Petroleum pipeline conveying device

A technology for conveying devices and oil pipelines, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., to achieve the effects of improving stability, reducing labor force, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

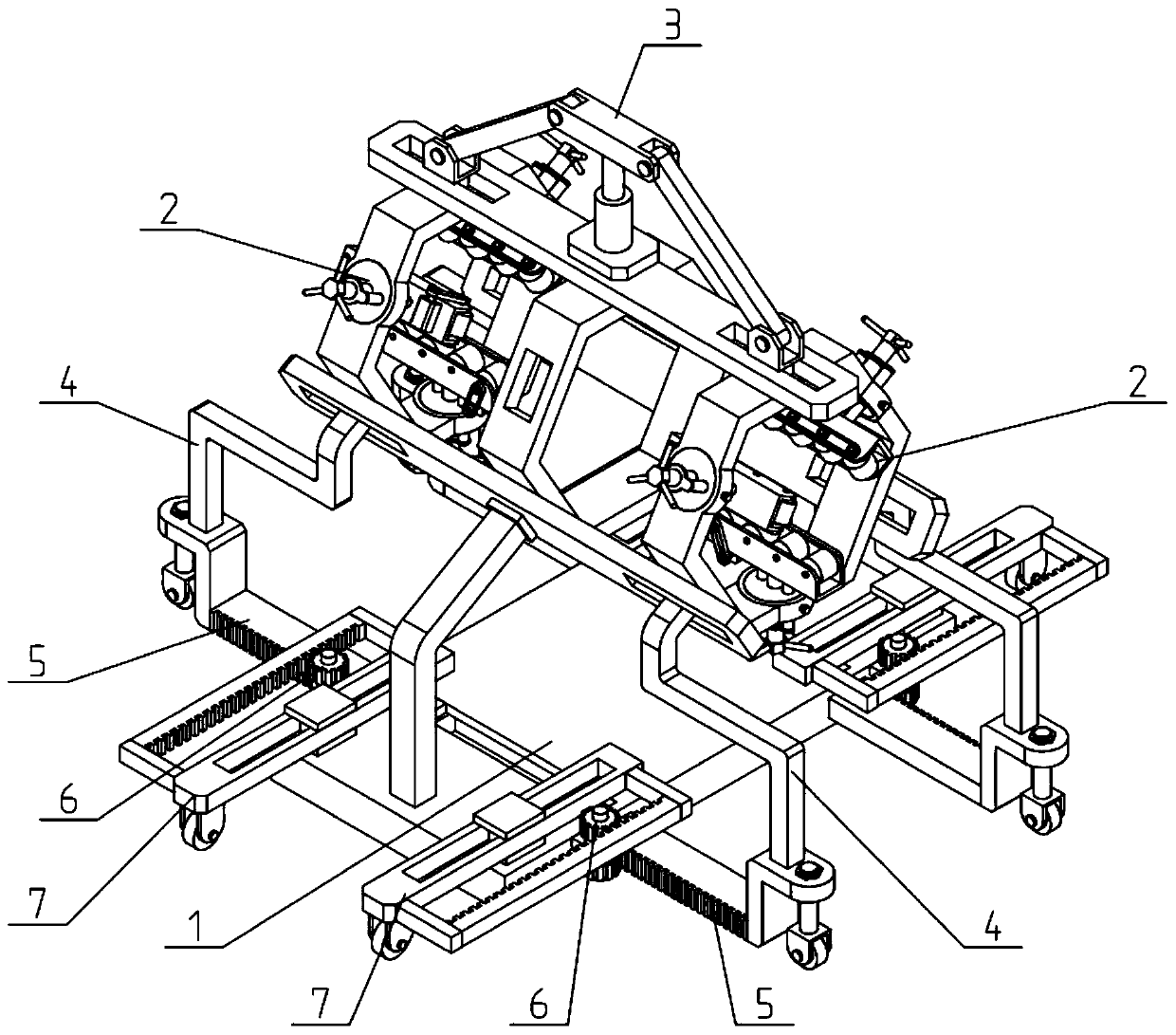

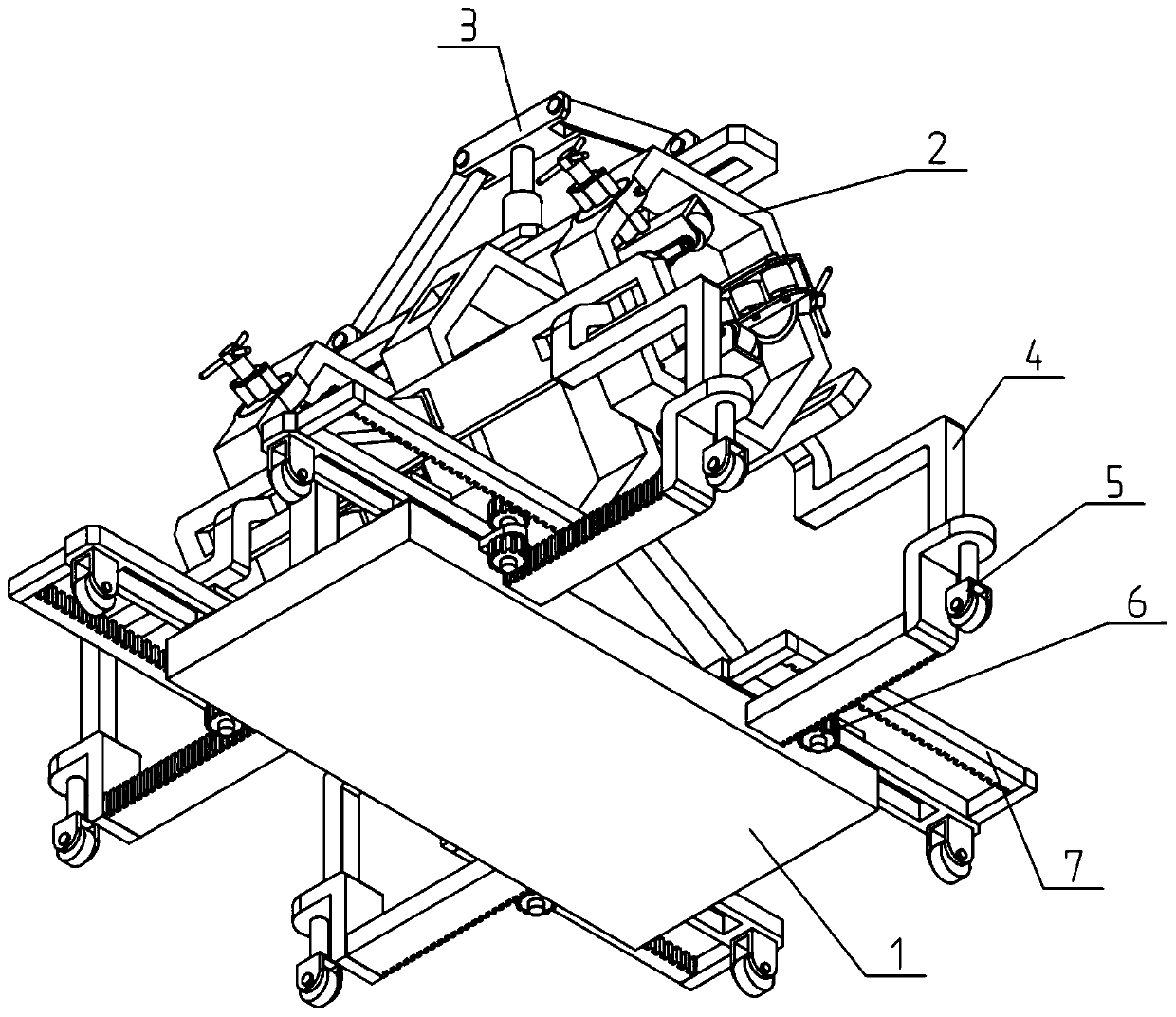

[0038] Such as Figure 1-13 As shown, the oil pipeline transportation device includes a bracket mechanism 1, a clamping and conveying mechanism 2, a spacing regulation mechanism 3, a bending connecting rod 4, a first auxiliary support mechanism 5, a transmission mechanism 6 and a second auxiliary support mechanism 7, and the bracket The top of the mechanism 1 is fixedly connected to the distance regulating mechanism 3; the distance regulating mechanism 3 is connected to the two clamping and conveying mechanisms 2; two ends; the two ends of the two clamping and conveying mechanisms 2 are respectively fixed to the upper end of one of the curved connecting rods 4, and the lower ends of the four curved connecting rods 4 are respectively fixed to one of the first auxiliary support mechanisms 5; the four first auxiliary support mechanisms 5 are respectively slidably fitted on both sides of the left and right ends of the support mechanism 1; The transmission mechanism 6 is fixedly c...

specific Embodiment approach 2

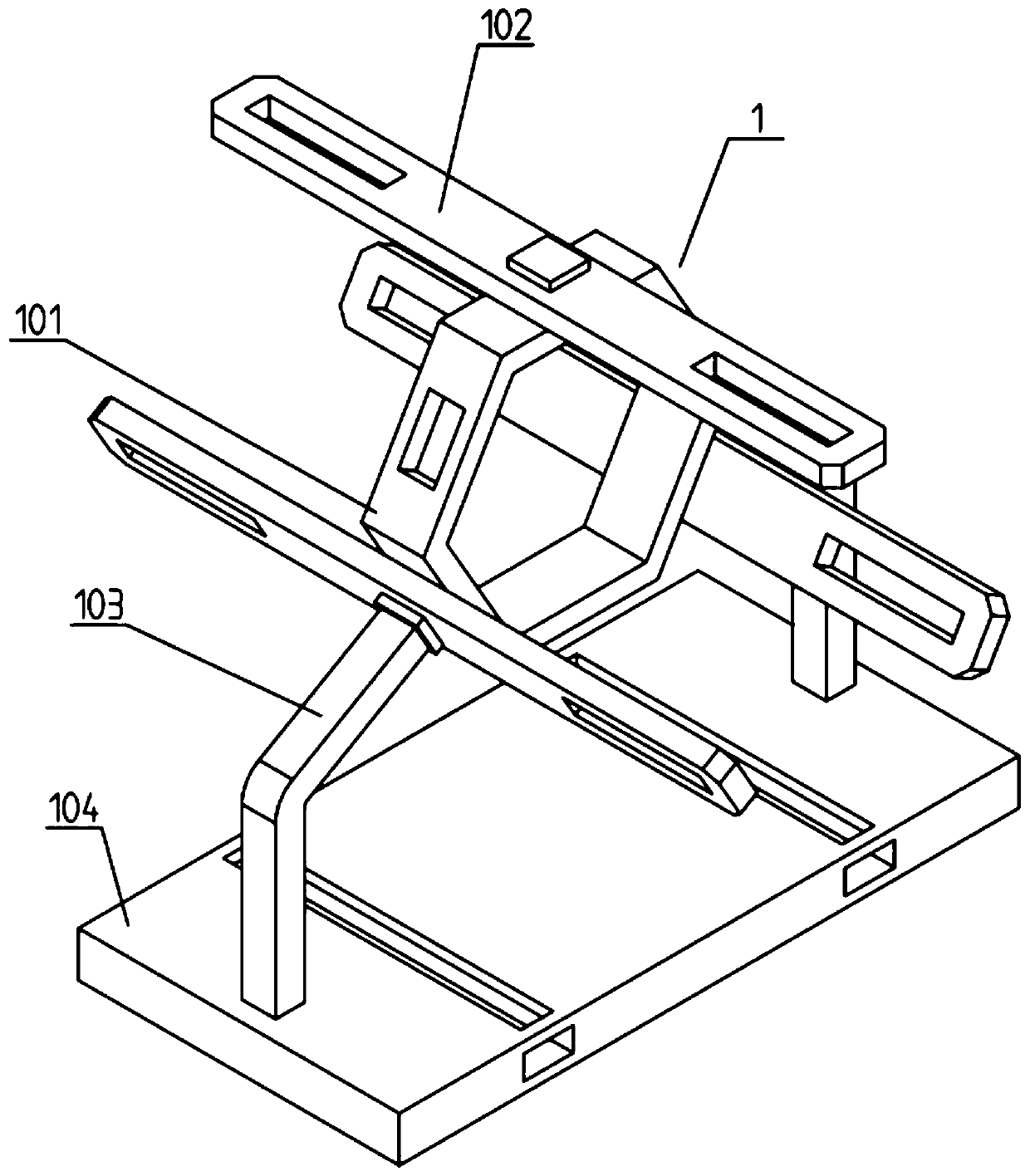

[0041] Such as Figure 1-13 As shown, the bracket mechanism 1 includes a fixed hexagonal frame 101, a guide frame plate 102, a curved bracket 103 and a bracket base 104; in the middle of the two guide frame plates 102 at the lower end respectively affixed to the top of one of the curved brackets 103, and the bottom ends of the two curved brackets 103 are symmetrically affixed to the two ends of the bracket base 104; Two ends of the guide frame plate 102 are respectively provided with a guide slideway.

specific Embodiment approach 3

[0043] Such as Figure 1-13 As shown, the distance control mechanism 3 includes an electric telescopic rod 301, a lifting control panel 302, an inclined connecting rod 303 and a linkage seat 304; The movable end of the electric telescopic rod 301 is fixed in the middle of the lifting control board 302; the two ends of the lifting control board 302 are respectively connected to the inner end of one inclined connecting rod 303, two The outer ends of the inclined connecting rods 303 are respectively rotatably connected to one of the linkage seats 304; the two linkage seats 304 are fixedly connected to the two clamping and conveying mechanisms 2 one by one. After the electric telescopic rod 301 is powered on, it can drive the lifting control panel 302 to carry out the lifting movement. When the lifting control panel 302 lifts and moves, it can drive the inner ends of the two inclined connecting rods 303 to carry out the lifting movement. The outer ends of the two inclined connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com