Vacuum reaction tank

A reaction tank and vacuum technology, applied in gas treatment, membrane technology, evaporation, etc., can solve the problems of low evaporation efficiency and inability to denitrify, and achieve the effect of improving sliding effect, avoiding tilting and bending, and enhancing mixing degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

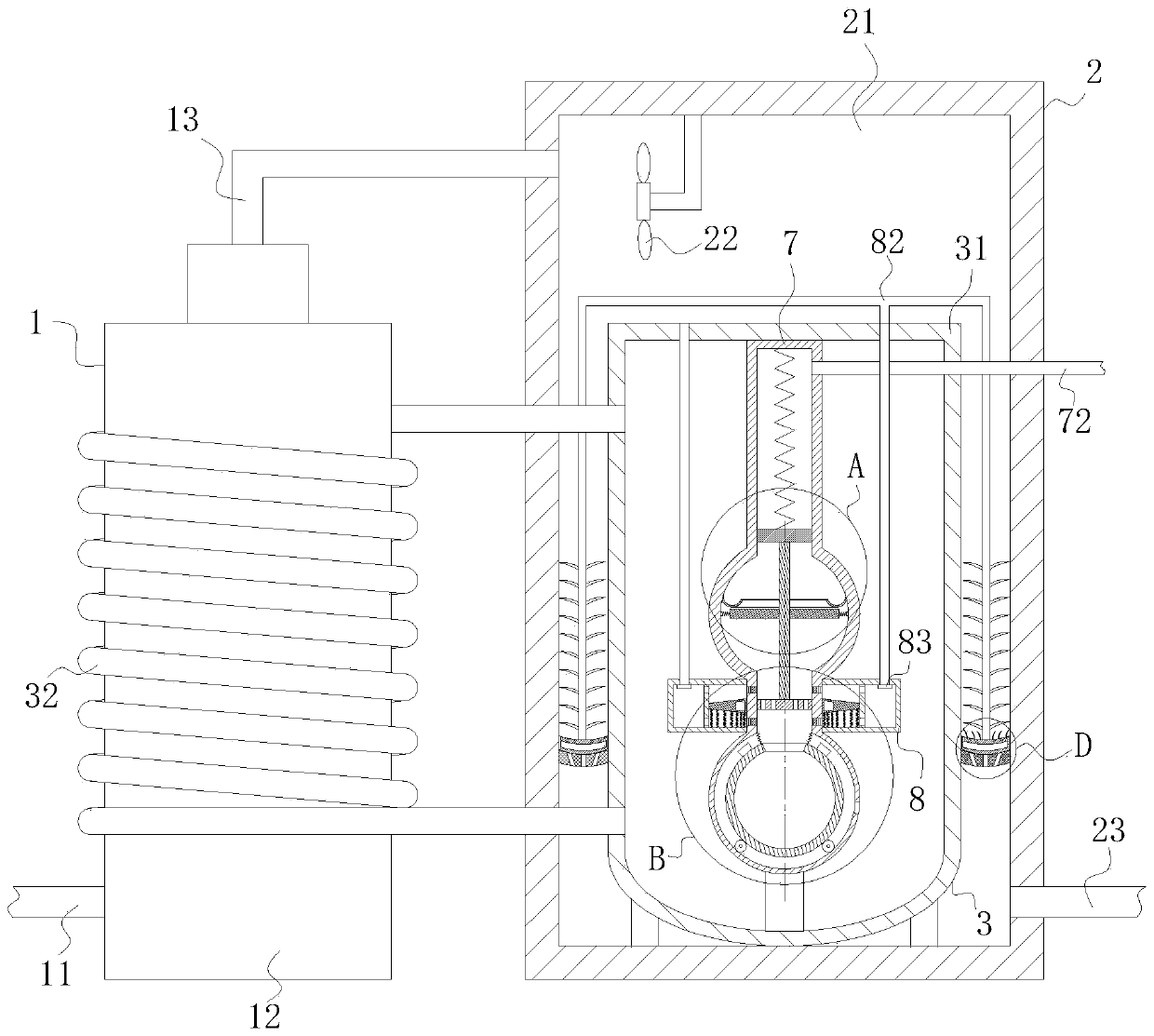

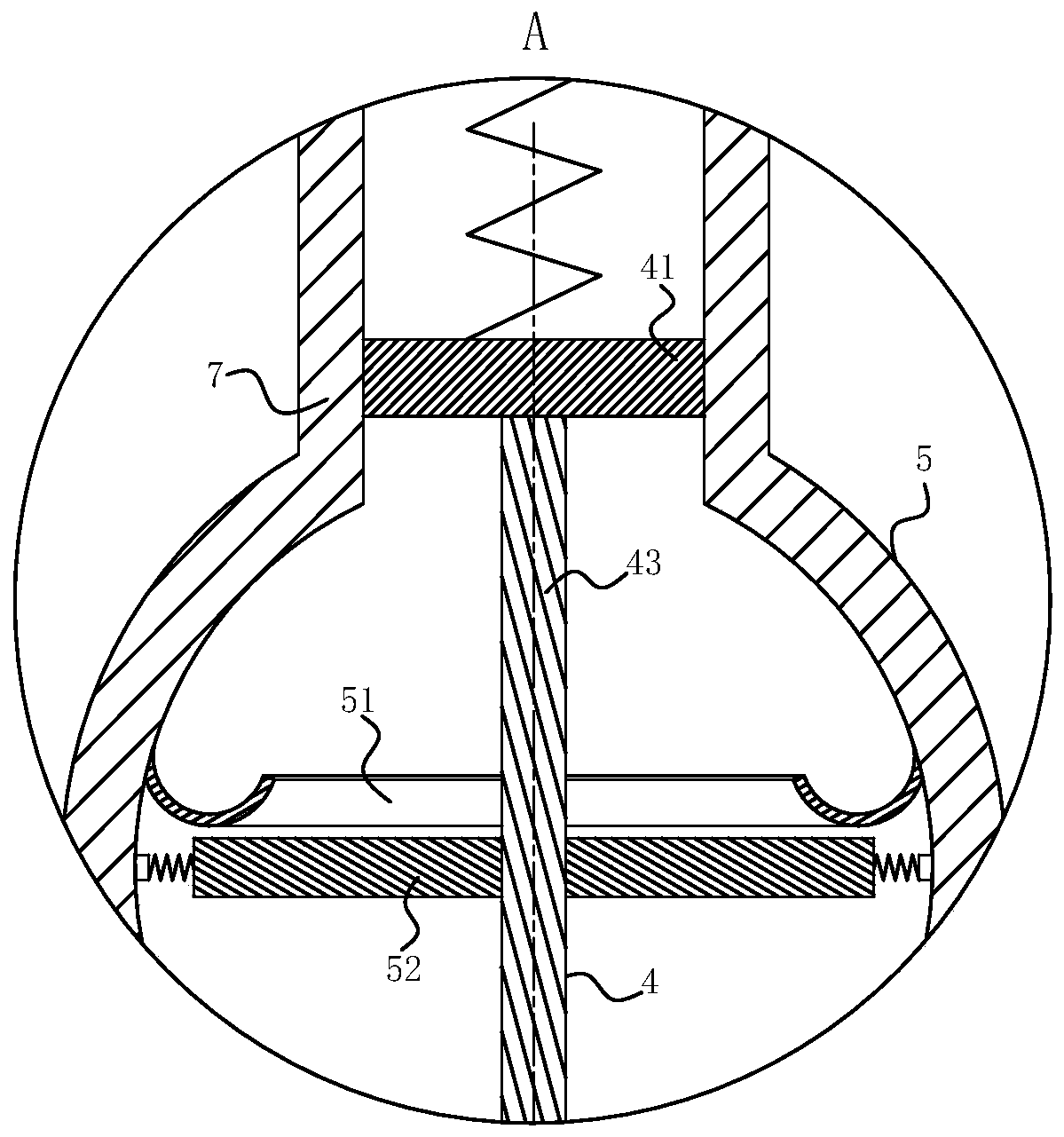

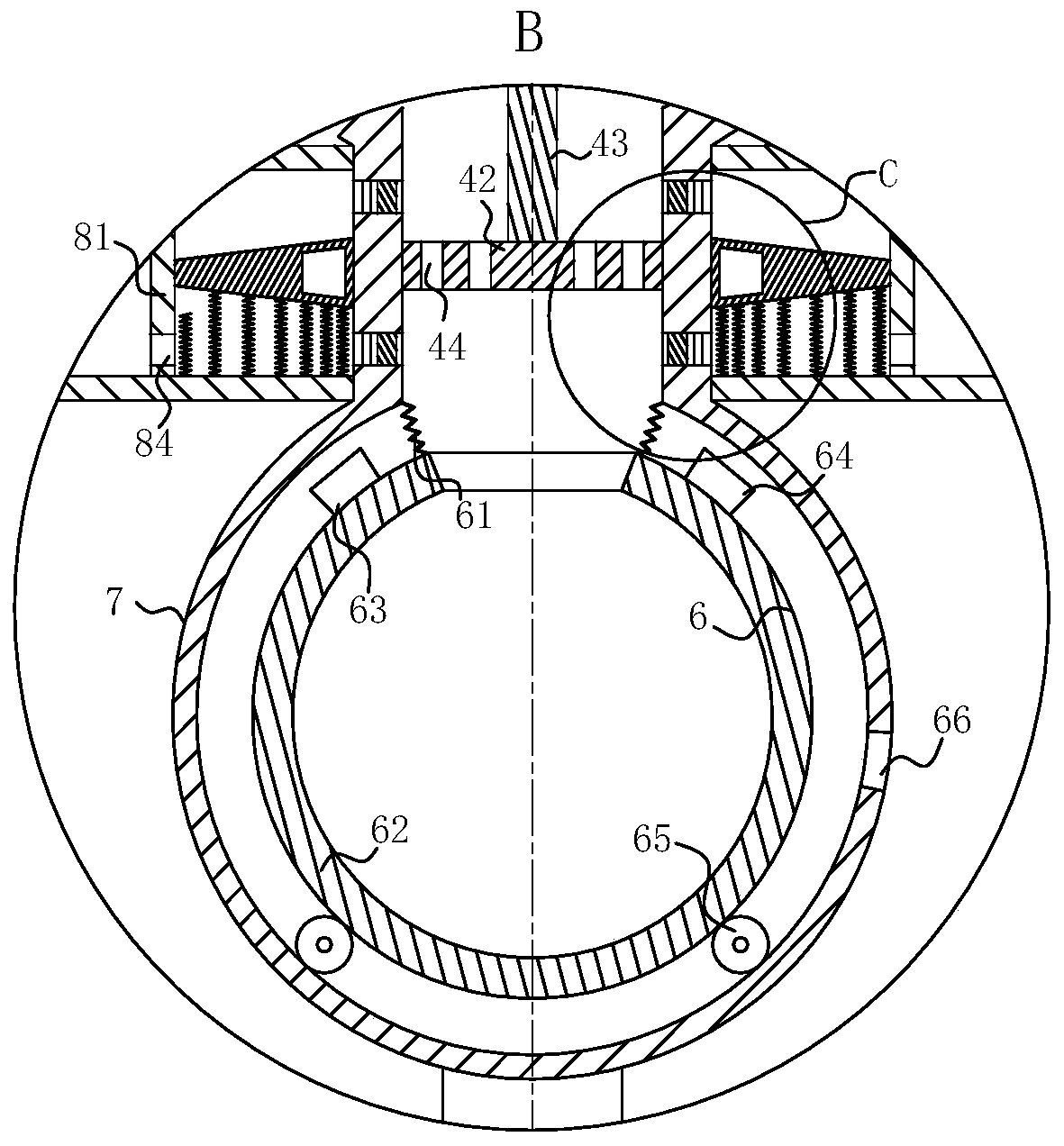

[0025] use Figure 1-Figure 5 A vacuum reaction tank according to one embodiment of the present invention will be described as follows.

[0026] Such as Figure 1-Figure 5 As shown, a vacuum reaction tank according to the present invention includes a smoke mechanism 1, a reaction mechanism 2, a heating mechanism 3, an intermittent cycle mechanism 4, a first evaporation mechanism 5 and a second evaporation mechanism 6; the smoke mechanism 1 includes an air inlet pipe 11, a smoke chamber 12 and a first air outlet pipe 13; the air inlet pipe 11 is fixedly connected to the lower wall of the left end of the smoke chamber 12; the left end of the first air outlet pipe 13 is fixedly connected to the smoke chamber In the upper end wall of 12, the right end of the first air outlet pipe 13 is fixedly interspersed with a reaction mechanism 2; the reaction mechanism 2 includes a reaction chamber 21, fan blades 22 and a second air outlet pipe 23; the reaction chamber 21 is located in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com