Composite flotation reagent for flotation separation of molybdenite and talc and flotation separation method

A technology of flotation reagents and separation methods, applied in flotation, solid separation, etc., can solve the problems of poor selectivity of organic inhibitors, limited effect of sulfonate, unsatisfactory effect, etc., to increase flotation rate and reduce flotation Recovery rate, the effect of achieving selective capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Preparation steps of flotation reagent:

[0055] 1. Add the flotation agent of the present invention to the reaction kettle in the order of deionized water-inhibiting component A-active component B-foaming agent, and heat to 50℃ and react under pressure for 1 hour to form a mixture. ;

[0056] 2. Place it in a mechanical stirrer at room temperature (25°C) and at room pressure for 2 hours to obtain a homogeneously mixed yellow viscous composite flotation reagent;

[0057] 3. Flotation is to mix the prepared composite flotation reagent with water at a ratio of 1:1000 and put it into an ultrasonic device for ultrasonic dispersion for 8 minutes and then add as needed to obtain a composite flotation reagent solution.

[0058] In the flotation process, the molybdenite mineral doped with talc is first pulped, aerated and stirred for 3 minutes, and then the required amount of the composite flotation reagent solution of the present invention is added.

[0059] As a preferred example, in ...

Example Embodiment

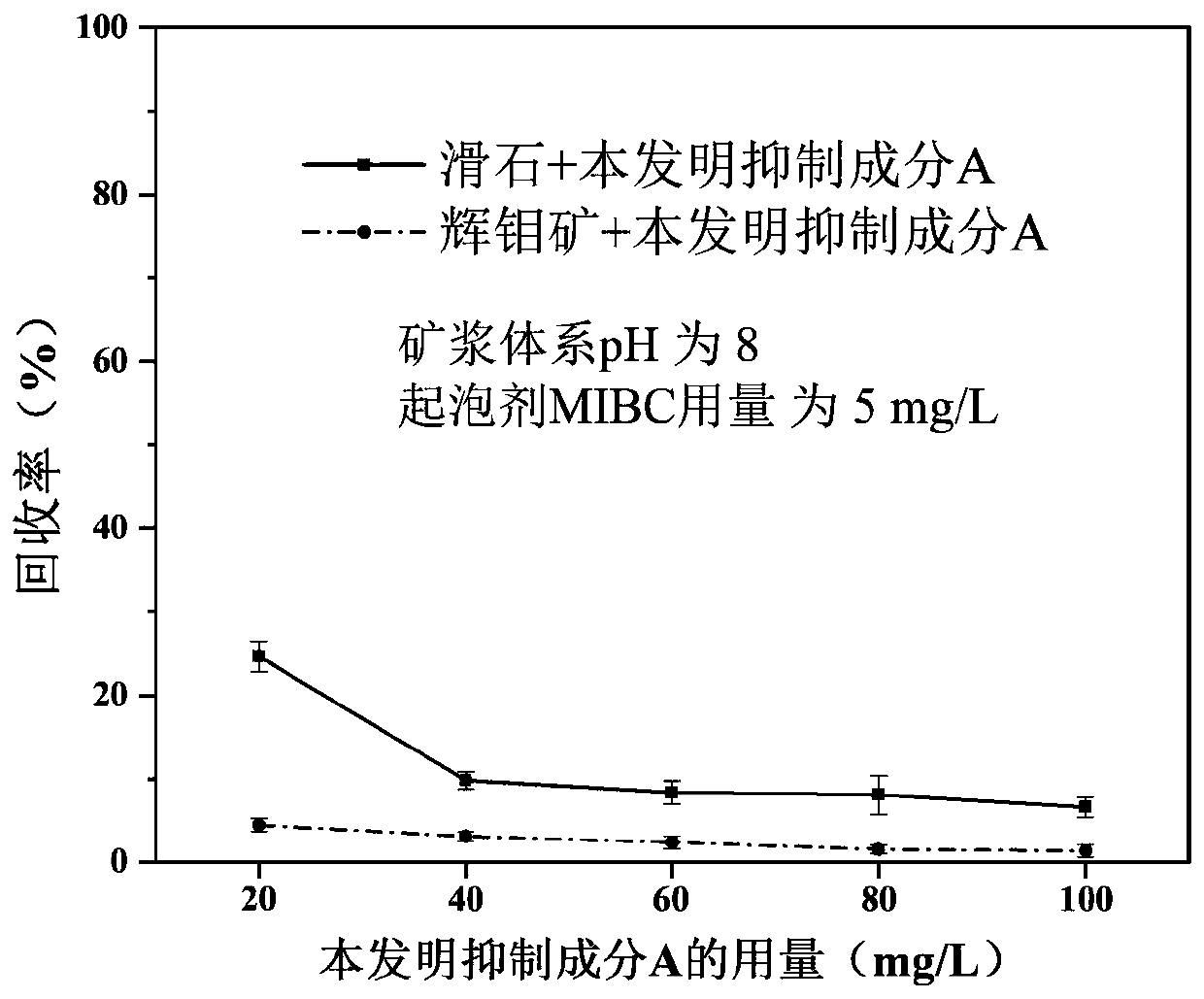

[0062] Example 1: (Case of the effect of inhibiting component A of the present invention)

[0063] Flotation reagent components used in Example 1:

[0064] Inhibition component A—divide into five groups, add 20; 40; 60; 80; 100mg / L,

[0065] No active ingredient B added,

[0066] Foaming agent—MIBC 5mg / L.

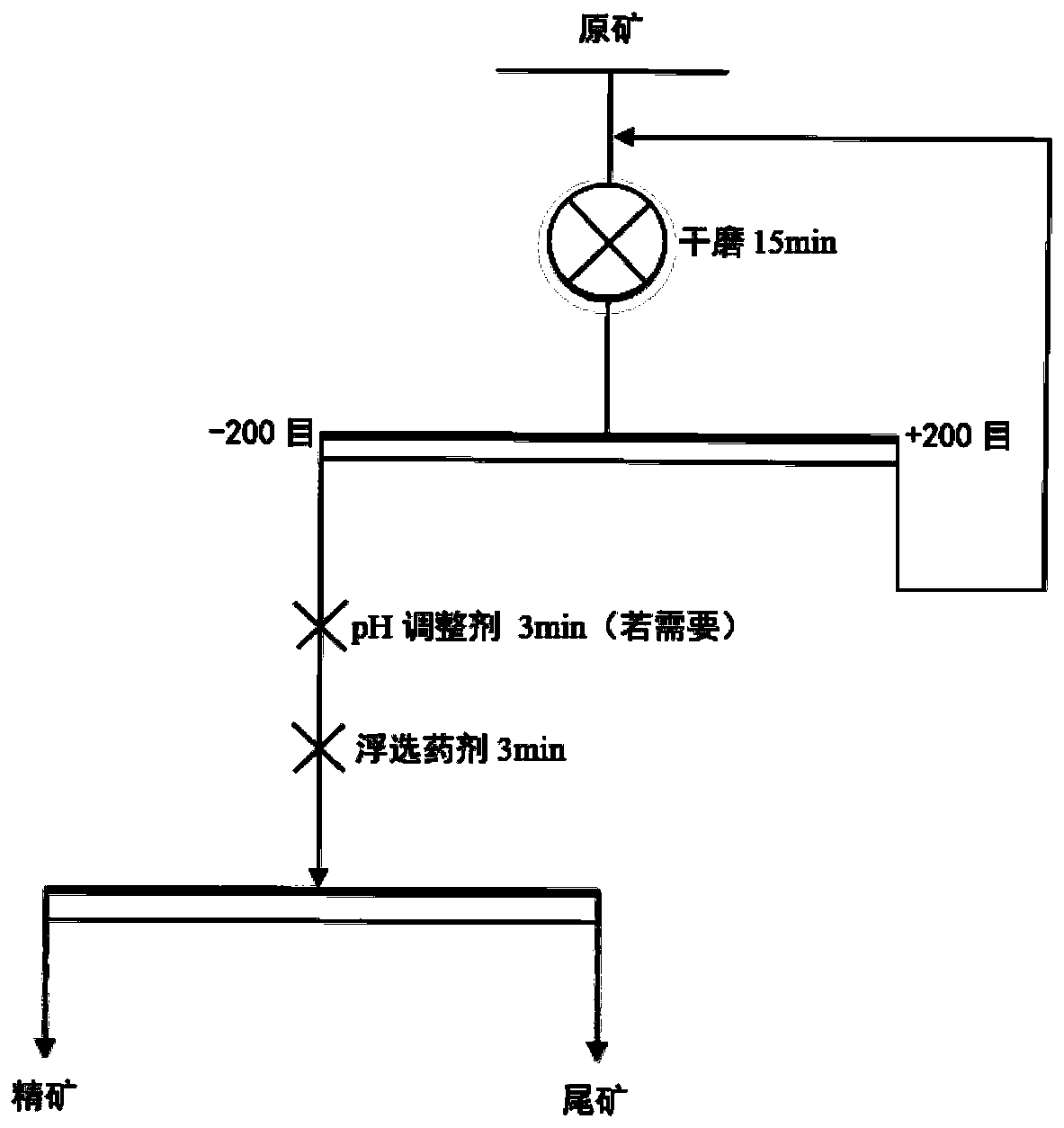

[0067] Flotation process:

[0068] Put 2g molybdenite or talc concentrate into a 40mL flotation tank, add appropriate amount of water, stir and aerate for 3 minutes to make the mineral slurry, add the flotation reagent solution described in Example 1, stir and aerate for 3 minutes, then scrape and The concentrate that the foam floats up together is scraped 20 times per minute for 3 minutes. The concentrate and tailings are dried and weighed separately. The recovery rate is calculated as shown in Table 1. figure 2 Shown ( figure 2 The average value of group 1, 2, 3 is used, and the upper difference is added as the error bar to draw), the flotation process is as follows figure 1 Show...

Example Embodiment

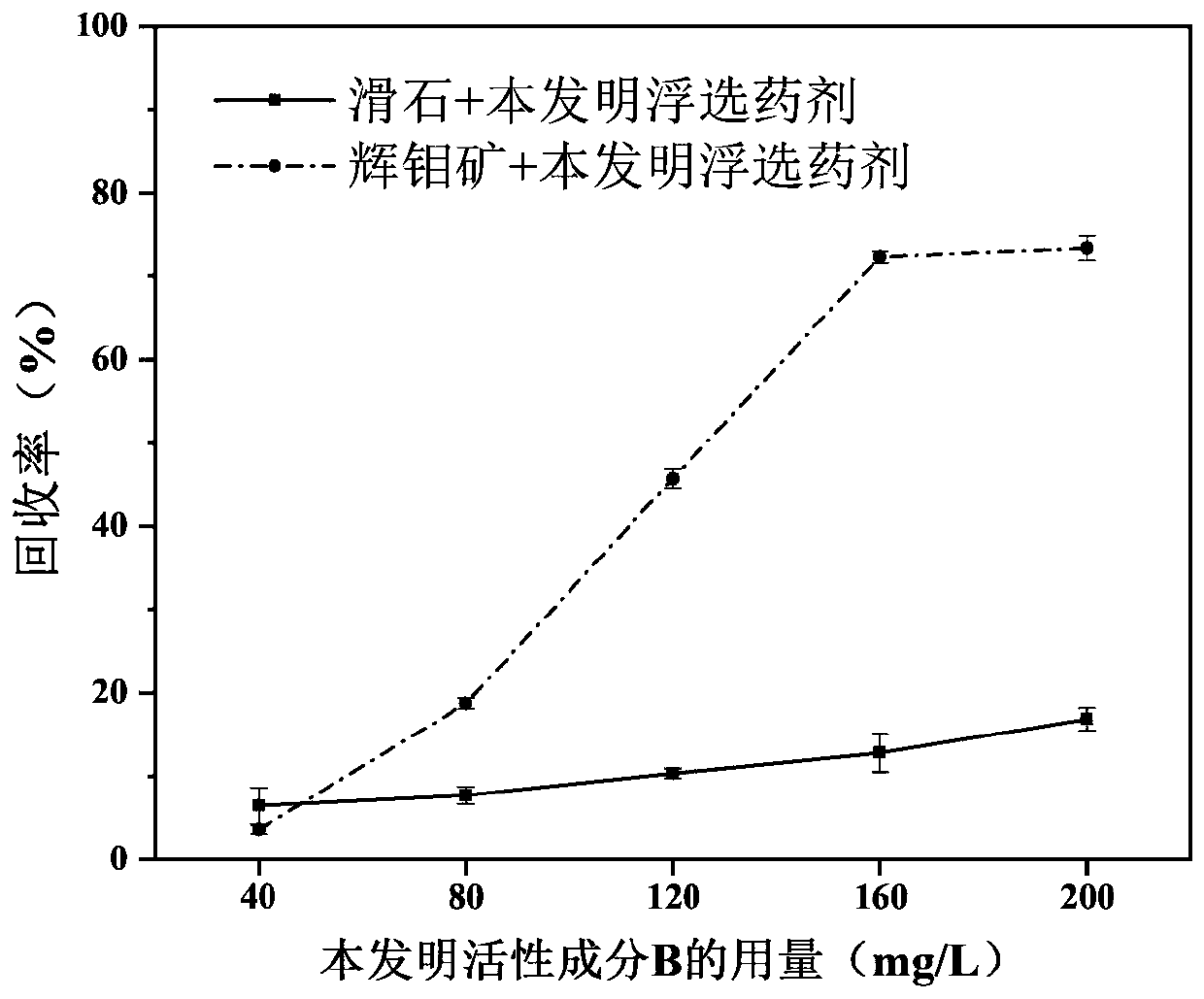

[0072] Example 2: (case of effect of active ingredient B of the present invention)

[0073] Flotation reagent components used in Example 1:

[0074] Inhibition component A—40mg / L,

[0075] Active ingredient B, sodium butyl xanthate (analytical pure, from Macleans Chemical Reagent Co., Ltd.), divided into five groups, added 40; 80; 120; 160; 200mg / L

[0076] Foaming agent—MIBC 5mg / L.

[0077] Flotation process:

[0078] Put 2g molybdenite or talc concentrate into a 40mL flotation tank, add appropriate amount of water, stir and aerate for 3 minutes to make the mineral slurry, add the flotation reagent solution described in Example 1, stir and aerate for 3 minutes, then scrape and The concentrate that the foam floats up together is scraped 20 times per minute for 3 minutes. The concentrate and tailings are dried and weighed separately, and the recovery rate is calculated as shown in Table 2. image 3 Shown ( image 3 The average value of group 1, 2, 3 is used, and the upper difference is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com