghii juice, and let it stand at room temperature for 12h to obtain Rosa roxburghii extract;

[0055] (3) Raw material improvement: measure the pH and sugar content (Brix) of the leachate, adjust the pH to 3.6 with tartaric acid, adjust the sugar content to 24% with sucrose, stir evenly, and let stand for at least 12 hours to obtain the original juice of Rosa roxburghii;

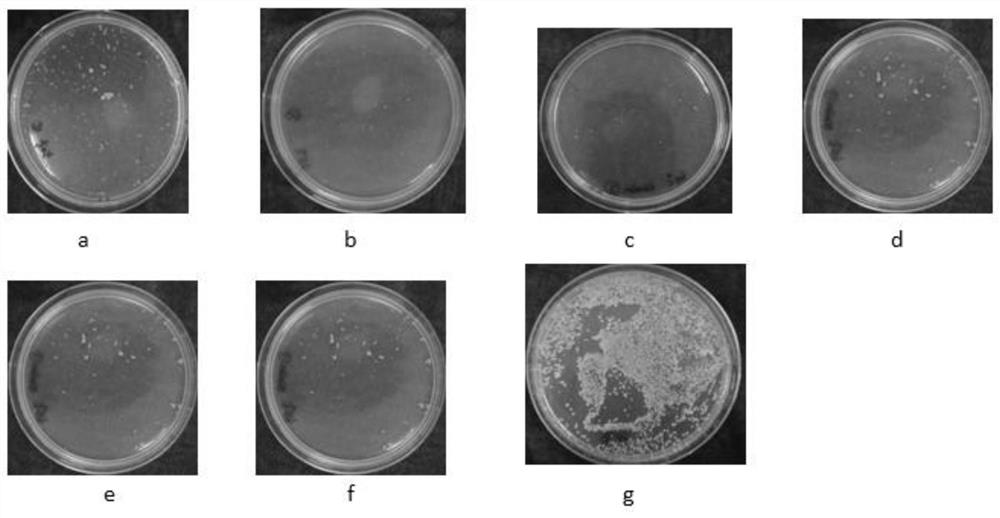

[0056] (4) Inoculation fermentation: add yeast and nutritional aid (main component is diammonium hydrogen phosphate) respectively in the ac...

Embodiment 2

[0064] (1) Raw material selection: select nine-ripe roxburghii fruit;

[0065] (2) Raw material pretreatment: Add thorn pear and brewing water according to the mass ratio of 1:2, use a screw press to crush the thorn pear to achieve the effect of breaking but not broken, do not beat the pulp, and add pectinase until The final concentration is 0.03g / L, potassium metabisulfite is added to a final concentration of 80mg / L, and it is allowed to stand at room temperature for 12 hours to obtain Rosa roxburghii extract;

[0066] (3) Raw material improvement: measure the pH and sugar content (Brix) of the leachate, adjust the pH to 3.3 with tartaric acid, adjust the sugar content to 20% with sucrose, stir evenly, and let stand for at least 12 hours to obtain the original juice of Rosa roxburghii;

[0067] (4) Inoculation fermentation: add yeast and nutritional aid (main component is diammonium hydrogen phosphate) respectively in the activation tank according to the ratio of S. Activate...

Embodiment 3

[0075] (1) Raw material selection: select nine-ripe roxburghii fruit;

[0076] (2) Raw material pretreatment: Add thorn pear and brewing water according to the mass ratio of 1:3, use a screw press to crush the thorn pear to achieve the effect of breaking but not broken, do not beat the pulp, and add pectinase until The final concentration is 0.04g / L, potassium metabisulfite is added to a final concentration of 100mg / L, and it is allowed to stand at room temperature for 12 hours to obtain Rosa roxburghii extract;

[0077] (3) Raw material improvement: measure the pH and sugar content (Brix) of the leaching solution, use tartaric acid to adjust the pH to 3.7, use sucrose to adjust the sugar content to 22%, stir evenly, and stand for at least 12 hours to obtain the original juice of Rosa roxburghii;

[0078] (4) Inoculation fermentation: add yeast and nutritional aid (main component is diammonium hydrogen phosphate) respectively in the activation tank according to the ratio of S....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com