Sterile cold-filling method of dry type goji berry fruit wine

A technology of aseptic cold filling and wolfberry fruit wine, which is applied in packaging, bottling machines, bottle filling, etc., and can solve problems such as damage, wine body aroma, adverse effects on color and taste, and complicated procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

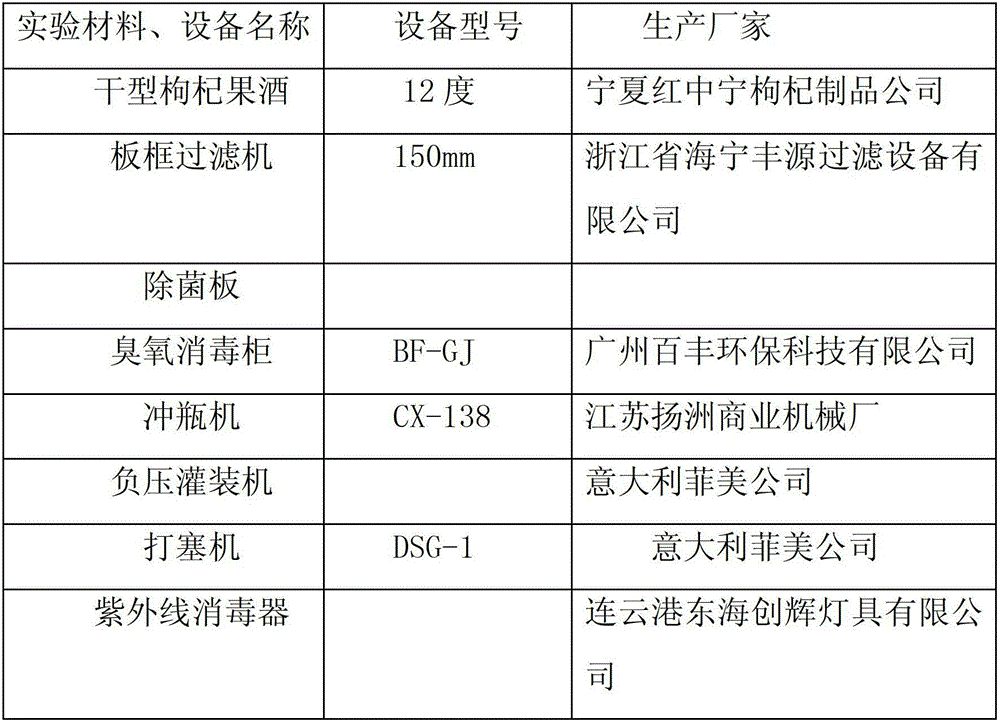

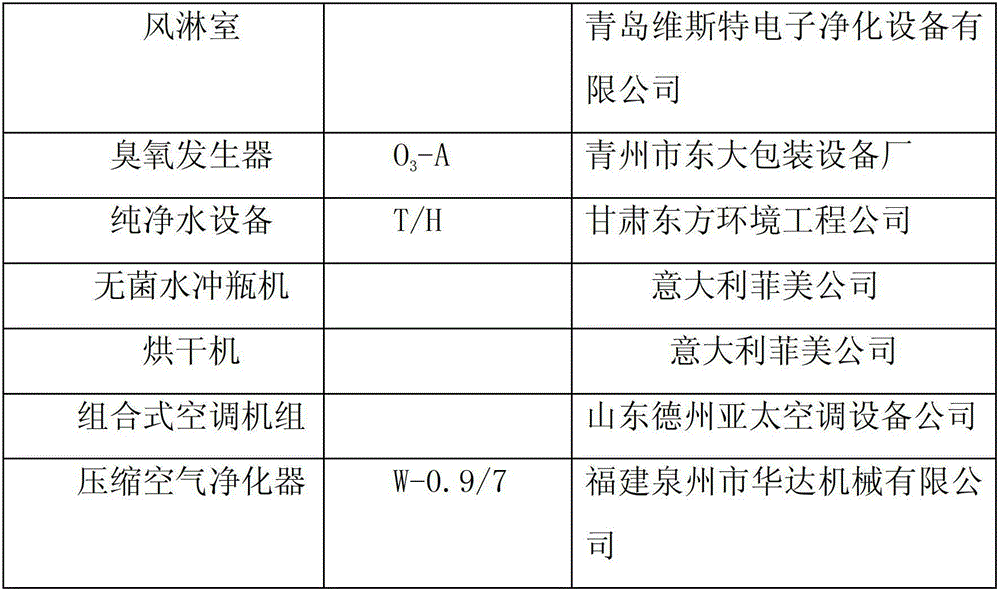

Examples

Embodiment 1

[0019] The aseptic filling room adopts 100-level purification. Turn on the ultraviolet lamp, turn on the air purification system and run it at a constant temperature of 18°C for 1h. Sterile air enters the filling chamber with a dense streamline diffuser and top air supply mode. After the sterile air passes through the spoiler, the air pressure is kept even in balance.

[0020] The ultraviolet lamp is turned off, and the operator wears clean clothes and enters the sterile area after being air showered for 30 seconds under the conditions of a filtration efficiency of 95% and a spray wind speed of 20m / s. Enter the empty bottle into the chlorine dioxide disinfectant with a concentration of 300PPM and fill the whole bottle with the disinfectant to drive out the air in the bottle. The inner and outer surfaces of the bottle must also be completely immersed in the disinfectant and stay for 10 seconds to ensure that the bacteria are completely killed , then pour the disinfectant in ...

Embodiment 2

[0022] The aseptic filling room adopts 100-level purification. Turn on the ultraviolet lamp, turn on the air purification system and run it at a constant temperature of 22°C for 1h. Sterile air enters the filling chamber with a dense streamline diffuser and top air supply mode. After the sterile air passes through the spoiler, the air pressure is kept even in balance.

[0023] The ultraviolet lamp is turned off, and the operator wears clean clothes and enters the sterile area after being air showered for 30 seconds under the conditions of a filtration efficiency of 95% and a spray wind speed of 20m / s. Enter the empty bottle into the chlorine dioxide disinfectant with a concentration of 200PPM and fill the whole bottle with the disinfectant to drive out the air in the bottle. The inner and outer surfaces of the bottle must also be completely immersed in the disinfectant and stay for 15 seconds to ensure that the bacteria are completely killed , Then pour the disinfectant in th...

Embodiment 3

[0025] The aseptic filling room adopts 100-level purification. Turn on the ultraviolet lamp, turn on the air purification system and run it at a constant temperature of 18°C for 30min. Sterile air enters the filling chamber with a dense streamline diffuser and top air supply mode. After the sterile air passes through the spoiler, the air pressure is kept even in balance.

[0026] The ultraviolet lamp is turned off, and the operator wears clean clothes and enters the sterile area after being air-drenched for 30 seconds under the conditions of a filtration efficiency of 99.99% and a spray wind speed of 15m / s. Enter the empty bottle into the chlorine dioxide disinfectant with a concentration of 300PPM and fill the whole bottle with the disinfectant to drive out the air in the bottle. The inner and outer surfaces of the bottle must also be completely immersed in the disinfectant and stay for 10 seconds to ensure that the bacteria are completely killed , Then pour the disinfecta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com