Outer die device capable of automatically opening and closing

A technology of automatic opening and closing, mold cylinder, applied in the direction of molds, etc., can solve the problems of high production cost, low safety, long curing time of concrete materials, etc., and achieve the effect of high reliability and large locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

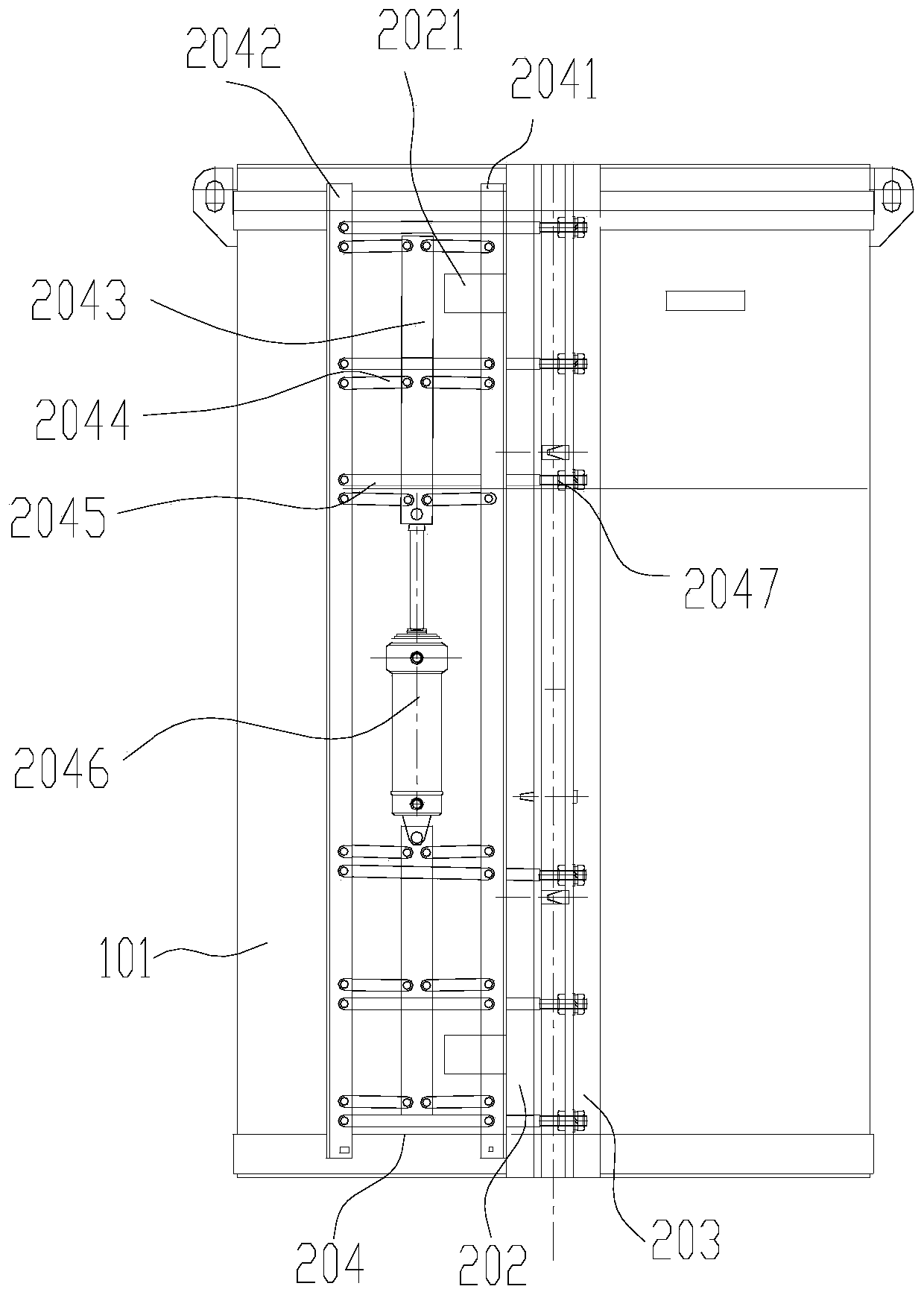

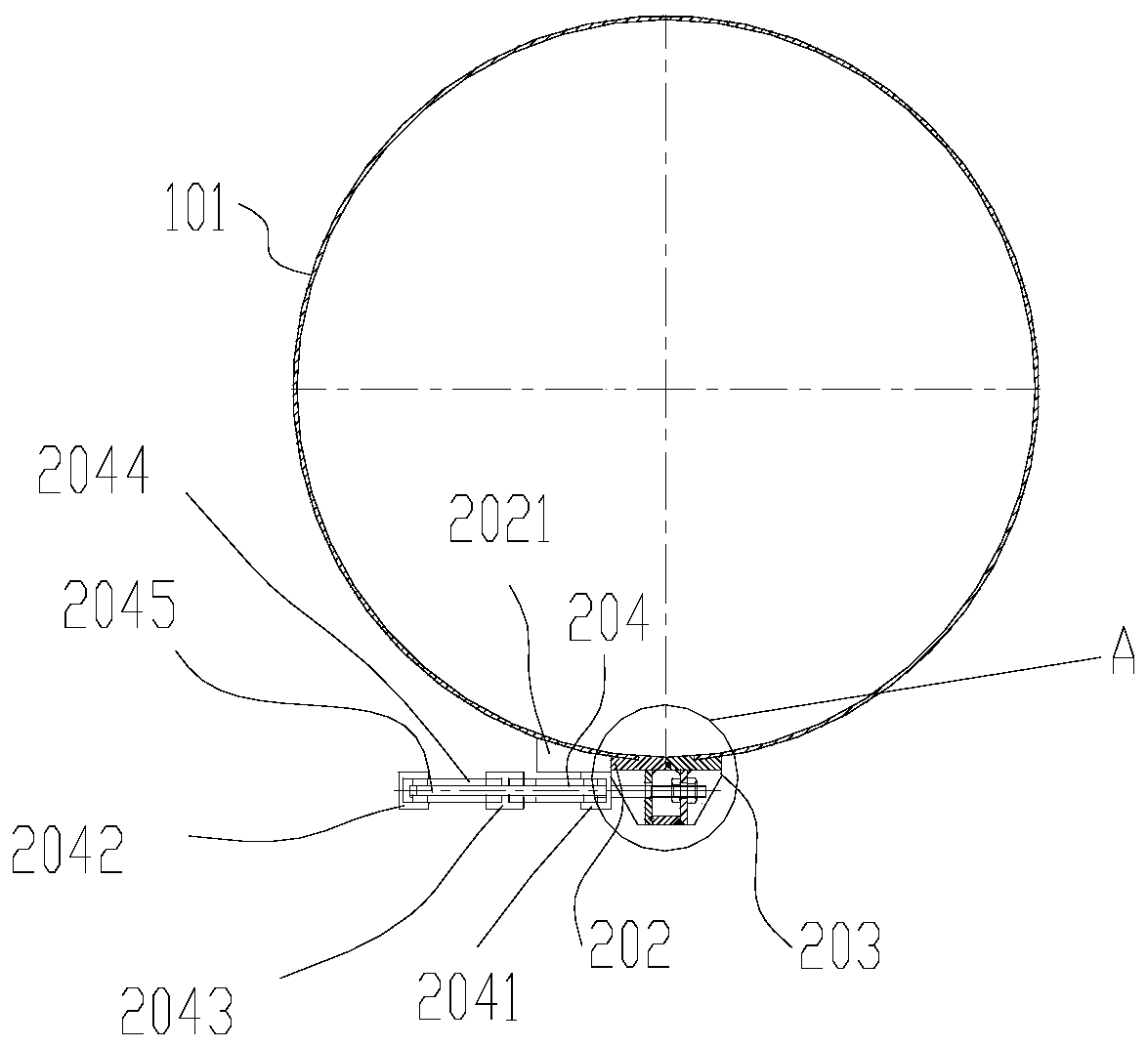

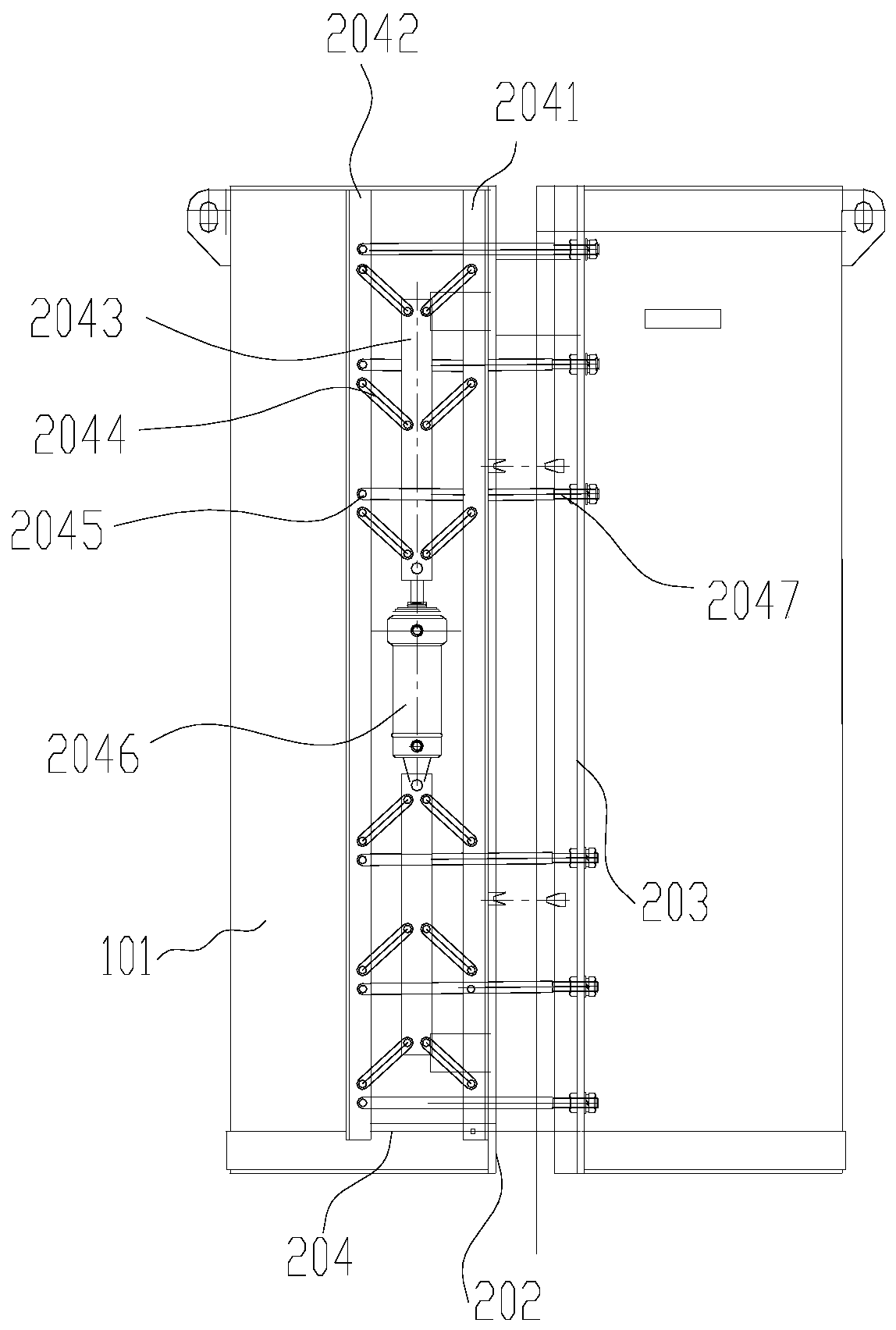

[0038] Attached below Figure 1-10 To further illustrate the present invention, it includes an outer mold cylinder 101, which is provided with a long opening seam from top to top along the axial direction; it also includes a new left door panel 202, a new right door panel 203 and a door opening Locking mechanism 204; the new left door panel 202 and the new right door panel 203 are respectively connected to both sides of the joint seam of the outer mold cylinder body 101; at least two left Door panel expansion seat 2021;

[0039] The door opening locking mechanism 204 includes a fixed inner channel steel 2041, a push-pull outer channel steel 2042, a linear drive element 2046, two opening and closing push-pull beams 2043, at least two pin shafts 2045 and several pairs of opening and closing connecting rods 2044;

[0040] The fixed inner channel steel 2041 in the door opening locking mechanism 204 is fixedly connected to the left door panel expansion seat 2021 and is parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com