Laser-based automatic container grabbing system and method on container truck lane

A technology of container trucks and collection trucks, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of unrealized container automatic grabbing function and inability to realize fully automatic operation, and achieve convenient, fast and accurate alignment, safety and accuracy The effect of automatic capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

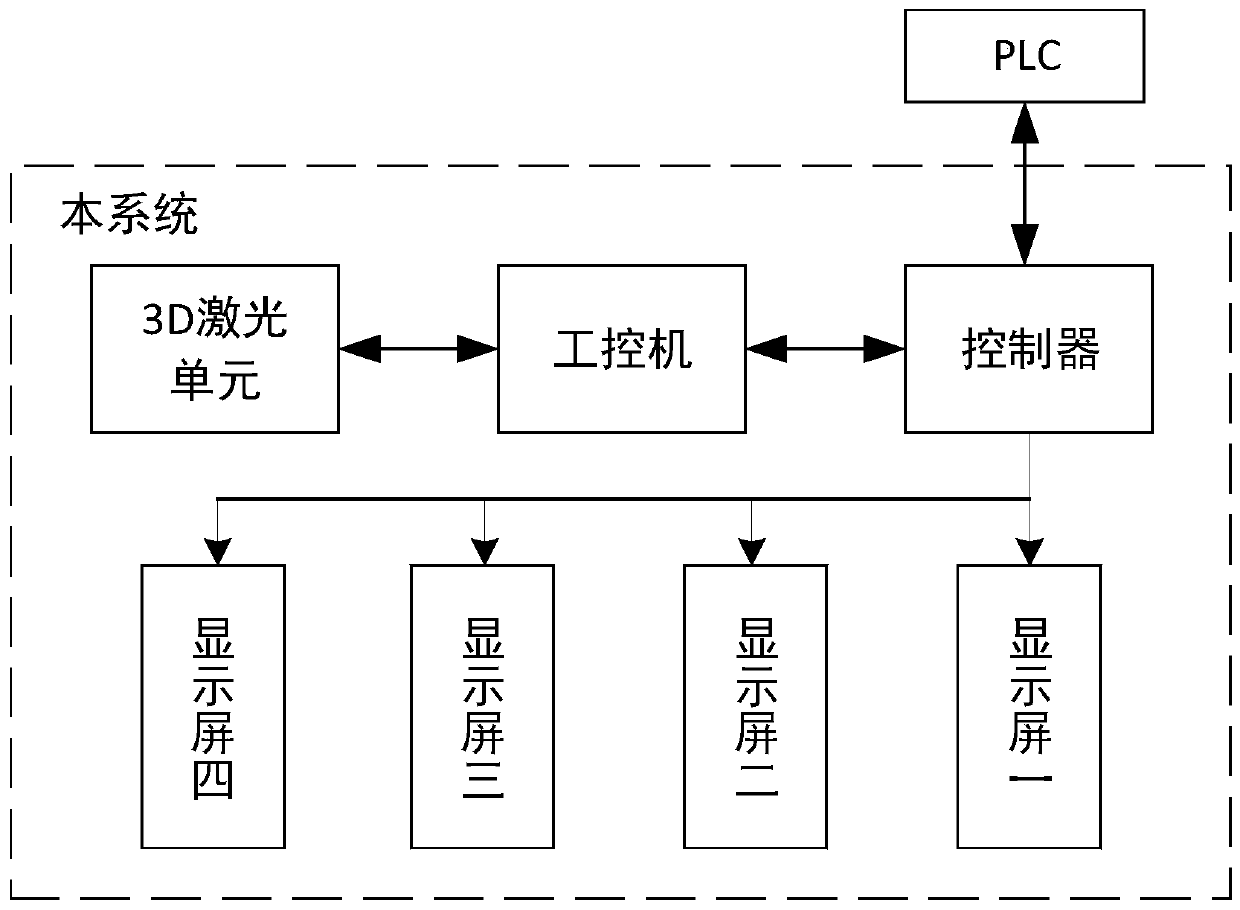

[0018] A laser-based automated container loading system on the lanes of container trucks, such as figure 1 As shown, including: 3D laser scanner, LED display, circuit breaker, switching power supply, router, controller and industrial computer, etc., among which:

[0019] The controller is respectively connected with the cart PLC, the 3D laser scanner, the industrial computer and the LED display, and the industrial computer is connected with the 3D laser scanner.

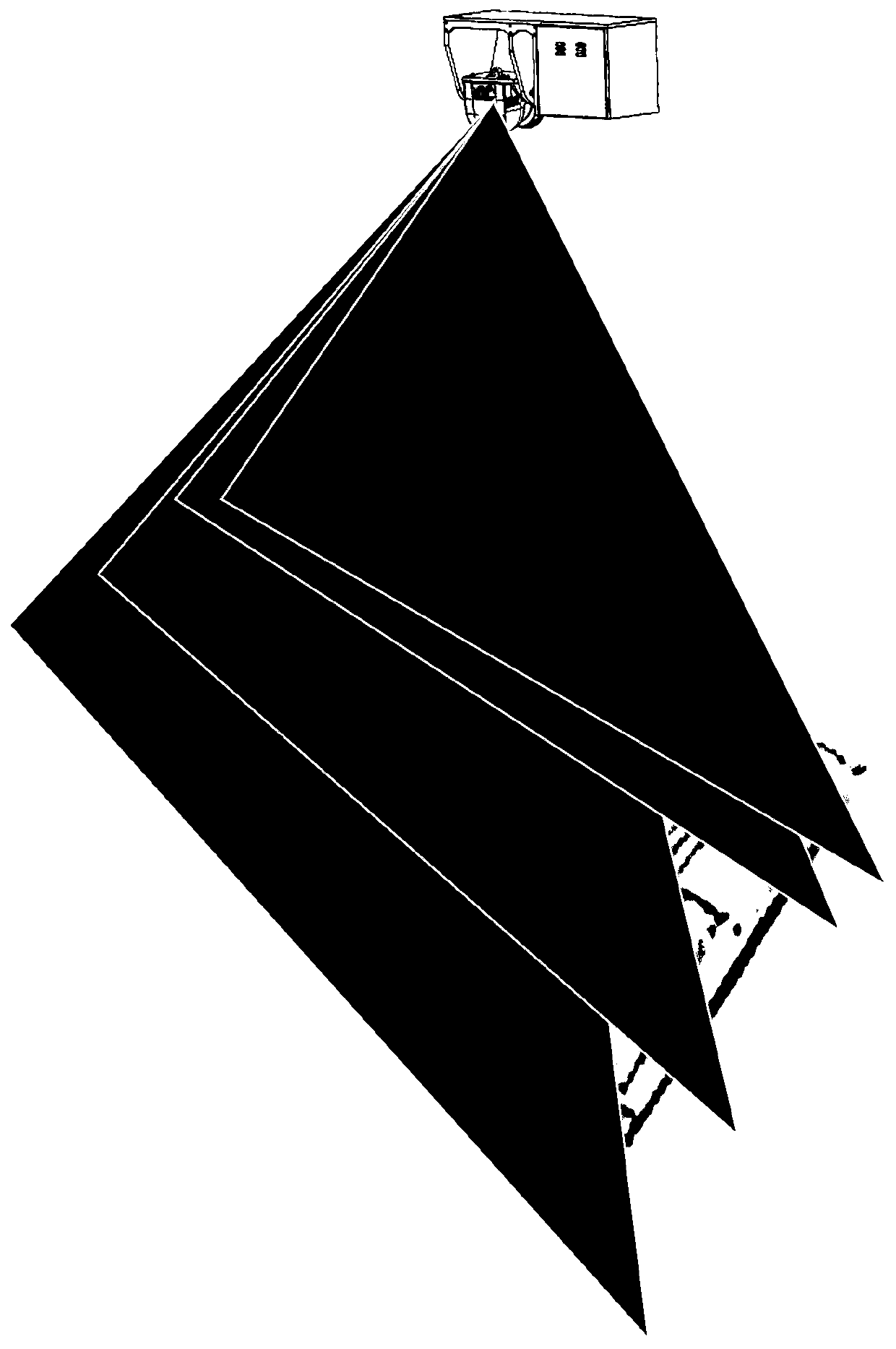

[0020] The 3D laser scanner is installed on the contact beam of the quay bridge or on the side walking platform of the yard bridge lane through the corresponding bracket to ensure that it can perform a complete 3D scan of the container truck. Its main function is to scan the container truck lane. Collect trucks for real-time scanning, the scanning effect is as follows Figure 4 shown.

[0021] The LED display screen is installed on the structure of the crane cart on the side of the driveway, ensuring that the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com